2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

The car's cooling system is the most important structure for maintaining the engine's operating power. In the famous cars of the Kama Automobile Plant, the coolant ranges from 80-1200C. Considering that the engine temperature reaches 220 0C, the special importance of the engine cooling system becomes even clearer.

Features and important elements

The KAMAZ vehicle, the cooling system of which practically does not differ from the classical one, works optimally. In the event of deviations, the car engine faces considerable trouble. The composition of the main elements of the system is almost the same as that of a passenger car:

- cooling radiator;

- water pump;

- pipes;

- thermostats;

- cooling fan.

One difference from the cooling system of non-truck vehicles is immediately visible - the presence of 2 thermostats. This is primarily due to the peculiarity of the structure of the engine. V-shapedthe figure eight has two cylinder heads located at an angle of less than 900 (hence the name). The next distinguishing feature is the shutters on the cooling radiator. In the cold season, they are in the closed position and allow the engine to warm up quickly.

The cooling system (KAMAZ 740) includes a hydraulic clutch for turning on the fan. The controlled drive allows you to automatically adjust the fan speed, thereby intensively cooling the engine.

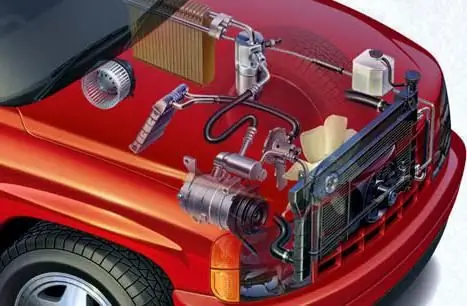

Scheme of the cooling system

The cooling system (KAMAZ 740) has a typical diagram, which makes it easy to imagine and understand the main points of work. The figure clearly shows that the car's cooling system is closed with forced circulation of antifreeze. The driving speed is dictated by the water pump (30). The coolant first flows into the cavity of the left row of cylinders, and then through the tube into the cavity of the right row of cylinders.

After the fluid passes through the cylinder heads, it will naturally heat up. The next element on the way will be the thermostat (17). Here, depending on the degree of heating, the liquid will go either back to the pump (small circle) or to the cooling radiator (10). The radiator (usually 3 or 4 rows) actively cools the antifreeze and completes the big circle by directing the coolant to the pump.

The scheme of the cooling system (KAMAZ) is shown in the figure. There is also an expansion tank (21) with a cap (22) and a liquid level control valve (20). The fan assembly with clutch (9) controls the speed and direction of the coolant flow. It turns on at a temperature of 850C. In general, the temperature of antifreeze during engine operation should be maintained in the range of 85-900C. To improve the direction of air flow through the fan, a diffuser is provided. If the temperature of the liquid in the cooling system (980С) is exceeded, the control lamp on the instrument panel will light up.

Weak spots in the cooling system

First, let's take a look at what can happen to a truck's cooling system. There really aren't that many problems:

- flow;

- antifreeze overheating;

- hypothermia;

- Coolant leaking into oil system.

Antifreeze leak occurs primarily through pipe connections, and lastly from the destruction (crackling) of rubber hoses. Therefore, one of the weak points of the system is the branch pipes. KAMAZ, whose cooling system is malfunctioning, begins to "suffer" and overheat. After all, if the coolant level drops, the overall heating of the system increases. It's close to overheating here. To fix the leak, it is important to carefully tighten and pressurize the entire system.

The second weak point can be identified thermostats. In the event of failure of this element, it is possible to both overheat and overcool the engine. It depends on what position the valve is stuck in. If the thermostat is open, the fluid "walks" in a large circle through the radiator. Whencold engine, this prevents the engine from heating up. If the shutters are also open, then the engine can be overcooled.

If the thermostat is closed, the antifreeze does not enter the radiator and heats up quickly enough on a hot engine. For some time, the fan (KAMAZ) saves the situation. The cooling system stops coping and overheats first the antifreeze and then the engine.

Third in line for weaknesses will be the clutched cooling fan. If it fails, the system will not pull out on passive cooling through the radiator. If you look after the car and do routine inspections in time with broach of “suspicious” places, then you should not expect any problems from the cooling system.

Cooling radiator (KAMAZ)

Consider all the main components of the cooling system separately. Let's start with the first thing that catches your eye - the radiator.

The cooling system (KAMAZ 5320) incorporates a 3- or 4-row cooling radiator. It is made according to the classical type and is:

- lower tank, to which the outlet pipe fits;

- central tube system arranged in several rows;

- top tank with inlet.

Three-point radiator mounting. On both sides, it is fixed with brackets, which, in turn, are attached to the frame spars through shock-absorbing elements. The lower radiator mount is connected to the 1 frame cross member.

