2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

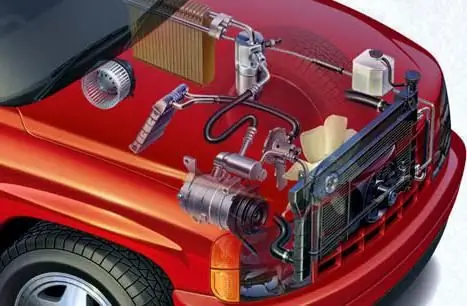

The cooling system is used to ensure the normal operation of the internal combustion engine. The normal temperature during operation is 85-90 degrees Celsius. Maintenance and repair of the cooling system, if necessary, must be carried out in a timely manner and with high quality, since the efficiency, reliability, and service life of the internal combustion engine depend on it.

General description of the system

In order to ensure the normal functioning of the engine, it is necessary that the cooling system maintains the desired temperature of the liquid. The need for repair may arise if the fluid in the system is in a state of constant and prolonged overheating or, conversely, hypothermia. In addition, repair of the cooling system is also mandatory if there is a fluid leak, as well as if there is a lot of noise during pump operation. Experts recommend checking the coolant level before every long trip.

In somevehicles, the fluid level is shown on the gauge marked MIN. If the arrow drops below this value, then you need to add fluid. It is necessary to check the level in the system with a cold engine, that is, before starting. Some cars have an alert system that monitors this indicator. In this case, if the level is too low, the driver will hear a beep.

System care and what not to do

There are a few things that are strictly forbidden to do, as this can cause malfunctions in the cooling system.

Firstly, it is strictly forbidden to add coolant to a hot engine. This is dangerous because cracks may occur in the cooling jacket of the cylinder block. If this happens, repair of the cooling system cannot be avoided.

Secondly, it is forbidden to start and briefly operate the engine immediately after the antifreeze or antifreeze has been drained from the system. This is dangerous because the O-rings of the cylinder liners may be destroyed.

It is worth knowing one more little fact - frequent water changes in the system leads to accelerated corrosion, as well as scale formation.

Diagnosis and repair of the cooling system in some cases can be carried out independently. For example, in the summer, it is important to keep the core of the radiator clean. If clogging of this area is noticed, then it must be cleaned with a jet of water or compressed air. The working jet must be directed towards the core from the fan side. If in the systemscale, rust or other deposits appear, it must be washed.

To avoid repair of the cooling system, seasonal maintenance should be carried out. When preparing the engine for winter, it is necessary to check the density of the coolant in the system using an instrument such as a density meter. It is necessary to choose the liquid itself very carefully, since if it contains impurities of petroleum products or they get there from other sources, all the liquid will begin to foam during heating. This will cause the engine to overheat, as well as leakage of the substance through the expansion tank or the radiator itself. Most often, antifreeze A-40 or A-65 is poured into cars. The crystallization temperature is -40 and -65 degrees Celsius, respectively, and the boiling point is about 108 degrees. Water must also be present in the liquid cooling system. However, its boiling point is much lower, and when the engine is running, after a certain time, it begins to evaporate altogether. It follows that, as a preventive measure, a small amount of distilled water should sometimes be added to the system.

Checking system status

If we talk about checking the technical condition of this system, then it lies in the fact that you need to determine the quality of its tightness and heat balance. It is possible to draw a conclusion about the tightness after a complete inspection of all mechanical parts has been carried out. You need to make sure that there are no leaks both with the engine running and with the engine off. In addition, it is important to monitor the rate of decrease of the substance from the expansion tank during the operation of the internal combustion engine.

As for the heat balance, it is possible to draw conclusions about its normal operation based on such factors as the engine warm-up rate, as well as maintaining the nominal operating temperature during the operation of the internal combustion engine. Repair of the cooling system is not required if complete tightness is ensured, and the engine temperature is between 80 and 95 degrees Celsius at a vehicle speed of 80-90 km/h.

Liquid leakage and pressure test method

Sometimes it also happens that leakage of antifreeze or antifreeze can occur due to the fact that the hoses of this system are not tightly connected with fittings and nozzles, stuffing box seals are worn out, cracks appear in tanks, etc.

