2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

One of the most vulnerable places in the car are thresholds. They are most often exposed to adverse factors. And most often, rust on a car body begins precisely from the thresholds, quickly dispersing throughout the body. How to avoid this and what kind of threshold protection exists at this time, we will tell in this article.

What is a car threshold?

In simple terms, the threshold in a car is a strip that runs under the car door between the front and rear fenders. Roughly speaking, to see the threshold, you need to open the car door and look down - this is exactly what the threshold is. And we will talk about their protection.

Ways to protect the threshold

- Using an aerosol coating.

- With overlays.

- Using screen protectors.

- With the help of mastics and varnishes.

- Using liquid lockers.

Now let's look at each method in more detail.

Spray Coating

SuchDo-it-yourself way to protect the thresholds with your own hands is the most economical, but not particularly durable. No matter how carefully you apply the product, you are unlikely to achieve a perfect glossy surface, which means that dirt will constantly accumulate in the slightest irregularities, which will eventually cause the coating to peel off.

- BODY-950. Resin-based anti-corrosion spray. Such a spray is quite resistant to external damage and dries quickly, but it must be applied with a special gun.

- "Eltrans". The low cost of this anti-gravel aerosol and application immediately from the can makes it quite popular among car owners. The tool is quite effective with economical consumption. It takes about 400 grams of product per square meter, subject to painting in one layer. For greater effectiveness, it is recommended to apply two to three layers.

- Kerry. Pretty high-quality protection of the thresholds of the car, which does not require any special skills to use. Has high adhesion to the surface.

Of course, there are a lot of such aerosols, they all have both pluses and minuses. We have brought the most famous and noteworthy. Such threshold protection can also be carried out as an auxiliary in addition to the main methods.

Before processing, thresholds should be thoroughly washed and dried. If there are traces of rust, they must be cleaned with a metal brush or sandpaper. And only after that apply an aerosol. If you are using rust and stone chip protection, the rust preventative must be applied first.

Overlays

Sills as protection of thresholds of the car have not only protective, but also decorative properties. They effectively protect the car from harmful effects and are a beautiful and effective way of tuning.

Usually they are made of metal, often chrome, but there is also a plastic protection of thresholds. The last option is the cheapest, but also the most short-lived. In addition, under a plastic body kit, metal can rust much more than without it at all. This is due to the fact that if there is no air access, it seems to “sweat”, respectively, the risk of corrosion increases.

Metal lining, on the contrary, is quite strong and reliable.

In general terms, a sill protector is a kind of "entrance mat" on which all street dirt, chemicals from our roads and other debris settle.

Another plus of using a sill protector is that it is very easy to install and replace. For this, you do not need to involve specialists. Agree, it is better to periodically change such pads than to subsequently pay for a full repair of thresholds.

As you can see, such protection has many advantages, but there are also disadvantages. First, it is a constant additional cost. And secondly, such pads are not suitable for all car models. Sometimes motorists complain that after installation it became inconvenient to get into the car - this is especially true for cars with lowlanding. Well, the third minus is that if you install the linings inaccurately, you can deform the body and damage the thresholds, so all actions must be performed carefully and slowly.

Another option for protecting sills is a pipe that acts like a sill but does not require drilling into the body.

Protective film

Such a film is used not only as protection for the bumper and sills, but also for the entire body, or rather for those parts of it that are most exposed to harmful effects.

Protective film is different, depending on its purpose. To protect the thresholds, they usually use anti-gravel.

The advantage of such protection is that assembly and disassembly do not cause any damage to the car. In addition, it is quite durable and reliably protects the car from damage. To paste over the thresholds with such protection is quite within the power of the car owner himself. All you need is patience and free time. But if you really want to cover the entire body of the car with high quality, then it is better to turn to specialists.

The disadvantage of such protection is that:

- Wrapping a non-new car will show all the chips and scratches on the body stronger.

- If the work is poor, there is a high probability that the film will peel off quickly.

- If you do not wash the car, then the film quickly turns yellow from dirt.

The film is vinyl and polyurethane. The first is short-lived and protects the car only due to its thickness. Quite rough and unplasticat low temperatures or with a strong impact may break. Polyurethane, on the contrary, is quite expensive, but of high quality. Protects not only from small scratches, but also from sand, stones, etc., very elastic and resilient, reminiscent of rubber. Tolerates operation at low temperatures. Polyurethane is about five times more expensive than vinyl.

Varnishes and mastics

Protection of thresholds in this way is within the power of the car owner himself. The involvement of service stations is usually not required. Working order:

- Wash and dry the vehicle thresholds thoroughly.

- Remove the outer thresholds so that all parts that need to be processed can be accessed. Clean the sills from the inside.

- Remove old anti-corrosion coating, peeled paint. If there are traces of rust, then they need to be cleaned off until undamaged metal appears.

- Degrease the sills with acetone or petrol and apply rust remover.

- Making tape to seal the places that will not be treated.