A feature of the structure of the radiator (KAMAZ)is the presence of blinds. This is a mechanical system of metal plates that blocks access to the air flow through the radiator. Blinds are controlled by a simple cable drive directly from the cab. If the handle is pulled out, then the blinds are closed, otherwise they are open. Thanks to this, the engine warms up faster in the cold season.

Fan

The KAMAZ vehicle cooling fan is mounted on the hydraulic coupling shaft and is externally represented by five blades. Depending on the engine temperature, the clutch automatically engages and disengages. The fan, according to these inclusions, either also works, or in the case of a non-working fluid coupling, it passively spins under the influence of the air flow.

For more efficient airflow, the engine cooling system (KAMAZ) has a casing on the fan. It is made from a thin metal sheet by stamping. Thanks to him, the air effectively enters only the radiator without side suction.

Cooling system fluid coupling

The cooling system device (KAMAZ) incorporates such an important element as a fluid coupling. The main purpose of this device is to transfer torsion from the crankshaft of a car engine to a cooling fan. In the event of a sudden change in torque, the fluid coupling dampens vibrations, and the fan always runs smoothly, without jerking.

Structurally, the fluid coupling consists of two wheels rotating on the shaft through bearings enclosed in the housing. The number of blades is different: there are 33 on the driver, and 32 on the slave. Between the blades of the fluid coupling there isinternal cavity, which is working. It is through the working cavity that the torque is transmitted when it is filled with oil.

In order for the hydraulic coupling of the cooling system to work, it is necessary that engine oil enters it. This is due to the switch, which has three positions. 3 switch latches correspond to three fan operation modes:

- automatic;

- constant fan on;

- fan is completely off, the clutch does not transmit torque from the crankshaft.

In automatic mode, the cooling system (KAMAZ Euro 2) works according to the scheme developed by the designers. That is, up to a coolant temperature of 860С, oil does not enter the working cavity of the fluid coupling and the fan is turned off. And when the temperature rises, the switch opens, and oil enters the fluid coupling, thereby turning on the fan.

If the clutch switch is defective (engine overheated), it is recommended to set it to permanently open the fluid clutch. And after the malfunction is eliminated, return to automatic mode. For cases when the car overcomes deep fords, it is recommended to set the switch position in the closed state for the clutch.

Water pump

The cooling system (KAMAZ) has another important element - a water pump. Its main function is to circulate coolant throughout the engine cooling system. Without it, it will not be possible to create a forced flow in the right direction. And in case of its failure, the workengine will be in question.

Internal working cavities of the pump are reliably protected by seals. To prevent malfunctions, the pump has an oiler through which it is convenient to pump lubricant. A sign of filling is a control hole through which excess grease comes out. The usual "Litol" is used as a lubricant. In order to find out about the violation of tightness in the pump housing, there is a special drainage hole. If it flows from there, then the seals no longer hold and must be replaced.

Thermostats and fittings

The pipes of the cooling system (KAMAZ) should be well looked after. In the event of a leaky connection, it is possible to lose a large amount of coolant and overheat the engine. Particular attention should be paid to the connection points of the pipes at the radiator, water pump and thermostats.

The thermostats in the cooling system are responsible for controlling the flow of antifreeze. When the temperature of the liquid rises to 800С, it is redirected to the radiator, that is, the circulation begins to go in a "big circle". At the same time, part of the flow continues to flow in a "small circle". And only at a temperature of 930C, the "small circle" valve closes completely, and all the coolant begins to flow through the engine radiator.

Cooling system maintenance

The cooling system (KAMAZ 740) is practically no different from previous models. You should also know that for the 740 engine, the attachments are euro 0, euro 2, euro 3 and euro 4do not make changes to the cooling system. So, what needs to be done to best maintain the system?

The very first action that must be taken every day when the car is operated is to check the tightness of the entire system (watch for leaks) and add antifreeze to the recommended level. The coolant itself in the summer can be ordinary water, and in the winter it can be high-quality antifreeze or antifreeze. For operation in the harsh regions of the north, heating is installed in the cooling system.

Other scheduled maintenance activities include:

- check drive belt tension;

- water pump maintenance (bearing lubrication plus checking and replacing oil seals);

- Checking the drive belt tensioner;

- complete pressure testing of the cooling system;

- checking the quality of antifreeze and its possible replacement;

- flushing the system in case of severe clogging.

Crimping

The cooling system (KAMAZ 65115) must be completely sealed. A visual check is good, but it may not show places that are about to be missed. To identify such weak points, it is good to use a pressure gauge and a pump to create pressure.

For pressure testing, it is enough to apply pressure to the upper radiator inlet with a pump, start the engine and watch the pressure gauge reading. If everything is fine and there are no gaps in the system, the arrow of the device will not change its position. Otherwise, when the arrow starts to go down, it remains only to find the problematic place.