There is a good way that can help check the general condition of the liquid cooling system, and also find out if there is a leak of the substance. To do this, successfully uses the method using pressure. To do this, you need to supply a small amount of pressurized air to the neck of the radiator or tank. If there are loose connections in any places, then liquid will begin to flow through them. Sometimes it happens that a leak occurs, but the tightness of the system is checked and it is in order. In this case, the problem usually lies in the incorrect operation of the radiator valve. If this happens, then it is important to check the condition of this part, and you also need to measure the pressure necessary to open it. The normal indicator is always indicated in the technical passport for the car. If there is a parameter deviation, thenthe cooling radiator needs to be repaired.

Electrolysis of aluminum parts

It is worth considering such a problem as electrolysis, which occurs if the car's radiator is made of aluminum, and the system also has a temperature sensor to turn on the fan. Electrolysis itself is a decomposition reaction of chemicals that occurs when an electric current passes through them.

There are several signs that indicate this problem:

- radiator pipe clogged;

- white coating appears around leaking places;

- a green coating appears near the thermal switch for the fan.

If these shortcomings appear, then it is necessary to check all the electrical connections of the devices in the system. If this is not done, then after a while you will have to repair the cooling radiator, as it will fail. It is worth adding that for aluminum fixtures, it is better not to use water as a coolant. It has a negative effect on aluminum, causing corrosion in the tubes of the system.

Faulty radiator and tank, how to fix them

Possible malfunctions of the cooling radiator:

- mechanical damage on tanks, which are expressed in the form of cracks, dents or holes;

- frame plates may crack or break;

- if the radiator was soldered, then in these placesthere may be fluid leaks;

- cooling plates or tubes may be damaged;

- System may become clogged due to scale or insects.

Repair of the auto cooling system in case of scale or contamination of the radiator begins with what is needed using a special installation and heated washing liquid to a temperature of 70-85 degrees Celsius to clean the system. Washing is carried out with ordinary water. To get rid of such a problem as sticking insects, you must use a special solvent. It is applied to the surface of the element, and then simply washed off with water.

As for the repair of barrels, everything is somewhat more complicated. For example, if a dent appears on a brass tank, then you can eliminate it with a mallet. First you need to lay the part on a wooden lining. If there are cracks, but they are not too large in size, then they can simply be filled with solder. If there is damage to the upper or lower expansion element of the system, then they are usually restored by installing patches. To install a patch in the internal combustion engine cooling system, you need to clean both the damage site and the patch, they are tinned, and then soldered to each other. Sometimes it happens that there are damages on the tubes and it is not possible to install a patch. In such cases, the problem can be fixed by soldering it from both ends. However, in this way, it is allowed to solder only three pieces for one radiator. If out of ordermore than 3 tubes, then they must either be replaced with new ones, or the radiator must be completely changed. If damage occurs on the radiator mounting plates, they can be repaired using gas-type welding.

Radiator leak problem

Sometimes it happens that fluid leaks, but all o-rings, joints and other elements are securely fastened. In this case, you need to check the radiator itself. Repair of the car's cooling system in this case is to identify the leak and fix it.

To identify the leak, you need to fill the radiator with water, close all the pipes with special plugs, after which air is supplied through the open pipe at a pressure of 1 kgf / cm. In the place where water appears and there is a fluid leak. Quite often it happens that access to the radiator is very limited, and it is quite difficult to check. To solve this problem, you will have to remove the part from the car.

- To begin with, the coolant is completely drained from the radiator and engine into a container.

- Next, you need to disconnect all the electrical wires that go to both the fan and the sensor for turning it on.

- After that, all remaining hoses from the radiator and from the expansion tank are disconnected.

- Followed by a rather difficult stage, at which you need to remove the casing guides. There are four of them - top, bottom, right and left. To remove the top mount, you need to remove the radiator from the special grooves to separate it from the rightclamp, you need to disconnect it from three mounts, on the left side from two more. The lower casing is attached directly to the radiator with three bolts that will have to be unscrewed.

- After that, the electric fan must be removed from the radiator without disconnecting it from the casing itself.

- At this time, the radiator will be held only by bolts that are screwed to the bottom bracket, they need to be unscrewed and the part removed.

- The last step is to remove the expansion tank, for which you need to unscrew one more bolt.

Repair of removed part

Once the desired part of the machine has been removed, you can use the same procedure as described earlier to find the leak. You can go the other way and place the radiator in a tub filled with water. Air bubbles will indicate the location of the breakdown. However, here you need to know a very important thing. Without coolant inside, the radiator should not be stored outdoors for more than two days, otherwise there will be a great risk of corrosion spreading. To avoid this, you can close all the holes with plugs or fill it with coolant that was drained earlier.

