2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

At present, despite the rapid development of technology, it is not possible to create a completely sealed pair of friction parts - a cylinder and a piston ring. Therefore, combustion products accumulate in the internal combustion engine over time during operation.

In the sump crankcase gases pass through the piston rings, which do not fit snugly against the cylinders. The result is poorer heat dissipation, reduced fluid life and excessive pressure on all block seals. The crankcase ventilation system prevents excessive crankcase pressure.

Device Development

In the beginning, the mechanism looked like this: a tube was simply removed from the crankcase, releasing gases into the atmospheric air and polluting it. But the norms for the emission of gases from vehicles have been seriously tightened. Therefore, the crankcase ventilation system was forced to be developed by manufacturers.

The principle of operation of the mechanism

As the system is currently known, gases are not justare released into the atmosphere. They are sent to the engine through a tube removed from the crankcase, the other end of which is connected to the intake manifold. From there, the gases are directed to the combustion chamber. At the time of the flash, some of them burn out, and the other part is ejected through the exhaust mechanism. Only a small fraction of these gases enters the crankcase again. So the process goes on without interruption.

Types of Crankcase Recirculation System

Two types of system are known:

- open;

- closed.

In the first case, as described at the beginning of the article, gases are simply discharged into the atmosphere. In the second, they are sucked into the inlet pipeline. The closed crankcase ventilation system: VAZ and Lada, BMW and Mercedes, Japanese and Americans are mainly used at the present time.

Besides this, closed systems come with variable or constant flow. The first type is more accurately able to regulate crankcase recirculation. It varies depending on the amount of incoming gases.

Device

At the top is the oil separator of the crankcase ventilation system, and inside it is an oil deflector. Its task is to release gases from oil particles. The oil separator of the crankcase ventilation system has an outlet with a pipeline. During normal operation of the motor, a certain vacuum must constantly occur in the crankcase. The valve can operate in three ways.

Forced systemcrankcase ventilation: valve

Let's briefly consider all three of these options.

1. A low pressure of 500 to 700 mbar is formed behind the throttle. The crankcase ventilation system does not withstand this mode. And the piston, under vacuum, closes the valve.

2. If the throttle is fully open, then the pressure there is the same as atmospheric or even higher. When reaching 500-700 mbar, the piston closes the valve for the passage of gases.3. The middle position provides normal piston pressure.

If the operation of the valve raises questions, then its serviceability is easy to check. To do this, at idle, a sheet of paper is placed on the neck where the oil is poured. If it moves up and down with the diaphragm movement, the valve is good.

Normal operation can be checked in another way. At idle, remove the ventilation hose and close it with your finger: suction should be felt.

Reducing valve

If the engine operates at high speeds, a pressure appears in the intake manifold that is equal to or greater than atmospheric pressure. In this case, more gases enter the crankcase. If there is a turbocharger in the intake, the vacuum will be too high and should be balanced.

For this, a pressure reducing valve is provided, which operates in the intake manifold when the damper opens. The mechanism, consisting of a membrane and a spring, is inserted into a plastic case, which has inlet and outlet fittings.

Reducing valve operation

Under normal vacuum, the spring is not loaded. At the same time, the membrane is raised and gases are passed freely.

When the pressure is reduced, the diaphragm lowers and closes the outlet, overcoming the action of the spring. Then the gases begin to move through a bypass - a channel with a calibrated hole.

Unfortunately, while acting positively on the one hand, the crankcase ventilation system creates a problem on the other. Coming out of the sump, gases also capture lubricant particles, thus polluting the intake system. In addition, they settle on the surfaces of the outlet channels and the parts of the recirculation valve. This leads to a narrowing of the channels and can cause malfunctions in the injection. If the diaphragm jams, then the oil consumption will increase. Then you have to change the valve.

You also need to remember about another important detail and change the crankcase ventilation system hose in time - this is usually done together with recirculation valves. Otherwise, cracks and tears will form on it.

To prevent costly repairs, it is necessary to pay attention to the appearance of spots on the engine seals, increased consumption of fuel and lubricants and unstable operation of the motor. If you drive to the service center in time, the problem can be solved in the bud, before it has time to cause significant damage to the unit.

Recommended:

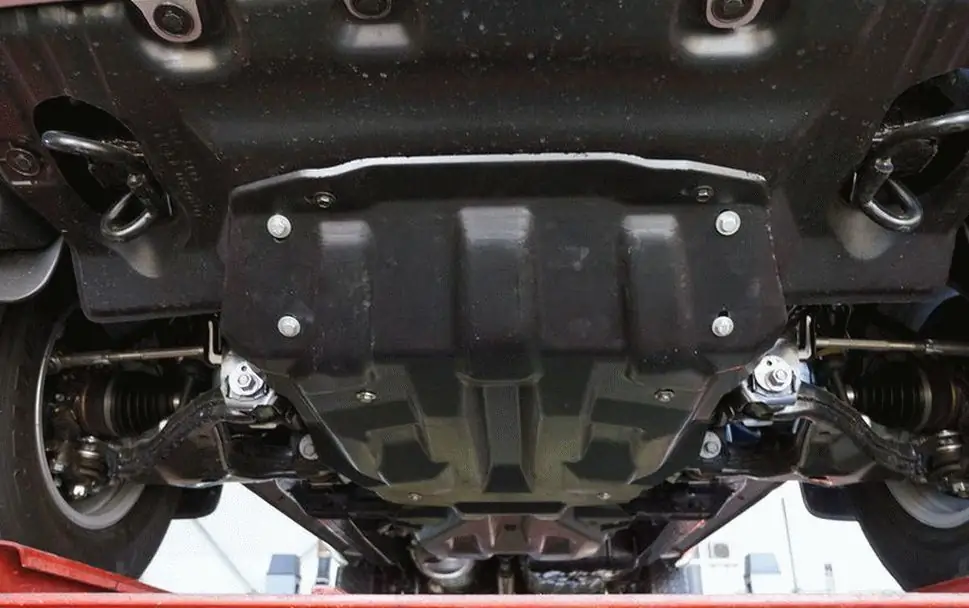

Composite crankcase protection: characteristics, principle of operation, pros and cons

The need to install crankcase protection has not been disputed by car owners for a long time. The bottom of the car covers various important units, including the transmission, transfer case, engine crankcase, chassis components and parts, and much more. Hitting any obstacles can damage them. To avoid this, crankcase protection is installed - metal or composite

ABS system. Anti-blocking system: purpose, device, principle of operation. Bleeding brakes with ABS

Not always an inexperienced driver manages to cope with the car and quickly reduce the speed. You can prevent skidding and blocking of the wheels by intermittently applying the brake. There is also an ABS system, which is designed to prevent dangerous situations while driving. It improves the quality of grip with the roadway and maintains the controllability of the car, regardless of the type of surface

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

Crankcase ventilation valve: types, device, principle of operation

During engine operation, not only exhaust gases are released. Few people know about crankcases. Vapors of fuel, oil and water accumulate in the lower part of the engine. Their accumulation worsens and destabilizes the operation of the motor. To remove these substances, a crankcase ventilation valve is provided in the design of the car. Tuareg is also equipped with them. What is this element and how is it arranged? You will read the answers to these and many other questions in our today's article