2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

Any car has attachments. These are nodes and mechanisms, without which its work is not possible. Attachments include a starter, power steering pump, air conditioning compressor, intake and exhaust manifold, clutch. But this list also includes a car generator. It is he who allows you to maintain a stable voltage in the on-board network. Few people know the device of a car generator and its principle of operation. But this information will be useful for every driver. Well, let's look at how this hinged element works and works.

Characteristic

A generator is an electric motor that converts mechanical energy into current.

This element is used to power electrical equipment when the internal combustion engine is running, as well as to charge the car battery. All modern cars use an automotive alternator.

Where is it

Often this mechanism is located in front of the engine. It works from the crankshaft by means of a belt (river or toothed type). Typically, automakers place the generator at the highest point relative to the engine. However, there are models where the mechanism is attached almost in the area of \u200b\u200bthe engine crankcase. Why is it important to position the mechanism at the highest possible point? The fact is that the car generator is very afraid of water. Even a small amount of moisture can damage it. Therefore, manufacturers are trying to exclude the possibility of water and other liquids penetrating the surface of this mechanism. The higher this element is located, the safer it is for it.

Device

The generator design includes:

- Stator winding.

- Front cover.

- Excitation winding.

- Brush knot.

- Back cover.

- Slip rings.

- Pole halves.

- Rectifier unit.

- Drive pulley.

- Fan impeller.

Also note that this node can have a different layout:

- Traditional.

- Compact.

The differences are in the structure of the fan, rectifier assembly and drive pulley. Otherwise, the device and operation of the car generator are identical. Both the traditional and the compact mechanism consist of a rotor, a rectifier unit, a brush assembly, a voltage regulator and a stator. What are all these components for?consider further.

Rotor

This mechanism is used to create a magnetic field in the generator. An excitation winding is provided on the rotor shaft. The latter is placed in special pole plates, each of which has six protrusions. In addition, a contact ring is located on the shaft. It serves to power the excitation winding. Usually rings are made of copper (less often - of brass). The excitation winding leads are soldered to these elements.

Also, there is one or two fan impellers on the rotor shaft. They provide winding cooling during generator operation. The rotating mechanism of the rotor is two ball bearings, maintenance free.

Stator

Its function is to create alternating current. The car generator is necessarily equipped with this element. The stator is structurally integrated with the winding and the core. The latter is a set of several plates. In 36 winding grooves there are three more windings, which form a three-phase connection. Manufacturers use two types of windings:

- Wave.

- Loopback.

The connection itself is carried out using different technologies:

- Scheme "triangle". In this case, the ends of the winding are connected in series.

- Star pattern. Here the ends of the winding are connected at a single point.

Case

It contains most of the components of the generator. The case consists of two covers: rear and front. The first is on the side of the slip rings, the second is on the side of the drive pulley.

These parts are tied together with long bolts. The lids themselves are made from non-magnetic aluminum alloy. The case also includes ventilation windows and two mounting feet.

Brushes and rectifier unit

The brush assembly is used to transfer current from the excitation winding to slip rings. How is this node organized? It consists of two graphite brushes with springs. The whole structure is integrated with the voltage regulator of the car alternator.

Now about the rectifier unit. It is necessary to convert the sinusoidal voltage into direct current of the on-board network. This block consists of plates. They perform the function of a heat sink, and diodes are also mounted on them. In total, there are six semiconductor diodes in the block. There are two such elements for each phase. One is connected to the positive, and the second - to the negative terminal of the car alternator. Usually the connection is made by soldering or welding at the mounting sites.

Voltage regulator

We continue to study the device of a car generator. In the design of the mechanism there is always a voltage regulator (in the slang of motorists - “chocolate”). This item can have:

- Hybrid connection. In this case, all radio elements and electric drives are used in a circuit with microelectronic thick-film elements.

- Integral. Here, all elements of the regulator, with the exception of the output stage, are performed by thin-film microelectronictechnology.

The main task of the "chocolate" is to stabilize the voltage, which can vary with changes in the number of revolutions of the crankshaft and the total load of the on-board network.

