2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Modern cars are equipped with many different control systems. They are divided according to their functional purpose. Distinguish control systems for the operation of the engine, chassis, comfort and safety of the driver. Dynamic performance is important for every motorist. If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it.

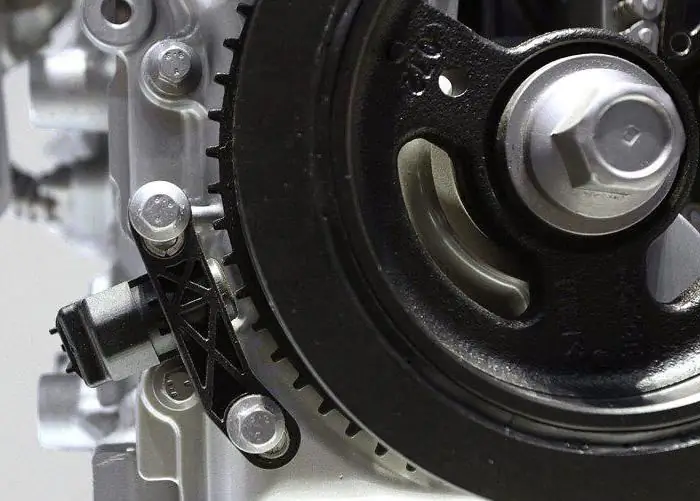

Crankshaft sensor - device and principle of operation

It must be said that this sensor is the only one without which the car will not be able to work normally. The crankshaft position sensor is also called the timing mechanism. It is he who allows the ECU to synchronize work with the timing of the engine. The device helps generate signals for clock, cyclic, as well as angular control of the injection of the fuel mixture and the ignition system.

The principle of operation of this sensor is not as complicated as it canto appear. It lies in the creation of an inductive signal. But there are other types of systems. These are the Hall sensor and optical systems. At the moment when the teeth on the crankshaft pulley pass near the sensor core, pulses with alternating voltage are formed. In other words, this is an electromagnetic device that synchronizes the operation of the injectors, as well as the ignition systems in the injection system. This is the main link, without which the operation of the motor will be simply impossible. The sensor works in tandem with a synchronization disk. Due to this, angular impulses are formed. The disc has 60 teeth, in which 2 are missing. This contributes to the generation of impulses. The angle of one such tooth with the distance to the next is 6 degrees from the position of the crankshaft. The beginning of the 20th tooth after the cut point completely coincides with the top dead center for the first or fourth cylinder.

The sensor provides for a gap between the teeth of the disk and the end part, and the sensitive element is a winding of copper wire on an insulated coil with a core inside.

Where is the sensor located?

This device is made in a plastic case. You can find it on a special bracket near the synchronization disk or next to the generator pulley. The car uses a large number of different sensors - DPKV can be recognized by a long cable with a connector.

Causes of failure of the crankshaft position sensor

This sensor will not malfunction by itself. Sensor eitherworking or not working at all. If it fails, it is an irreversible process. There can be several reasons for this part to fail. Most often, the malfunction is caused by constant loads when working at high temperatures, high humidity, and mechanical stress. Many do not know how to check the he alth of the crankshaft sensor, and visit a service station with this problem. In fact, everything is very simple. There are affordable methods that you can use at home and at the same time completely free.

Signs of problems

The most common type of sensor failure is partial or complete wear of the wiring. How to check the crankshaft sensor? This can be done using special scanners. Today they have become more accessible. To understand that the device is out of order, a burning light on the dashboard will help - “Check the engine”. But this is only true for new cars.

But the owner himself will have to deal with old cars. With a failed DPKV, the driver will encounter a lack of idling - the engine will stall. The motor will show unstable operation at idle. Also, a car where there is a problem with this sensor will stall when driving. And another sign is detonation under load. If at least one of these signs is observed, most likely the crankshaft sensor has broken. How to check it? There are several options here. Use the services of professional diagnosticians in the service station or perform testingon one's own. There are several ways to do this. The verification procedure itself does not cause difficulties, but there is one unpleasant moment - the sensor is very inconveniently installed, and in order to get to it, you need to use special tricks.

