2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Crankcase is called the entire lower part of the engine block. The engine oil pan is a removable element molded from sheet metal or cast aluminum. The part is the lower part of the motor.

Design and purpose

The main function of the sump for modern models of power units is the accumulation and storage of oil that drains from engine parts. Also, as already noted, the engine oil pan protects the internal elements from the aggressive influence of the environment. Even at the bottom of the pallet, metal particles are collected, which are formed due to wear of friction parts. In addition to these tasks, the part helps to cool engine oils and protects the lubricant from splashing.

Most often this part is produced by stamping, and soft and elastic grades of steel are well suited as materials. Such a material was not chosen by chance - the finished part will not burst if damaged, but only deformed. The tray is made in the form of a shallow bath. In its upper part there is a plane with mounting holes. Depending on the type of power unit and its levelmanufacturability, the engine oil pan may have a different, often more complex shape. This is done to avoid contact with transmission or suspension parts as much as possible.

If the motor is forced, then the pan must be made of aluminum alloys. In such parts, ribs are necessarily implemented that contribute to the cooling of the oil. When changing lubricant to drain the used product, many vehicles have a plug. The engine crankcase sump has a threaded drain hole - if the plug is unscrewed, the used grease can be conveniently drained. However, the main function of this part is not to protect the connecting rod and piston group and the crankshaft, but to accumulate and store lubricant. And at the bottom of the container-pallet, chips are accumulated, which are formed due to the wear of rubbing pairs. It is so small that it freely passes through the oil filter, and in this case the sump acts as a passive filter.

Typical breakdowns

This part is so simple that it takes a lot of effort to disable it. The only thing that can happen is damage due to hitting various obstacles. In this case, reinforcement, stone, sudden stump can simply deform or break through the element. Most often, the repair of the engine oil pan is necessary for cars with a front-wheel drive type and a longitudinal or transverse engine.

What happens if you do not repair or change the pallet?

So, if the element is damaged, then this is definitelyaffect the operation of the power unit. Let's take a look at some damage. If there is a deep deformation of one of the planes without a hole on the motor with an oil receiver, and the pan itself is made of aluminum alloy or plastic, then in this situation there is a risk that the oil receiver tube will be above the level of the lubricating fluid. Often, with such damage, these parts break off altogether.

If the oil does not leak out, but the deformation is deep enough, you need to add the right amount of oil and try to start the engine. In the case of minor deformations and the absence of a breakdown, the oil receiver may not break off, however, the gap between the tube and the bottom of the sump will greatly decrease - this may be enough to operate the engine under low loads. It is important to bear in mind that if the sump is damaged, at any time the engine may experience "oil starvation" during sharp accelerations and increasing speeds. All this will not have the best effect on all nodes. The most common consequence of oil starvation is the seizing of the upper connecting rod bearing, which entails the seizure of the entire engine. Also, the liner can turn during operation. In extreme cases, the connecting rod will break, resulting in damage to the cylinder block.

How to repair oil pan

If the engine oil pan is broken, the first thing to do is to immediately turn off the engine. If this is not done, then due to the rapid decrease in the level of the lubricating fluid, its supply to the critical nodes will stop andoil starvation will begin.

Repairing a pallet is not difficult, especially if the latter is made of steel. Such parts are dismantled and a dent is straightened with a hammer. If the part has received a hole, it can be welded or sealed with a hole by cold welding. Aluminum pallets are restored using argon welding - this is an inexpensive and effective way to restore this element.

