2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

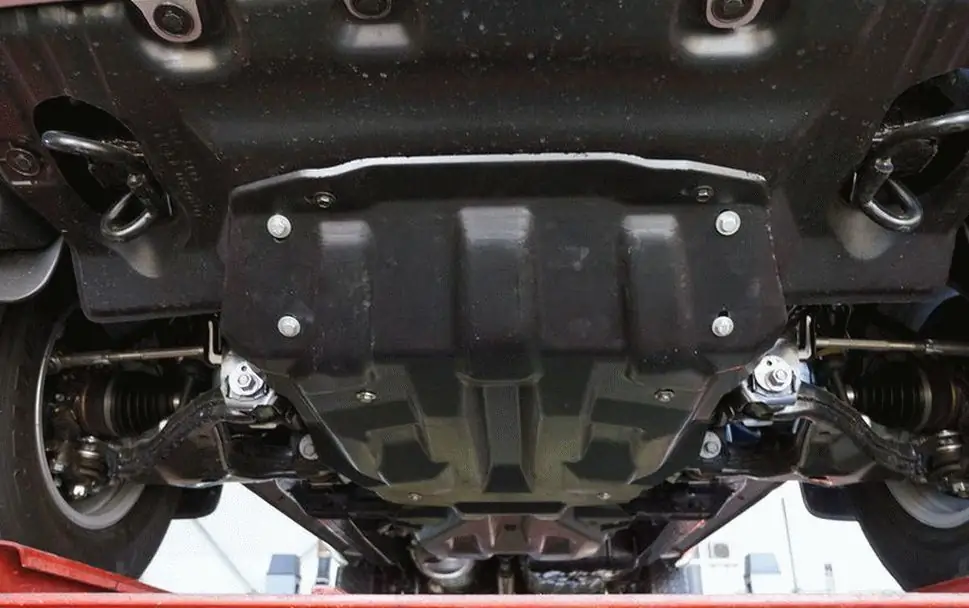

The need to install crankcase protection has not been disputed by car owners for a long time. The bottom of the car covers various important units, including the transmission, transfer case, engine crankcase, chassis components and parts, and much more. Hitting any obstacles can damage them. To avoid this, crankcase protection is installed - metal or composite.

Features of composite protections

Composite crankcase guards are made from glass fiber reinforced polymer resin material. Strength characteristics depend on these layers. For each specific protection, a certain number of layers and their thickness are selected, on which future indicators depend.

The geometric shape provides not only the strength of the protection, but also the protection of the engine compartment from moisture and dust. Due to the characteristics of the composite material -light weight, high physical and mechanical properties, resistance to corrosion and chemicals - protection has undeniable advantages:

- Providing the most effective crankcase protection thanks to a shape that closely follows the geometry of standard anthers and the layout of units that does not reduce ground clearance and does not change operating temperature.

- High bending strength and stiffness compared to metal counterparts.

- Light weight.

- Wide operating temperature range.

- Excellent vibration and sound insulation.

- Resistant to corrosion and chemicals used in road treatment.

In a frontal collision and excessive load, the composite crankcase protection is destroyed, without preventing the motor from moving down.

Composite material retains its properties in the temperature range from +120 to -60 degrees and does not emit hazardous substances when heated. The raw materials used in production have all the necessary sanitary and epidemiological certificates.

Exploitation nuances

The elasticity of the crankcase protection made of composite materials levels the loads exerted on it during impacts and collisions with obstacles. As a result, plastic deformation is completely absent, which allows you to continue operation without resorting to replacing the part. Compared to metal counterparts that require replacement in an identical situation, composite materials do not have a negative acoustic impact andretain their main characteristics without destroying aggregates and assemblies.

The difference in the cost of metal and composite protections

Composite crankcase is more expensive than metal due to the complexity of production and the uniqueness of the raw materials used. The production of models from steel and aluminum does not require expensive and complex equipment - vacuum, injection and processing. Composite protection is made from imported raw materials - fiberglass, resins, modifiers and hardeners.

Classification

There are several types of composite protections depending on the reinforcing substance used, which is part of their composition and which determines the mechanical properties:

- Kevlar (aramid fiber).

- Fiberglass.

- Carbon fiber (carbon).

Kevlar protection

Structural Kevlar is formed from short para-aramid fibers distributed within thermosetting plastics. The high mechanical strength of thermoplastics varies depending on the brand of raw materials; breaking strength of fibers - from 280 to 550 kg/mm2. At the same time, it is combined with low density - up to 1500 kg/m3. The insignificant weight of composite crankcase protections is largely determined by these indicators.

The most popular brands of para-aramid fiber are Kevlar, produced by DuPont, and Twaron, from the Japanese-Dutch company Teijin.