Coolant change

Cases when it is necessary to replace the entire cooling system fluid are not so rare. The easiest option is that winter has come, and there is plain water in the system. Also, replacement may be required if the fluid loses its cooling properties or is heavily contaminated.

The capacity of the cooling system (KAMAZ) is 25 liters. Of these, the water "shirt" accounts for 18 liters. To replace the fluid, the old one is first drained. To do this, it is necessary to open the lower radiator cock, the drain cock at the heat exchanger and the pump in the heating system, as well as the fluid supply pipes in the cabin heating system. Do not forget to unscrew the plug of the expansion tank.

After the liquid is completely drained, all taps are closed. And the entire volume of the cooling system (KAMAZ) is poured through the expansion tank. New antifreeze is selected depending on the time of year and the operating conditions of the car. At the same time, you should not delude yourself with imported options in beautiful canisters. Domestic coolants have exactly the same properties that meet international quality standards.

Flushing the cooling system

There are many ways to flush the cooling system. In case of slight contamination, you can rinse with plain water. To do this, the old coolant is drained, and water is poured instead. The engine starts and warms up at idle. After that, the water is drained, and the whole cyclerepeated several times until completely cleared.

If the contamination in the system is significant, it is best to use special ready-made flushes. At the same time, there are quick options when flushing is simply added to the old antifreeze, and then everything is drained. But it is better to use flushing solutions when the old coolant has already been drained. It should also be borne in mind that cleaning solutions for cleaning the water jacket of the engine will be different. The radiator of the cooling system should be flushed separately for more effective cleaning. For this, a 2.5% solution of hydrochloric acid has proven itself well.

From the features of flushing, you should know that the direction of the flushing flow must be opposite to the normal flow of the coolant. It will be more effective to flush the system with a stream of water or a pressurized chemical solution.

Troubleshooting

The cooling system (KAMAZ 5320) must work without deviation from inspection to inspection. But cases are different and malfunctions can occur unexpectedly. Knowing the weaknesses of the system will help you quickly identify the problem and solve it on the spot.

Violation of the tightness of the system is solved by finding the place of the leak and, if possible, eliminating it. For this, a visual inspection is often sufficient. All joints, water pump, radiator, coupling are checked. Worn-out nozzles are best simply replaced. A radiator leak can be eliminated by soldering or plugging leaky tubes. The decision to replace the radiator is made individually, because it is quite maintainable andrinses well when removed.

Wear or splitting of the drive belt when detected is best resolved by replacement. If there is a suspicion of poor-quality operation of thermostats, then it is convenient to check them by heating the lower radiator tank. At a temperature of 850С, that is, when the thermostat valve starts to open, the tank should warm up. If this does not happen, then the valve is defective and the thermostat should be replaced.

The cooling system (KAMAZ Euro 2) does not differ from its earlier versions and later ones too. The problems that can occur in the cooling system are the same in their characteristics. One of these malfunctions is the ingress of coolant into the lubrication system. It can be detected by descending antifreeze without traces of a leak. The cause may be worn cylinder head gaskets, as well as leaks through the block liner seals. The problem is solved by replacing worn engine gaskets.

Conclusion

Car care should be regular and comprehensive. None of its systems can have privileges. At the same time, knowing the weaknesses of a particular car helps a lot. KAMAZ, whose cooling system has no visible problems, should still be regularly inspected and have full maintenance.

Recommended:

Cooling system device. Branch pipes of the cooling system. Replacing the pipes of the cooling system

The internal combustion engine works stably only under a certain thermal regime. Too low a temperature leads to rapid wear, and an excessively high temperature can cause irreversible consequences, up to jamming of the pistons in the cylinders. Excess heat from the power unit is removed by the cooling system, which can be liquid or air

Chevrolet Niva: cooling system. Chevrolet Niva: cooling system device and possible malfunctions

Any car contains several basic systems, without the proper functioning of which all the benefits and pleasure of owning can be nullified. Among them: the engine power system, the exhaust system, the electrical system, and the engine cooling system

Car air conditioning system: diagnostics, repair, flushing, cleaning, system pressure. How to flush a car's air conditioning system?

The warm season is accompanied by frequent requests from car owners to service shops for such a service as diagnostics of the car's air conditioning system, as well as troubleshooting. We will understand the reasons for this phenomenon

Maintenance and repair of the engine cooling system. Soldering of cooling radiators

During the operation of the car engine, it heats up to sufficiently high temperatures, the cooling system is designed to avoid overheating. Repair, diagnostics and maintenance of this system are very important, as an overheated internal combustion engine will disable the car

Engine cooling fan. Engine cooling fan repair

When the engine cooling fan fails, it is urgent to change it. That is, remove, disassemble, repair and install back. This article shows you how to do it yourself