Ways to check DPKV

There are three options for checking the crankshaft position sensor. In each case, different, but at the same time accessible to everyone, devices will be used. The easiest way involves an ohmmeter, but a tester or multimeter will do. The second requires the use of several devices. At the service station, these sensors are checked with an oscilloscope.

The first step is to dismantle the sensor. It is first recommended to mark its position - then you need to install it back strictly to this place. Here is the crankshaft sensor removed. How to check it? First visually.

Visual diagnostics

Case, contacts, core, terminal block must not have any damage.

When assessing the condition, thoroughly clean the device from dirt. This is especially true for contacts. Cleaning can be done with a rag soaked in gasoline or alcohol. There is no fundamental difference how to check the crankshaft sensor. "GAZelle" or any other car in this regard are similar. When dismantling, the distance between the core and the synchronization disk is checked - it ranges from 0.6 to 1.5 mm. The gap can be adjusted using the appropriate washers. If the examination fails to revealdamage, it is necessary to apply other methods, how to check the crankshaft sensor. These methods will tell you more accurately whether the device is working or not.

Checking DPKV with an ohmmeter

This is the easiest method. It is available to everyone. If an ohmmeter is hard to find, a regular multimeter will do. They check the resistance on the sensor coil. The performance of the sensor depends on whether the coil is working.

In good condition, the resistance will be between 550 and 750 ohms. For complete certainty, before checking the crankshaft sensor with a tester, it is better to study the manual for the machine - the manufacturer indicates the exact parameters there. If the readings match, then the sensor is OK. If not, then it needs to be replaced. This is the easiest way. But the disadvantage is that there is no full guarantee of the correctness of the diagnosis. Experts recommend applying a more global check.

Diagnosis with megohmmeter

There is a suspicion that the crankshaft sensor is faulty. How to check it more accurately? There is a good way. During the operation, measurements of the main parameters of the device will be performed. For diagnostics, you need a multimeter, a megohmmeter, an inductance meter and a transformer. Resistance is measured in the same way as in the first case. As for the inductance, it is measured using a special device - the indicators should be from 200 to 400 MHz. It's okay if the disk gets a little magnetized. You can demagnetize it using a network transformer. Insulation resistance checkmegaohmmeter. Under a voltage of 500 V, this parameter should not exceed 20 MΩ. Based on the numbers received, you can then draw conclusions about whether the sensor needs to be replaced or is it working.

A more efficient way to check the crankshaft position sensor has not yet been invented. It has been used by experienced motorists for many years, it is possible to check it at home.

Summarize

There is another diagnostic option - this is a test with an oscilloscope. This method is used in the service station. The problem is that, in addition to the oscilloscope, you also need special software, which is sometimes impossible at home. Therefore, it is better to measure the key parameters of the sensor and compare them with the passport values. Even novice motorists will not have difficulty with how to check the crankshaft sensor (including Opel Astra) in these ways. These diagnostic methods have shown their effectiveness more than once.

Recommended:

Why is the Check Engine light on? Why does the check engine light come on?

In the age of modern technology, the technical characteristics of a car provide for the presence of a large number of electronics. Cars are literally stuffed with it. Some motorists do not even understand why it is needed or why this or that light is on. In our article we will talk about a small red light bulb called Check Engine. What is it and why does the "Check" light up, let's take a closer look

Crankshaft sensor: why does it break and how to replace it?

Probably, every motorist got into such a situation when one fine day, after turning the ignition key, his "iron friend" completely refuses to start. Oddly enough, but the reason for this can be not only a planted battery or a burnt starter, but also a crankshaft sensor

How to check if the air flow sensor is working?

A lot depends on how well the air flow sensor works, incl. vehicle power and fuel consumption. How to check the performance of the device?

How to check the temperature sensor: description, step-by-step instructions and recommendations

The operation of the motor and other vehicle systems is controlled by certain sensors. They are located in different parts of the system. How to check the temperature sensor of the coolant, air and other control devices will be discussed in the article

How does the crankshaft position sensor interact with other car parts?

Each car, regardless of the year of manufacture and brand, is certainly equipped with such a detail as a crankshaft position sensor, which ensures the smooth and uniform operation of the engine