2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:13

Compression is the determining factor in engine longevity. It is from this indicator that the degree of wear of various parts of the motor depends. Therefore, motorists are trying to support it in various ways. Engine compression - what is it and how is it measured? In today's article, we will try to describe this phenomenon in detail, and also learn how to measure it ourselves.

Characteristic

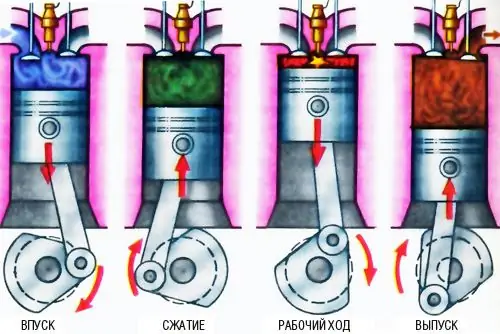

Compression is the maximum amount of air pressure in the combustion chamber that is reached when the piston is at TDC during the compression stroke. The serviceability of the motor, as well as the durability of the operation of all its mechanisms, depends on the value of this characteristic.

In simple terms, compression is an indicator of the viability of the engine, that is, the main factor in its state of he alth.

What does it affect?

Many processes depend on the level of this value, namely:

- Complete combustion of fuel in the chamber.

- Oil consumption.

- Proper operation of the cylinders. A low compression class increases the risk of engine tripping.

- Easy engine start. If the compression ratio is below normal, such an engine is very difficult to start, especially when "cold".

- The power of the power unit. It may fall over time. The lower the compression class, the lower the power of the car. Accordingly, weak characteristics of driving dynamics and acceleration follow from this.

Reasons for low compression

One of the main causes of low compression is engine overheating. With frequent boiling of the engine, scuffs form in the cylinders. They can also appear on the pistons. The latter eventually melt or burn out. Low compression (including VAZs of the "tenth" family) indicates wear of the ring partitions. As a result of all these signs, power is noticeably lost, while fuel consumption increases.

Also one of the reasons for the drop in compression is a malfunction in the timing system. In this case, there is a high risk of valve burnout. This item is no longer recoverable. Burnt valves should be replaced immediately, otherwise the power drop and increase in fuel consumption will not stop.

By the way, one of the causes of valve burnout, and, accordingly, a drop in compression, is their incorrect adjustment. If there is no necessary thermal gap between them, we can talk about serious malfunctions in the gas distribution system. In this case, the valves will not closefully. But a large gap is also fraught with its consequences. For example, this can cause insufficient opening of the valves. Because of this, less air enters the cylinder. As a result - knocks under the valve cover.

Compression also drops strongly due to burnout of the cylinder head gasket. In this situation, the exhaust gases will not exit through the muffler and exhaust manifold, but straight into the oil line or into the engine cooling system.

What else could indicate a low compression ratio? The main reason for the loss of compression is the wear of the piston rings and wear on the cylinder walls. Here, the problem is additionally accompanied by increased consumption of oil and gasoline.

Oddly enough, even an air filter can cause low compression. The fact is that a clogged element does not allow air to enter the cylinders. As a result, a very depleted mixture is formed, practically without oxygen. On some operating modes this is normal, but when the fuel is mixed in such proportions all the time, there is reason to sound the alarm.

The last reason for the reduction in the compression ratio is a crack in the head of the block. Often it happens due to engine overheating. But if you think that stockings are torn on bridges due to low compression, compression has nothing to do with it. Most likely, there was an overload in the rear of the car, no more.

What is normal engine compression?

What is it - the phenomenon of compression - we have already found out. Nowa little about numbers. But first it should be noted that this indicator is set for each engine separately, by its own manufacturing plant. The exact compression value is indicated in the instruction manual for your car. For gasoline engines, this indicator should correspond to about 9.5-10.5 atmospheres. The compression of the VAZ's of the "tenth" family is slightly higher - 11 atm. On diesel engines, the compression ratio is from 28 to 32 atmospheres. In this case, the spread between the cylinders should not exceed more than 0.5-1 atm for gasoline and 2.5-3 atm for diesel power plants. These different stocking compression classes are the result of different types of fuel ignition. If in gasoline ICEs it lights up with a spark, then in diesel engines compression occurs. Hence the different compression. This makes diesel engines more durable and wear-resistant. Practice has shown that the higher the factory compression ratio, the more powerful and economical the engine.

Specialists say that the compression value may differ, despite the stable technical condition of the internal combustion engine. This may be due to the difference in the conditions under which the measurements were made.

There are several factors that may affect the result of a compression test:

- Amount of air that enters the cylinders.

- Engine temperature.

- Crankshaft speed.

It should also be noted that viscous oil deposited on the cylinder walls also contributes to an increase in the compression ratio. This phenomenon is observed due to the sealing of the gap betweenassociated elements. Conversely, compression is reduced due to the excess amount of fuel that enters the combustion chamber.