- Apply dressing primer.

- Process thresholds with protective equipment.

- Leave for two to four hours until completely dry.

The most commonly used for such work:

- Aerosol, bitumen, polymer-bitumen mastic.

- Movil.

- Bitumen varnish.

- An oil-based material with anti-corrosion property.

- Rubber based stone chip protector.

Liquid Locker

Liquid locker is a densea viscous paste that, after being applied to the thresholds, hardens and resembles rubber or elastic plastic in properties.

Pros of this method of protection:

- Resistant to mechanical stress.

- It's pretty easy to apply, even on hard-to-reach places.

- The locker is plastic and uniform.

- Moisture resistant to prevent condensation from accumulating in the car.

- Environmentally friendly.

- Grips well and has a high threshold of adhesion to the surface of the car, does not form sags.

- Tolerates high and low temperatures well.

- Has soundproofing properties.

This method of threshold protection takes place in three stages:

- Using a brush or spatula, apply the first layer of anticorrosive and dry.

- Apply a second layer of bituminous mastic and dry.

- Spray anti-corrosion rubber with the third finishing coat.

Each layer should be 1.5-2.5 centimeters thick. Such a coating fully sets in about two days after application, so it is better to refrain from driving at this time.

Conclusion

As you can see, there are a lot of ways to protect thresholds, and they all have their pros and cons. Which one to choose is up to you. But if you are not confident in your abilities, then it is better to contact the service station - let the specialists do the work for you with high quality so that you do not have to spend money on correcting your mistakes.

Recommended:

Electro-turbine: characteristics, principle of operation, pros and cons of work, do-it-yourself installation tips and owner reviews

Electric turbines represent the next stage in the development of turbochargers. Despite significant advantages over mechanical options, they are currently not widely used on production cars due to the high cost and complexity of the design

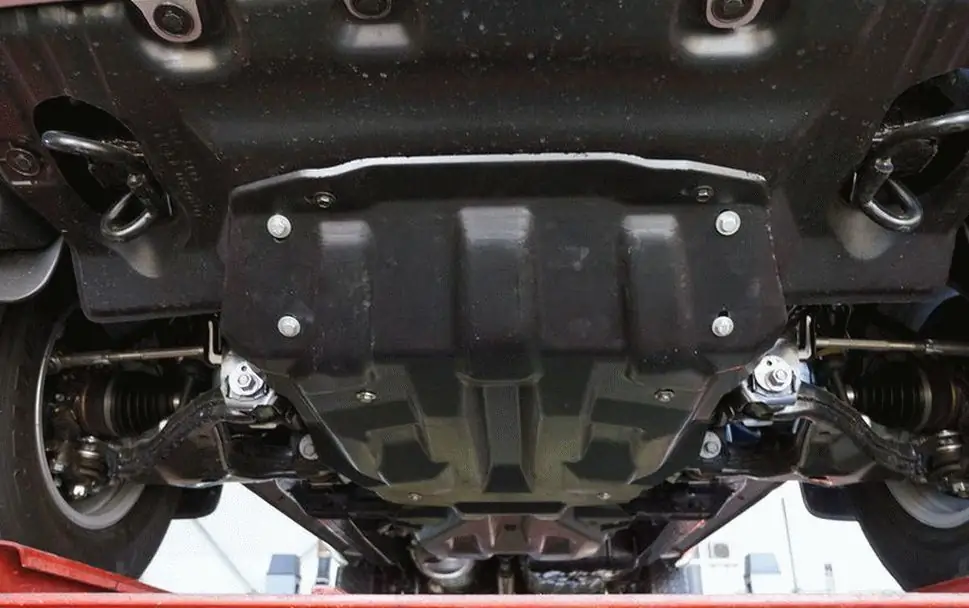

Composite crankcase protection: characteristics, principle of operation, pros and cons

The need to install crankcase protection has not been disputed by car owners for a long time. The bottom of the car covers various important units, including the transmission, transfer case, engine crankcase, chassis components and parts, and much more. Hitting any obstacles can damage them. To avoid this, crankcase protection is installed - metal or composite

Contract engine: how to understand what it is? Definition, characteristics, features of work, comparison, pros and cons

If the engine is out of order and it is impossible to overhaul, then the question naturally arises, where and what kind of engine to buy. A contract engine is a good alternative to a new original one and is much better than a used engine from disassembly

Air suspension for UAZ Patriot: description, installation, pros and cons, reviews

Air suspension on the UAZ Patriot: device, advantages and disadvantages, reviews. Air suspension on "UAZ Patriot": installation, photo

RB-engine from NISSAN: model, characteristics, features, pros and cons of operation

The RB engine series was produced by Nissan from 1985 to 2004. Although these 6-cylinder inline engines were installed in a relatively small number of models, they gained great fame, primarily due to sports options such as the RB25DET and especially RB26DETT. They are still widely used in motorsport and tuning to this day