2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Any manual transmission has an input shaft bearing in its device. The input shaft is one of the leading elements in the transmission. It is necessary to transmit torque from the clutch discs to the driven and intermediate shaft. The primary element rotates around its axis due to bearings. The latter fix the shaft, center it, and also protect the part from vibrations. Also, these elements are one of the important links in the manual transmission system.

Device

Needle bearings are predominantly used to support the shaft. The use of thin and long rollers makes it possible to minimize the thickness of the ring while maintaining high load resistance.

Mounting parts has its own characteristics. During operation, the element develops its installation site. Due to the growing backlash and vibrations, the part is gradually destroyed, and then it is necessary to replace it.

Failure symptoms

Signs of failure of this element are strongly related to the place of installation. Bearingthe input shaft of the gearbox is mounted on the input shaft, and behind it is the oil seal. In various transmission models, the bearing itself can work as an oil seal. So, paired with a clutch release, this part experiences almost the entire load from the car engine. To find the problematic bearing, you need to dismantle the transmission. The symptoms of failure of this element are similar to how any other bearings become unusable. In case of serious breakdowns, characteristic sounds resembling a howl are heard from the checkpoint. This sound can be heard when the clutch is released and the vehicle is stationary. But also the input shaft bearing can whistle while driving. It is very rare to hear characteristic knocks - they indicate the complete destruction of the node.

There are also problems with engaging or not disengaging the clutch. The reasons for this operation of the gearbox are in this bearing. A malfunction often occurs if the part is jammed. In difficult situations, it may be necessary to replace the input shaft. Often whistling and hum are heard in the absence of lubricants in the bearing. This issue can be resolved by lubricating the part. But first, it must be removed from the gearbox. The transmission will make a howl if the bearing has chips and cracks, or one or two rollers are destroyed. If characteristic knocks are heard, then this indicates a complete failure of the part. The knock will come out in any gear. If a worn or damaged part is not replaced in time, then the element can seriously “weld” to the shaft. As a result, you will have tochange the input shaft bearing and the shaft itself.

Causes of breakdowns

The wear and tear of an element can be influenced by many different factors. Often the fault is the poor quality of parts. When purchasing a product, you should not give preference to the cheapest options, but you should purchase a quality product. It is necessary to carefully inspect the assembly and make sure that it is reliable and made of strong materials. Also one of the possible reasons is the manner of driving. If the driver uses too aggressive style, literally tearing out the shift lever, then this does not add life to the bearing, but seriously reduces the life.

The conditions in which the car is operated are also important. If the car is constantly stored in the garage, if there are no overloads, then all this will have the best effect on the resource of each node. And finally, the most popular reason why the VAZ input shaft bearing fails is ignoring the maintenance of the mechanisms and components of the car. Owners of inexpensive cars who use them for work, as well as novice drivers who are just learning, can ignore maintenance.

How to replace

Replacing the input shaft bearing can be done by yourself.

You don't need any special skills to do this. Also, you do not need special tools to work. You don't even need to disassemble to replace.box. But the dismantling of the gearbox is still necessary.

How to remove the transmission?

To remove the box, you need an inspection hole or a lift. Also, for work you need a standard set of tools - a crank, heads, wrenches and a mount. The dismantling process is carried out in several stages:

- First of all, disconnect the terminal on the battery. Then the neutral gear is turned on, the parking brake is turned off. Raise and withdraw the rear axle. Next, unscrew the bolts holding the cardan and the gearbox flange. After that, you can disconnect the driveshaft.

- Then unscrew the bolts and dismantle the intake pipe of the exhaust manifold, disconnect the oxygen sensor, remove the starter. Next, in the car, you need to dismantle the console and gear knob.

- After that, the box protection is removed, the clamps that connect the exhaust pipe to the catalyst are unscrewed. After that, you can dismantle the clutch slave cylinder. Next, unscrew the speedometer cable, remove the boot and the reverse gear cable. Now you can get the cardan shaft. Then the traverses are unscrewed (at the same time it is necessary to hold the box so that it does not fall). Finally, you can unscrew and remove the gearbox assembly.

Where is the bearing, how to dismantle it?

On domestic vehicles, the input shaft bearing is located on the secondary shaft, directly behind the oil seal. When the gearbox is already completely removed from the car, they take out the bell, as well as the retaining rings. There is no need to disassemble the assembly further.

Forin order to replace the part, you need to hook the bearing on its annular groove with a screwdriver. Next, the input shaft is pushed forward, using the bearing as a support. Then slowly pull the bearing off the shaft by tapping it with a hammer. You shouldn't hurry. Replacing the VAZ input shaft bearing can take from several minutes to one hour.