Do not panic and be surprised if the car's mileage is 200-250 thousand kilometers, and the measurement readings are very large (for example, 10 atmospheres for a gasoline engine). The reason for this may be the accumulation of a thick layer of soot on the elements of the combustion chamber. As these deposits accumulate, the volume of the combustion chamber itself decreases, which leads to such dubious results.

When does the compression level increase?

In addition to the above factors, this figure may increase due to:

- Presence of oil in the combustion chamber.

- High engine temperature.

- Wide throttle.

Experienced motorists say that when measuring compression, you need to pay attention to only three points: engine temperature, fuel and throttle position.

How often should measurements be taken?

Drivers say that it is necessary to measure the compression ratio every 10-40 thousand kilometers and write down all the values in a notebook. Thus, you will always know what condition your engine is in at the moment. This will avoid such troubles as overheating of the motor, burnout of valves, pistons and their coking.

In what conditions should measurements be taken?

It is very important to follow the rules for measuring this indicator, because the accuracy depends on itmeasurement, and, accordingly, the further life of the "heart" of your iron horse. So, when working with a compression gauge, it is important to pay attention to the following points:

- Engine temperature. The motor must be warm before measurement, and its temperature should fluctuate between 40-60 degrees Celsius.

- Fuel supply must be turned off.

- Charged battery. Its voltage must be at least 12 and not more than 14 Volts.

- Low air humidity. It is not recommended to take measurements in rainy weather.

- Before measuring it is necessary to unscrew all the candles from the cylinders.

- Turn off the ignition.

Methods for measuring compression

Before starting work, you should make sure that this device (compression gauge) really fits the engine of your car. Stock models have a small tip, so they are difficult to use on 16-valve power plants.

Compression can be measured with both open and closed throttle. Experts recommend measuring in both cases. This will allow you to identify faults in the engine (if any) with higher accuracy.

If the measured value has increased or decreased, you can make a diagnosis - your motor is faulty and needs urgent repair. But do not forget that there is a small spread of values by cylinders, which we talked about earlier.

In order to make an accurate measurement, you need an assistant. So where do you get started? at firstit is necessary to press the compression gauge to the hole in the cylinder, that is, to where you unscrewed the candles from. At this time, the assistant turns on the starter. The latter should work for about 4-6 seconds. Further on the pressure gauge, the arrow will show the values - they must be written down.

After measuring the compression in one cylinder, move on to the next. It is checked in the same way. Such manipulations should be repeated with all cylinders. In this case, each value is recorded separately in a notebook. It is desirable that before the measurement, the battery gives a voltage of 13-13.5 volts. This will give us a reserve of starting current, since with each second of rotation of the starter, the battery charge drops to a certain level.

After completion of work, it is necessary to install the candles back and re-check the voltage in the battery. Recharge it with a few volts if necessary.

Helpful advice

To more accurately determine the current state of the engine, it is necessary not only to focus on measured compression indicators, but also on a number of other characteristics. This can be the level of vibrations, noise, fluctuations in power, engine idling, oil and fuel consumption.

Conclusion

So, we found out what compression should be and how it can be measured. The indicators on the device allow you to accurately determine the internal condition of the motor, its remaining life and current malfunctions. And if you find that you have no compression, such an engine should be subjected to a more detailed inspection and repair. ATotherwise, after a couple of thousand kilometers, it will destroy itself, and no major overhaul will save it.

Recommended:

Engine water hammer: causes and consequences. How to avoid engine water hammer

The internal combustion engine is the heart of the car. The service life of the unit depends on the conditions under which it is used. But there are breakdowns that have nothing to do with the current state of the motor. This article will discuss what an engine water hammer is, why it happens and how to avoid this kind of breakdown. But first things first

Understood. What is the compression ratio?

The article describes such an engine characteristic as the compression ratio. Examples of its increase are given, as well as other trifles of using this indicator of the car

What is engine life? What is the engine life of a diesel engine?

Choosing another car, many people are interested in equipment, multimedia system, comfort. The motor resource of the engine is also an important parameter when choosing. What it is? The concept as a whole determines the operating time of the unit until the first overhaul in its life. Often the figure depends on how quickly the crankshaft wears out. But it is written in reference books and encyclopedias

Compression ratio and octane number of gasoline

Very often, novice drivers wonder what kind of gasoline is better to fill in a car. At the moment, there are several varieties of fuel, with different octane ratings. Which type is better to use so as not to "sentence" the motor? What is the octane number and compression ratio of an engine? Let's try to understand our today's article

Compression and compression ratio: difference, principle of operation, similarities and differences

Does every vehicle owner clearly understand the difference between compression and compression ratio? Meanwhile, this is by no means the same thing, as some motorists (often beginners) believe, due to little experience. This should be understood at least in order to be able to fix a slight malfunction on your own, without the help of a qualified specialist. In addition, it will be the accumulation of personal experience, which in any case will not hurt