2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

With tightening environmental regulations, automakers are being forced to develop ways to improve the environmental friendliness and efficiency of engines while maintaining performance. In this regard, forced induction systems have become widespread. Whereas in the past they were used to increase productivity, they are now being used as a means of improving economy and environmental friendliness. Thanks to supercharging, you can achieve the same performance as on atmospheric engines, with fewer cylinders and a smaller volume. That is, supercharged engines are more efficient. Another method is the use of electrical energy both separately (electric motors) and in combination with internal combustion engines (hybrid power plants). This article discusses electric turbines that combine these approaches.

General Features

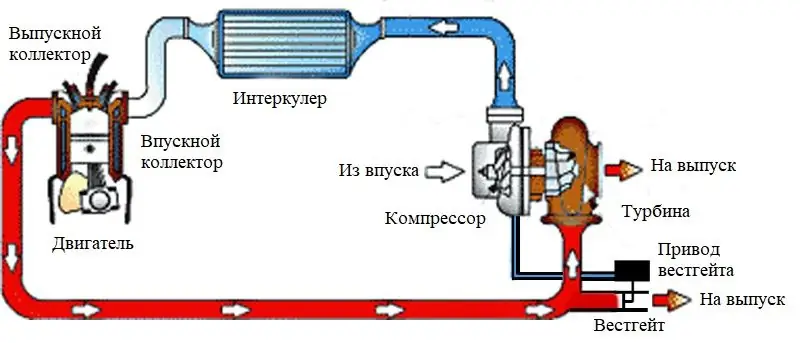

Non-electric forced induction systems according to the energy source are classified into turbochargers and superchargers. Electrical systems build on them and aim to improve performance during transients.processes and minimizing lags.

The electric blower, according to Honeywell, is a compressor driven by an electric motor that is mounted on a supercharged motor. That is, this is an additional device for a turbo engine. An electric turbine is an analogue of a mechanical turbine. The drive in this case can be implemented in different ways.

According to the classification of researchers at the University of Wisconsin-Madison, electrical systems of forced induction are differentiated into the following types by design and principle of operation:

- electric blowers (EC/ET/ES);

- turbines with electric assistant (EAT);

- electrically separated turbines (EST);

- turbines with additional electrically driven compressor (TEDC).

Design

The above types of electric turbines have a different device. This is in different layouts of components, in differences in their technical parameters, etc.

EC

EC is an electric motor driven compressor. This is the electric blower mentioned above. The electric drive provides the greatest control flexibility and the ability to operate the compressor at the optimum operating point. However, this requires powerful electrical components.

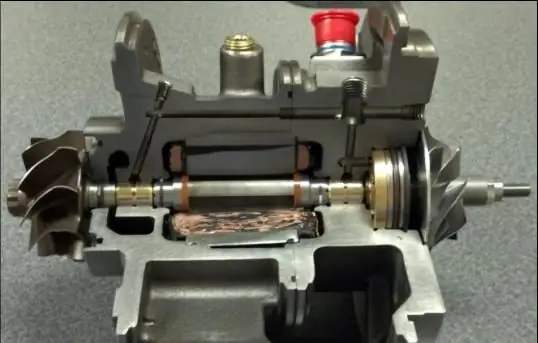

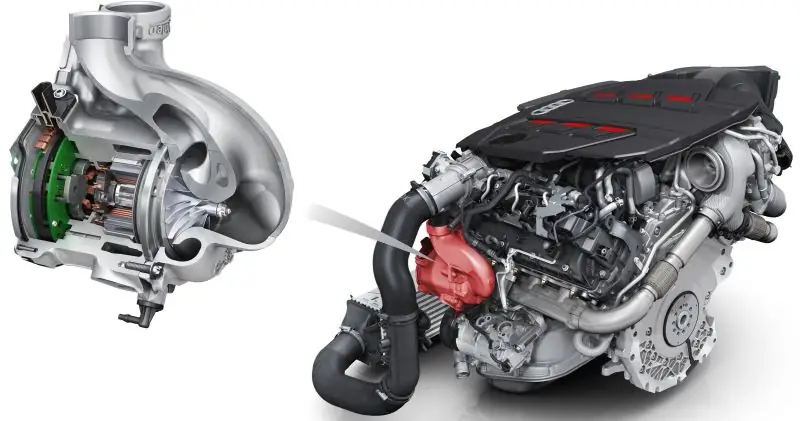

EAT

In EAT, a high-speed electric motor is mounted between the turbine and compressor, usually on a shaft. Due to the fact that it is not the main source of energy, are usedlow power electrical components. This results in a low cost. In addition, such turbochargers have the ability to self-detect the position of the rotor and are characterized by good generating and motoring capabilities. The main problem is the high temperature effect on the electric motor, especially if it is installed inside the housing.