In 2007, Heracron-branded Kevlar appeared on the market. South Korean company Colon Industries.

Structural Kevlar has high thermal stability and chemical resistance. The strength of para-amide is 2.5 times greater than the strength of steel, which provides high strength composite crankcase protection. Unlike fiberglass, Kevlar provides excellent shock absorption.

Carbon protection

Carbon fiber, or carbon, is created from polymer resins reinforced with carbon fiber filaments. In the production of protections, carbon fiber is used quite rarely due to the fact that its cost is higher, and manufacturability is lower.

The structure of the matrix and the method of laying carbon fiber affect the properties of carbon fiber. Depending on the specific situation and need, carbon can be either rigid or flexible.

The high cost of carbon is determined by the complexity of its production technology. Layers of material are glued with high-quality and expensive resins. The equipment needed to produce carbon guards is also expensive.

CFRP is 1.5 times stronger than steel at a lower weight.

A significant disadvantage of carbon is its intolerance to point impacts: after damage, the protection cannot be restored. In case of a minor defect, you will have to change the protection completely.

Fiberglass protection

Most Toyota composite crankcases are made from fiberglass, one of the mostdemanded materials. The reinforcing material in fiberglass is fiberglass fabric, or quartz. The fiberglass matrix is made of thermoplastic and thermosetting polymers.

Fiberglass protection is one of the heaviest in its category.

The hallmark of Land Rover's fiberglass composite crankcase is its low thermal conductivity. It is resistant to mechanical damage and translucent. The strength of fiberglass is corrosion resistance, shape retention and lack of exposure to heat.

The strength of fiberglass protection is lower than that of steel, but the weight of fiberglass is also three times lower.

Steel crankcase is cheaper than fiberglass.

Advantages of composite protection

Based on the feedback on composite crankcase protection, several advantages can be distinguished:

- High strength parts. Unlike steel protections, composite ones withstand 1.5-2.5 times more load.

- Light weight of composite products. The maximum thickness of the composite protection is 12 millimeters.

- Almost complete noiselessness of this type of protection.

- Unlike metal, composite protection can be given a geometrically complex shape.

Flaws

In the same reviews of the composite crankcase protection, however, the weaknesses of the products are also noted:

- High fragility of protection, whichaffects the susceptibility of point loads.

- It's impossible to add more vents without lowering security.

- Not meeting environmental requirements - when heated, they release harmful substances.

How to choose crankcase protection

When choosing a composite crankcase, the climatic conditions of the region and driving style are primarily taken into account. An individual type of protection is suitable for almost any car, but it is important to determine the thickness of the product. This parameter depends on the purpose of protection and the materials from which it is made. Thickness mostly affects security.

The second important parameter is the weight of the product: too heavy products installed on light vehicles can adversely affect the dynamics and aerodynamic qualities.

The third parameter is the quality guaranteed by the manufacturers. Experts advise to purchase composite protection of well-known brands, and install it only in automotive services. By following the nuances of the installation process, effective protection is provided.

The last characteristic is the cost of the product. Steel models are considered the most affordable and popular options, but despite this, composite protections are more effective and profitable.

Recommended:

Electro-turbine: characteristics, principle of operation, pros and cons of work, do-it-yourself installation tips and owner reviews

Electric turbines represent the next stage in the development of turbochargers. Despite significant advantages over mechanical options, they are currently not widely used on production cars due to the high cost and complexity of the design

Twin scroll turbine: design description, principle of operation, pros and cons

Twin scroll turbines are available with double inlet and twin impeller. The principle of their operation is based on the separate supply of air to the turbine impellers, depending on the order of operation of the cylinders. This provides many advantages over single-scroll turbochargers, the main ones being better performance and responsiveness

Auto threshold protection: types, characteristics, installation, pros and cons

One of the most vulnerable places in the car are thresholds. They are most often exposed to adverse factors. And most often, rust on a car body begins precisely from the thresholds, quickly dispersing throughout the body. How can this be avoided and what kind of threshold protection exists at this time, we will tell in this article

CVT transmission: principle of operation, owner reviews on the pros and cons of the variator

When buying a car (especially a new one), many motorists face the question of choosing a gearbox. And if everything is more or less clear with engines (diesel or gasoline), then the choice of transmissions is simply huge. These are mechanics, automatic, tiptronic and robot. Each of them works in its own way and has its own design features

Multi-link suspension: description, principle of operation, pros and cons

Now different types of suspensions are installed on cars. There is dependent and independent. Recently, a semi-independent beam at the rear and a MacPherson strut at the front have been installed on budget-class cars. Business and premium cars have always used independent multi-link suspension. What are the pros and cons of her? How is it organized? All this and more - further in our today's article