This correction is carried out automatically due to the effect on the excitation winding current. The regulator changes the duration and frequency of the current pulses. Modern generators have regulators with thermal compensation. Thus, the lower the temperature of the battery, the more voltage is applied to its charge.

Generator drive

On all vehicles, this equipment is driven by the crankshaft via a belt. The latter can be wedge or polywedge type. The scope of the first is significantly limited by the diameter of the driven pulley. The number of revolutions of the rotor when the engine is running is usually two or three times the speed of the crankshaft.

Often, cars use a V-ribbed belt. It is more versatile, because with a small diameter of the driven pulley, the belt allows you to realize a larger gear ratio. The tension of the drive element is adjusted using a special roller.

The principle of operation of a car generator

How does this equipment work? Its principle of operation is as follows. When the key is turned, current from the battery flows through the brush assembly and rings to the excitation winding. A magnetic field is induced in the winding. When the crankshaft of the internal combustion engine rotates, the generator rotor also works at the same time. The magnetic field of the latter permeates the windingstator. An alternating voltage is generated at the terminals. At a certain speed, the generator begins to self-excite. Thus, the winding is powered by the generator itself.

The rectifier unit starts to convert this voltage into direct current. With a change in the load on the engine, the so-called. "chocolate". The regulator corrects the frequency of turning on the generator winding. As the speed increases, the switch-on time decreases. Conversely, when the load drops, the frequency increases.

Brushless generator

Some cars have a brushless mechanism. In its design, it has a rotor with pressed transformer iron plates. The winding is placed on the stator. And the electromotive force is formed by correcting the magnetic conductivity of the gap between the stator and the rotor.

Car alternator specifications

The main parameters of this mechanism include:

- Rated current. This is the peak output current at a speed of six thousand revolutions per minute.

- Rated voltage. Depending on the type of vehicle electrical system, this parameter is 12 or 24 V. Most cars and SUVs use a 12-volt circuit.

- Power. A car alternator can be either 60 or 120 amp. It all depends on the type of car and the size of the engine itself. If we talk about most cars, they often use 80-ampgenerator.

Diagnosis

Is it possible to check the condition of a car generator with your own hands? Experts say that it is possible to diagnose an element in garage conditions using a conventional multimeter. But before that, you need to check the connection of the car generator, and also make sure that all connections are working. Open the hood of the car and find the drive belt. It should be taut with such a force that it will bend 1-1.5 centimeters deep from the pressure of the thumb. If we talk about exact values, this deflection is measured with a force of 10 kgf.

At the first stage, the voltage regulator is checked. To do this, we transfer the multimeter to the voltmeter mode. We warm up the engine at medium speed with the headlights on for ten minutes. Next, we measure the voltage at the output of the generator mass and at its plus. The nominal value is from 13.5 to 14.6 V. If the figure is less or more, then the regulator is not doing its job and needs to be replaced.

Next, we proceed to the diagnostics of the diode bridge. We turn on the device in the mode of measuring alternating current. We connect the probes to the clamp "30" and to the mass of the generator. The voltage should be no more than 0.5 V. Otherwise, the diode bridge does not work correctly. To check the breakdown to ground, turn off the generator and remove the generator cord, which is suitable for the positive 30th terminal. Next, we connect the multimeter with probes to the disconnected generator drive and terminal. The discharge current should not exceed 0.5 mA. If hemore, there was a breakdown of the insulation of the winding or the diodes themselves.

Checking the recoil current

Please note: the recoil current is measured using a probe, which is an addition to the multimeter. This element is a kind of clamp with which the wires are covered, and the current strength is measured. So, how do we test the generator? To do this, we cover the wire leading to the clamp on the 30th terminal with a probe. Start the engine and keep it at high speed. We turn on the light, stove and other electrical appliances. Next, we alternately measure each consumer individually. The value of the measurement should not exceed the sum of the readings of each consumer. The maximum discrepancy is 5 amps down.