There are various methods to solve it. For example, BMW installed clutches to allow the electric motor to be connected and disconnected from the shaft. Thanks to this, the motor can be placed outside the turbine. G+L inotec used a permanent magnet motor with a large air gap, which can also be located outside. The inner diameter of the stator is equal to the outer diameter of the compressor, and the outer diameter of the rotor is equal to the output diameter of the shaft. The air gap may act as an air inlet. This provides advantages in terms of cooling, inertia and thermal effect. In addition, in terms of thermal stability and thermal control, induction electric motors with variable magnetic resistance, universal collector motors are more preferable in comparison with a motor with surface permanent magnets.

EST

In EST, the turbine and compressor are not connected by a shaft, and each of them is equipped with an electric motor. This allows the compressor and turbine wheels to operate at different speeds. This design has similar advantages to ET, but, unlike it, is able to generate energy. In addition, sheIt has less thermal effect due to the separation of the compressor and turbine, as well as the absence of additional inertia from the turbine and its shaft. Separating the turbine and compressor is advantageous from a packaging point of view, as it allows the air flow path to be optimized. However, this technology also requires a powerful electric motor, generator and inverters to meet the torque/inertia ratio, which comes at a cost.

TEDC

TEDC is a mechanical turbine with an additional compressor driven by an electric motor. According to the location of the compressor relative to the turbine, these systems are classified into options upstream and downstream (above and below the turbine, respectively). In general, they are characterized by significantly better responsiveness during transients at the "bottom" due to the independence of the electric motor from the inertia of the turbine and shaft. Moreover, downstream TEDCs are superior in this regard to upstream options due to the fact that the latter are characterized by a large volume to maintain pressure. Another advantage of this type of electric turbines is the minimal differences from mechanical ones.

Operating principle

The above types of electric turbines differ in the principle of operation. So, the drive is implemented differently, some of them are able to generate energy, etc.

EC

In EC, the compressor is driven by an electric motor. Such a system is not capable of generating energy, but for itsstorage can be combined with a regenerative braking system or a built-in starter generator.

EAT

In the EAT at low rpm, the electric motor provides additional torque to the compressor to boost boost pressure. At the "tops" it generates energy that can be transferred to storage. In addition, the electric motor can prevent the turbine from exceeding its speed limit. However, a high back pressure effect may occur, which compensates for the energy extracted from the exhaust gases.

Due to the possibility of generating electricity from exhaust gases, such turbochargers are called hybrid. On passenger cars, depending on the driving cycle, they can generate from several hundred watts to kW. This allows you to replace the alternator while saving fuel.

EST

In EST, the energy of the exhaust gases does not drive the compressor directly, but is converted into electrical energy using a generator. The compressor is driven by stored energy.

TEDC

In TEDC, the electric motor functions independently of the turbine, and the additional compressor driven by it serves to increase the boost at the "bottom".

Design and functional differences

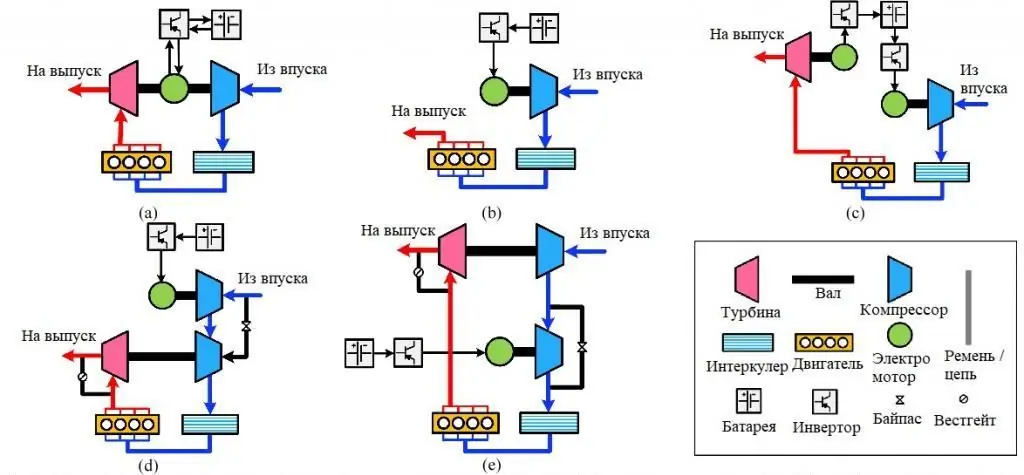

The fundamental differences between the considered electrical systems of forced induction are combined by researchers at the University of Wisconsin-Madison in graphical and tabular form. The figure below shows the diagrams of their device (a - EAT, b - EC, c - EST, d - TEDC upstream, e - TEDC downstream).