If, after removing the element, it was found that it is covered with scale or oil, and there is rust on the outside, then it must be blown out with compressed air. In addition, it can be washed with water, and the air channels can be cleaned with wooden studs, but very carefully. To eliminate holes in the radiator, from which the substance flows, use epoxy glue. Important to remember,that it is poisonous, and then you need to take care of the means of protection. You can apply it with a spatula, and on top of the applied layer you need to lay a strip of fabric, which will also be saturated with this composition. To make it much more convenient to lay the fabric, use tweezers.

Coolant pump

In the liquid cooling system there is a pump that pumps this very liquid. Naturally, it, like any other mechanical part, can break. Among the pump malfunctions are:

- bearing wear;

- blade deformation;

- impeller cracking;

- fluid leakage through the impeller seal.

If the oil seal has failed or the bearing has been damaged, then you need to repair the cooling system pump. It begins with the fact that you need to remove the device from the car and disassemble it. If severe wear became the cause of the breakdown, then the bearings are pressed from the roller, and the parts are washed in gasoline. The only exceptions are the sealing washers and the stuffing box. It is also necessary to check the surface of the end face of the housing sleeve. It should be perfectly smooth, without any potholes or other damage. If this is not the case, then the coating must be sanded. Next, you should move on to inspecting other parts of the roller. If the leakage occurs due to wear of the cuffs, then they need to be changed. The bearings and their seals should be inspected, and also replaced with new ones if the old ones are damaged.

Radiator soldering and air cooling

There is a way that can help eliminate microcracks and holes. Soldering of cooling radiators is consideredone of the best repairs. You can even do this work with your own hands. When soldering, it is very important that the solder fits as tightly as possible to the metal base of the radiator. For example, to successfully solder a brass cooling radiator, you will need the following equipment:

- electric soldering iron with enough power;

- acid for work;

- tin base solder;

- devices with which it will be possible to carry out mechanical cleaning of the surface before starting work.

All the right places will have to be cleaned to a metallic sheen. After that, you need to start surface treatment with flux (acid). The soldering iron must be well tinned and the place to be soldered must be well warmed up. After that, the solder is evenly distributed over the surface so that it fills all the cracks. This is how repairs are made by soldering.

Separately, it is worth mentioning the air cooling system of the engine. It does not make sense to consider its repair, since it is not installed on cars. There are several reasons why this is so. Firstly, there is no way to regulate the temperature regime, and secondly, while the car is stopped with the engine turned on, the oncoming air flow would decrease, which would lead to rapid overheating, and the inability to heat the passenger compartment. All this led to the exclusion of the installation of an air cooling system.

As for the cost of repairing the cooling system, it, of course, strongly depends on the make of the car and the severity of the problem. Most often, the cheapest procedures are diagnostics andreplacement of the temperature sensor (approximately 500 rubles each). The operation of replacing the radiator is considered the most expensive, especially if you have to remove the torpedo in the cabin. The minimum cost is 6500 rubles.

Recommended:

Cooling system device. Branch pipes of the cooling system. Replacing the pipes of the cooling system

The internal combustion engine works stably only under a certain thermal regime. Too low a temperature leads to rapid wear, and an excessively high temperature can cause irreversible consequences, up to jamming of the pistons in the cylinders. Excess heat from the power unit is removed by the cooling system, which can be liquid or air

Chevrolet Niva: cooling system. Chevrolet Niva: cooling system device and possible malfunctions

Any car contains several basic systems, without the proper functioning of which all the benefits and pleasure of owning can be nullified. Among them: the engine power system, the exhaust system, the electrical system, and the engine cooling system

Car air conditioning system: diagnostics, repair, flushing, cleaning, system pressure. How to flush a car's air conditioning system?

The warm season is accompanied by frequent requests from car owners to service shops for such a service as diagnostics of the car's air conditioning system, as well as troubleshooting. We will understand the reasons for this phenomenon

Engine cooling fan. Engine cooling fan repair

When the engine cooling fan fails, it is urgent to change it. That is, remove, disassemble, repair and install back. This article shows you how to do it yourself

Radiator leak: causes and their elimination. Soldering the engine cooling radiator

The engine cooling radiator is a very important part of a car. This system continuously removes excess heat from the motor and dissipates it into the environment. A fully serviceable heat exchanger is a guarantee of the optimum temperature for the engine, at which it can produce its full power without failures and problems