How to install a new element on the shaft?

A new part on the input shaft can be installed using press-fit technology. The bearing is generously lubricated with engine oil and then pressed in with a small hammer.

It is important that the tool is not only small, but also not heavy. With a hammer, you need to gently and evenly hit the inner ring of the part. The shaft is pulled forward. After pressing, it is recommended to make sure that the part is working properly. A serviceable bearing rotates easily and quietly, without noise. After the replacement of the input shaft bearing (including VAZ) is completed, the gearbox is installed in its rightful place. All assembly work should be done in reverse order.

Helpful tips

If the bearing is completely free of oil, but there is no damage on its surface, then the replacement can not be performed, but lubricated and installed back. This is done if, for some reason, the necessary spare part is not on hand. Lubricate the bearing of the input shaft of the gearbox (including VAZ) in two ways. The first option involves boiling the part in lithol. The best thingcarry out this operation in a water bath. But there is a safer option - lubrication by injection. To do this, lithol is drawn into a syringe and grease is filled into the bearing. But keep in mind that such a process requires more time.

Recommended:

Connecting rod bearing: device, purpose, specifications, features of operation and repair

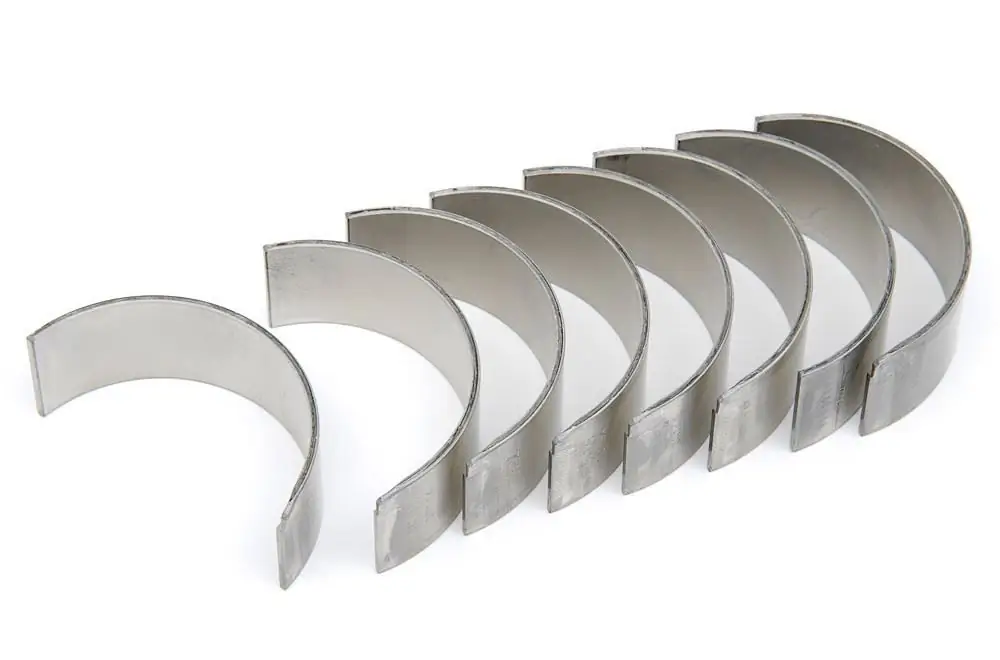

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

What is a connecting rod bearing? Main and connecting rod bearings

The crankshaft of the engine is a body of rotation. He rotates in special beds. Plain bearings are used to support it and facilitate rotation. They are made of metal with a special anti-friction coating in the form of a half ring with precise geometry. The connecting rod bearing works like a plain bearing for the connecting rod, which pushes the crankshaft. Let's take a closer look at these details

Shaft support - what is it?

The layout of the guide shaft and support bearings is a very cheap and profitable way of linear movement. In the production of CNC machines, it is very often used. Also used for the manufacture of modern 3D printers, milling systems and even plasma cutting machines

What is a steering shaft cross and how does it work?

The steering shaft crosspiece is one of the main components of the driveshaft of each car. This mechanism performs the function of transmitting torque from the box to the drive axle (usually rear) at a constantly changing angle during rotation. Today we will look at how the steering shaft cross is arranged, what it is made of and how it works

What is a flexible shaft

Any flexible shaft has a high torsional stiffness and a much lower bending stiffness. The main purpose is to transmit rotation and torque to parts that change their position during operation. Flexible wire shaft can easily bend in all directions