The table reflects the main provisions of the device. These include the source of energy, the drive of the compressor, the power of the electrical components. In addition, qualities such as dimensions and temperature effect are important.

| Type | EC | EAT | EST | TEDC |

| Power source | Battery | Exhaust gases / battery | Exhaust gases / battery | Exhaust gases / battery |

| Power of electric motor and inverter | High | Low | High | Low |

| Temperature effect | Low | High | Low | Low |

| Size | Small | Medium | Big | Big |

| Electric turbine | No | Yes | Yes | No |

| Turbo-electric compressor drive | No | Yes | No | No |

Thus, EAT and EST technologies belong to electric turbines. EC as it wasnoted - a separate mechanism, TEDC - a conventional turbocharging system equipped with it.

Pros and cons

Turbine drive by an electric motor eliminates the main disadvantages of mechanical turbochargers.

- No lag as the electric motor can spin up the rotor very fast.

- There is no turbo lag caused by a lack of exhaust gases, since in this case the electric motor compensates for the lack of energy.

- The electric motor allows you to keep boost during transients like anti-lag without the negative effects of the latter.

- This provides a wide operating range and consistent torque.

- Some types of these mechanisms can generate electricity, reducing the load on the generator and reducing fuel consumption.

- Recovery of lost energy is possible, as Ferrari implemented in the Formula 1 engine.

- Electro-turbines operate in more gentle conditions and at lower speeds (100 thousand instead of 200-300 thousand).

However, this technology has a number of disadvantages.

- Great design complexity including motor and controllers.

- This causes a high cost.

- In addition, the complexity of the design affects the reliability.

- Due to the large number of structural elements (in addition to the turbine, this includes an electric motor, controllers, battery), these turbochargers are much larger and heavier than conventional ones.

In addition, each type of electric turbine is characterizedspecific features.

| Type | EC | EAT | EST | TEDC upstream | TEDC downstream |

| Dignity |

|

|

|

|

|

| Flaws |

|

|

|

|

|

In terms of durability, according to IHI, electric turbines will be equivalent to mechanical ones due to operation in the same conditions in a more gentle mode with greater design complexity.

Relevance

Despite good performance, electric turbines are currently not widely used on mass-produced cars. This is due to their high cost and complexity. In addition, improved versions of mechanical turbines (twin scroll and variable geometry) have similar advantages over the initial modifications (albeit to a lesser extent) at a much lower cost. Now EST uses Ferrari in the Formula 1 engine. According to Honeywell, the mass use of electric turbines will begin at the beginning of the next decade. It should be noted that electric superchargers are already used on some production vehicles, such as the Honda Clarity, as they are simpler.

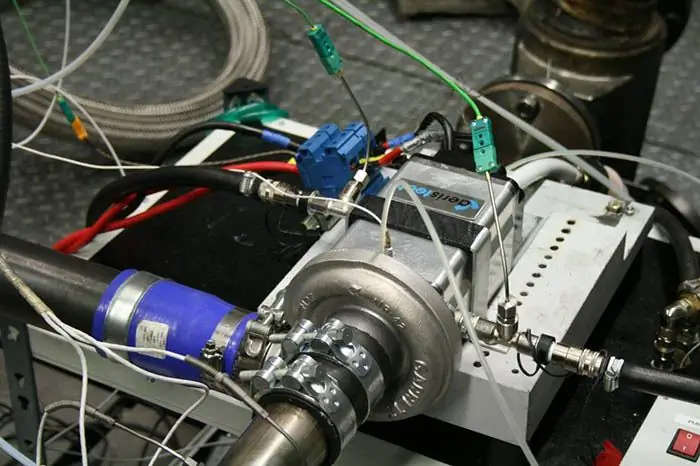

The simplest and homemade mechanisms

Early in the decade, simple, cheap machines like computer coolers, also called electric turbines, appeared on the market. They are located on the inlet and are battery operated. It is possible to use such electric turbines both on the carburetor and on the injector. According to manufacturers, they increase the flow of air entering the engine, accelerating it, which gives a performance increase of up to 15%. In this case, the parameters (revs, flow, power) are usually not indicated. It is very easy to install such electric turbines on a car with your own hands.

However, in reality, their electric motors develop up to several hundred watts, which is not enough to increase the volume of flow, since this requires about 4 kW. Therefore, such a device will become a serious obstacle at the inlet, as a result of which, on the contrary, productivity will be reduced. At best, the losses from it will be small, which will not significantly affect the dynamics.

