2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

In the process of using cars, motorists can have a variety of problems. It is especially unpleasant if, due to these problems, the ability to drive a car is lost. Sometimes the accelerator delivers serious difficulties. This is a device that is responsible for supplying a combustible mixture to the combustion chamber. It is very important to know its device, as well as the principle of operation. A distinction is made between mechanical accelerators and electronically actuated systems.

Modern cars are no longer equipped with mechanical systems. All of them have been replaced with electric accelerators. What does this mean for car owners? The electronic accelerator is easier driving. This is a big plus. There is also a minus - the owner of the car can no longer make decisions, or rather, he constantly independently adjusts the characteristics to suit his requirements. It turns out that it is far from always possible to obtain the desired mode of operation of the engine.

For inexperienced drivers, such a system provides a huge number of advantages. It's a safer ride. However, for more experienced motorists, the possibilities of electronics are not enough for a comfortable ride.

How the accelerator works

Mechanical accelerator is a drive,which moves the throttle. So the car adds speed. Since the drive is mechanical, the process takes place in several stages. The driver of the car presses the pedal while in the cabin of his car. Through the thrust, the force from the pedal is given directly to the throttle. The damper then moves.

Neither the mechanical system nor the electronic system can intervene and influence the throttle position in any way. In order to have an impact on acceleration and dynamic performance, it is required to change the engine torque. But there is an impact on the process of fuel injection and ignition. So, electronic systems can regulate engine operation modes only at idle or in cruise control mode.

As for the electronic accelerator, the principle of operation is still the same. One caveat - between the gas pedal and the damper itself there is a control unit that regulates the behavior of the engine.

The workflow here also takes place in stages. The driver of the car presses the pedal. At this time, the accelerator pedal sensor collects and transmits information about the angle and force of depression to the ECU. Next, the computer calculates what angle at this moment will be optimal for opening the throttle, and gives this information to the drive. The drive is also fully electronic and simply follows directions.

The electronic unit can make decisions to switch to more economical modes or to increase traffic safety performance. ittaken into account, calculated and switched on by the computer due to the opening of the damper. The driver cannot completely influence his car, since the ECU and the accelerator sensor took over most of it. Even if the driver does not touch the pedal, the unit can still change the characteristics of the motor by opening or closing the throttle.

How the accelerator works

Many beginners are wondering why this device is called an accelerator, because it is a gas pedal. Everything is simple. The accelerator pedal is only part of a larger mechanism. The word itself is translated as "acceleration". And you need to understand what is meant by a special damper, which is responsible for supplying the air-fuel mixture to the engine cylinders. The wider the throttle valve is opened, the more pressure will be in the combustion chambers and the faster the pistons will move. The pistons transmit force to the crankshaft, and then the energy of its rotation goes to the transmission. When the driver changes gear, he controls the speed of rotation of the wheels of the car. All these processes together make the car move.

Carburetor and injector

Both on the injection engine and on the carburetor, the accelerator works almost the same. The difference is quite small. And this difference is in the way the fuel mixture is supplied. A carburetor is nothing more than one of the nodes of the fuel system where the combustible mixture is prepared. The driver, pressing the accelerator pedal, controls and also regulates the amount of mixture supplied to the cylinder block.

On injection engines, the difference is that this is a whole systeminjection. The volume of fuel supplied to each cylinder is regulated here using injectors. The mixture is delivered more precisely. You should be aware that the injection system can be with distributed or direct injection.

Diesel units

Here is a separate injection system. The combustible mixture is injected into the cylinder block constantly. In this case, only the amount that is fed into each of the chambers can be controlled.

Design of electronic throttle actuator

Perfect systems consist of a large number of different components. A perfect system is more accurate. This can be said about modern throttle actuators. The device consists of several systems.

Pedal module

This is directly the pedal and the accelerator pedal position sensor. It is he who determines the position of the pedal and gives this data to the ECU. This sensor consists of two variable resistors that measure resistance depending on the position of the accelerator. It constantly monitors the frequency and amplitude of pressing the pedal and not only monitors the fuel supply, but is also an engine idle sensor.