It will not be superfluous to check the excitation current of the generator. To do this, start the engine and let it run for five minutes at high speeds. Next, we place a measuring probe around the wire with terminal 67. The readings will be equal to the strength of the excitation current. On a working generator, this figure is about three to seven amperes.

To check the excitation winding, you need to dismantle the "chocolate" and the brush holder. We transfer the device to the ohmmeter mode and apply the probes to the slip rings. The resistance level should be between five and ten ohms. Then we connect one probe to the stator. We hold the second on any of the slip rings. The device should show an infinitely large resistance. If this is not the case, then the winding is shorting to ground.

Conclusion

So we figured outwhat is a car generator and how to check it. As you can see, diagnostics can be done by hand. However, in order to understand this issue, you need to at least superficially know the device and the algorithm of the element.

Recommended:

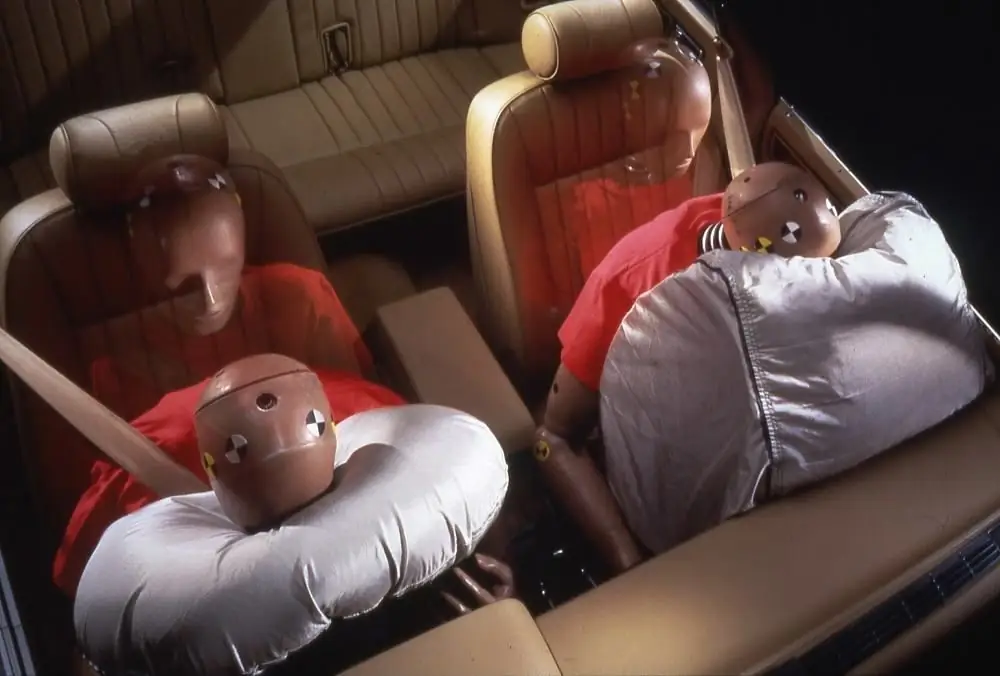

How airbags work in a car: device and principle of operation

Modern cars are equipped with many protective systems, including airbags. They allow you to avoid serious consequences for the driver and passengers (depending on the configuration). Moreover, their number varies from 2 to 7 pieces, but there are models where there are 8, 9, or even 10 of them. But how does an airbag work? This will be of interest to many motorists, especially inquisitive individuals who want to be well versed in their car

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

Planetary gearbox: device, principle of operation, operation and repair

Planetary gears are among the most complex gear boxes. With a small size, the design is characterized by high functionality, which explains its widespread use in technological machines, bicycles and caterpillar vehicles. To date, the planetary gearbox has several design versions, but the basic principles of operation of its modifications remain the same

Carburetor and injector: difference, similarities, advantages and disadvantages of carburetor and injection engines, principle of operation and expert reviews

For more than a hundred years, the car has firmly established itself in our lives. During this time, managed to become a familiar, everyday means of transportation. Let's see what the difference is between a carburetor and an injector, what advantages and disadvantages they have