In addition, on the Internet you can find developments on creating an electric turbine with your own hands. Unlike the cheap options mentioned above, they are built on the basis of a centrifugal compressor and a brushless motor with a power of up to 17 kW and a voltage of 50-70 V, since only such a motor is able to provide sufficient torque and speed to rotate the compressor. The motor must be equipped with a speed controller. This system does not require an intercooler - a cold intake is enough for it. The installation of an electric turbine of this type may require the replacement of a generator (for 90-100 A) and a battery (for a more capacious one with a high current output). The rotation speed of the compressor is determined by the position of the throttle. Moreover, the dependence is not linear, but exponential.

It is advisable to create such electric turbines for cars with small engines up to 1.5 liters, due to high energy consumption. Moreover, the larger the volume of the engine, the less boost pressure the supercharger can create. So, on a 0.7-liter engine, it will be 0.4-0.5 bar, on a 1.5-liter engine - 0.2-0.3 bar. In addition, such a supercharger will not be able to function for a long time at maximum performance due to heating. However, the controller can be configured to force activation.

Due to the high cost of components, it is very expensive to make such an electric turbine. Reviews indicate a measurable increase in performance.

In terms of design, these mechanisms, like the cheap options mentioned above, are electric superchargers. However, they are often erroneously referred to as electric turbines. Now on the market there are more serious branded movements that are close to homemade.

CV

Electric turbines are more responsive, productive and efficient than mechanical ones and have additional features. At the same time, on the one hand, they have a complicated design, but, on the other hand, they operate in more benign conditions.

Recommended:

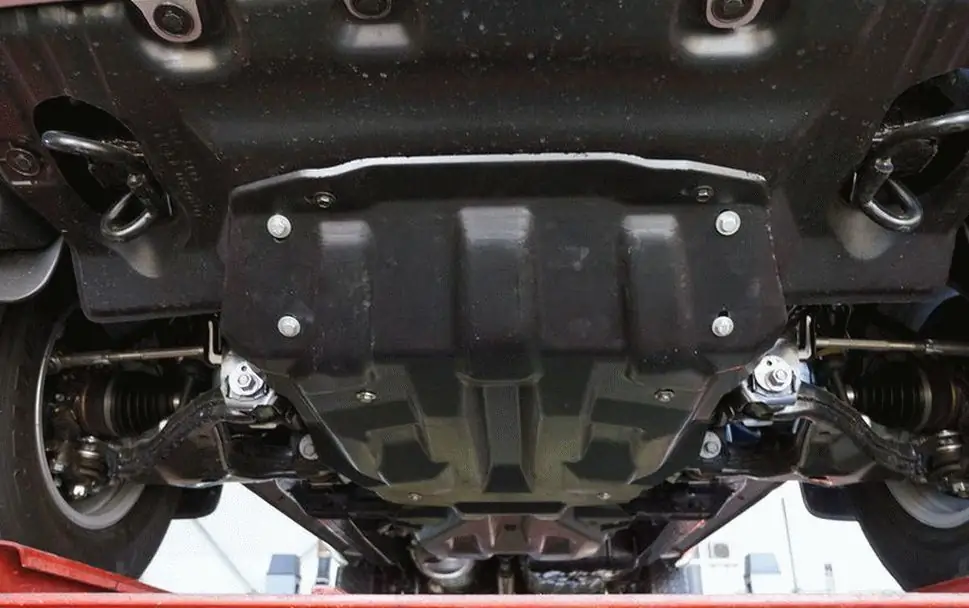

Composite crankcase protection: characteristics, principle of operation, pros and cons

The need to install crankcase protection has not been disputed by car owners for a long time. The bottom of the car covers various important units, including the transmission, transfer case, engine crankcase, chassis components and parts, and much more. Hitting any obstacles can damage them. To avoid this, crankcase protection is installed - metal or composite

CVT transmission: principle of operation, owner reviews on the pros and cons of the variator

When buying a car (especially a new one), many motorists face the question of choosing a gearbox. And if everything is more or less clear with engines (diesel or gasoline), then the choice of transmissions is simply huge. These are mechanics, automatic, tiptronic and robot. Each of them works in its own way and has its own design features

Multi-link suspension: description, principle of operation, pros and cons

Now different types of suspensions are installed on cars. There is dependent and independent. Recently, a semi-independent beam at the rear and a MacPherson strut at the front have been installed on budget-class cars. Business and premium cars have always used independent multi-link suspension. What are the pros and cons of her? How is it organized? All this and more - further in our today's article

Contract engine: how to understand what it is? Definition, characteristics, features of work, comparison, pros and cons

If the engine is out of order and it is impossible to overhaul, then the question naturally arises, where and what kind of engine to buy. A contract engine is a good alternative to a new original one and is much better than a used engine from disassembly

Air suspension: principle of operation, device, pros and cons, owner reviews. Air suspension kit for car

The article is about air suspension. The device of such systems, types, principle of operation, pros and cons, reviews, etc. are considered