Accelerator position sensor

The potentiometer consists of a variable and a constant resistor with a resistance of about 8 kOhm. One of the terminals is energized at 5 V. The middle terminal tells the sensor what position the pedal is in. If the voltage of this signal is less than 0.7 V, then the damperconsidered closed, if more than 4 V, then the ECU considers the damper open.

Control unit

The electronic control unit receives signals from sensors and, based on these data, learns the desire of the driver regarding the speed of the car. To implement this, a control signal is applied to the damper actuator, which, depending on the signal, closes or opens.

Damper Control Module

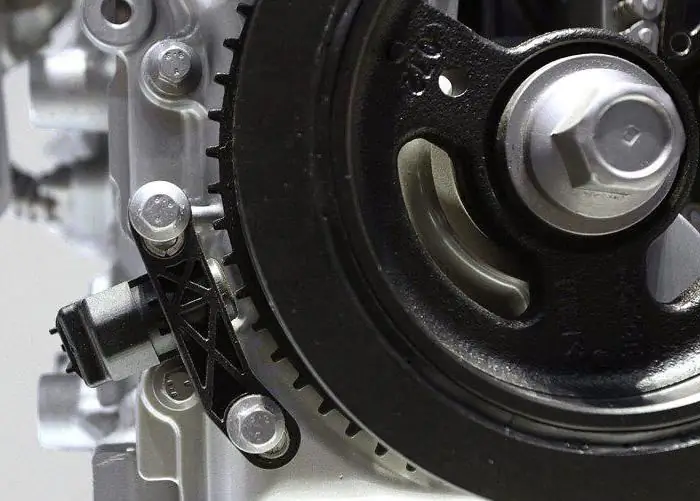

This system provides the required amount of air to the cylinders. In addition, it also gives information to the computer about the position of the damper at the moment. The system includes angle sensors.

Mechanical throttle actuator

These designs are used in domestic cars, as well as in inexpensive foreign cars.

At the heart of the drive is the accelerator cable. The drive also consists of rotary levers. When the driver presses the pedal, the damper rotates, thereby opening air. This type of drive also has a manual control system in the form of a braided cable and a lever on the carburetor. When you press the pedal, the force of the return spring is overcome, which acts on the thrust and accelerator cable and regulates the throttle. The throttle section increases, along with this, the air supply also increases.

Typical malfunctions

It may be limited maximum power of the power unit, uneven idle speed. It is also possible that the motor stops when the leg is suddenly released withpedals. All these are frequent malfunctions of any accelerator.

Competent operation

The electronic accelerator is an intelligent device. There are rules for its use.

So, you should not push the pedal hard for no reason. It must be remembered that with each sharp press a large amount of fuel is consumed. The average consumption will increase to eight liters. If you want to pick up speed faster, the engine will increase the "appetite" by 3 times.

So, we found out what an element such as an accelerator is for.

Recommended:

Phase sensor "Kalina". Replacing the phase sensor

Using the phase sensor, it is possible to track the position of the camshaft. It is not installed in carburetor engines; they were not on the first copies of injection systems either. But it can be found in almost all engines with 16 valves. An eight-valve engine is equipped with such devices only if they comply with Euro-3 toxicity standards, have a phased or sequentially distributed injection of the fuel mixture

Throttle position sensor: characteristic, principle of operation

So, the throttle position sensor is a very important element of the car. Therefore, you should get acquainted with the principles of its work

How does the crankshaft position sensor interact with other car parts?

Each car, regardless of the year of manufacture and brand, is certainly equipped with such a detail as a crankshaft position sensor, which ensures the smooth and uniform operation of the engine

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

TPDZ - what is it? DPS adjustment. Throttle position sensor

Modern car consists of many components and assemblies. And even a malfunction of the smallest of them can lead to very serious consequences. One of these small components is the throttle position sensor (TPS). What is this part and how to determine its malfunction?