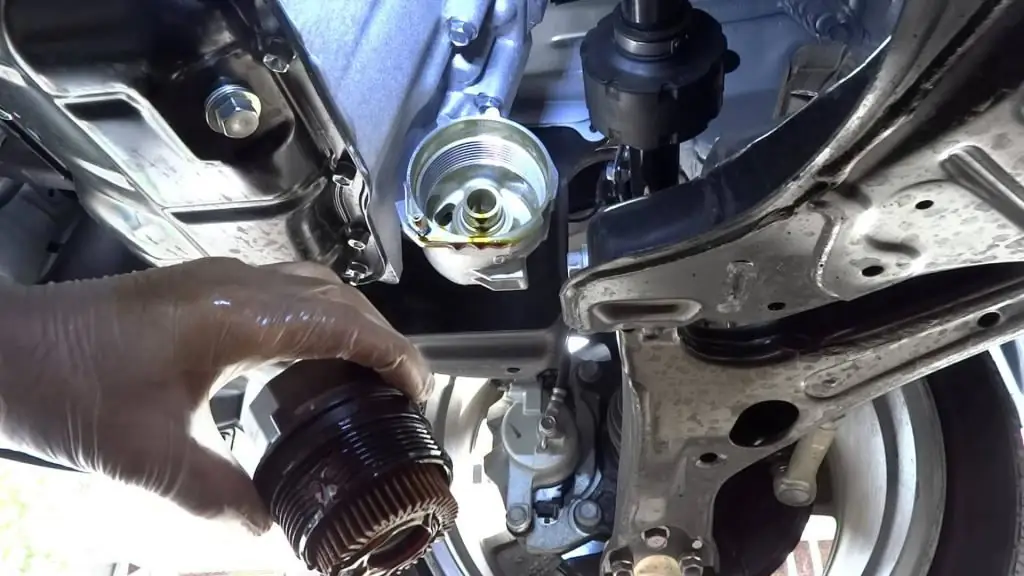

Replacing the oil pan

The whole procedure conditionally consists of two parts: the dismantling of the damaged part and the installation of a new one. First of all, remove the negative terminal from the battery, then dismantle the air intake. Next, the engine protection is removed. The oil must be drained into a suitable container. Then the bolts of the front support of the power unit are unscrewed, the stabilizer is removed, the lubricant level sensor is disconnected. After that, the oil pressure sensor connector is disconnected. On cars with automatic transmission, oil lines are also disconnected from the sump. Next, the stabilizer is removed and the engine rises. Then the springs of the front suspension system are removed. The front axle is lifted by a winch, the plastic covers are unscrewed. After this operation, the fasteners of the front axle are unscrewed, and this part is lowered.

Now you can unscrew the pallet, slide it forward and lower it. After installing a new element, the gasket is replaced. It is important to use engine oil pan sealant when installing. It will allow you to get a tighter connection, and after replacingoil will not flow.

How to protect the oil pan from damage

Crankcase repair is not cheap, and a car with a hole in the sump and grease that has already leaked out must also be taken to the repair site. Better take care of the engine right away. Engine oil pan protection must be installed on all vehicles that travel on the roads of our country. This is a special sheet made of steel, aluminium, plastic, titanium or stainless steel that covers the bottom of the engine.

Recommended:

Changing the oil in a Mercedes. Types of oil, why it needs to be changed and the main task of engine oil

A car is a modern vehicle that needs to be monitored every day. A Mercedes car is no exception. Such a machine should always be in order. Changing the oil in a Mercedes is an important procedure for a vehicle. In this article we will talk about how important it is to carry out this procedure, what types and types of oil are

Oil change in Toyota: types and choice of oil, specifications, dosage, do-it-yourself oil change instructions

The reliability of your car depends on quality maintenance. To avoid additional repair costs, it is recommended to use engine oil in a timely and correct manner. The operation of any car implies a number of regulatory requirements. Toyota oil change must be carried out according to the instruction manual. It is recommended to perform the procedure after every 10,000-15,000 km of the vehicle run

Changing the oil in the Chevrolet Niva engine: the choice of oil, the frequency and timing of oil changes, tips from car owners

The car's powertrain needs regular maintenance. The engine is the heart of any car, and its service life depends on how carefully the driver treats it. In this article we will talk about how to change the oil in a Chevrolet Niva engine. Despite the fact that every motorist can do this, there are some nuances that you must first familiarize yourself with

Engine oil change intervals. Diesel engine oil change interval

Frequency of oil change in engines of various car brands. How to choose engine oil? Detailed instructions for changing the oil. Tips from auto mechanics

Why does engine oil turn black quickly? Selection of oil for the car. Terms of oil change in the car engine

Why does engine oil turn black quickly? This question worries many motorists. There are many answers to it. Let's consider them in our article in more detail. We will also pay special attention to the most common types of additives used to improve oil performance