2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

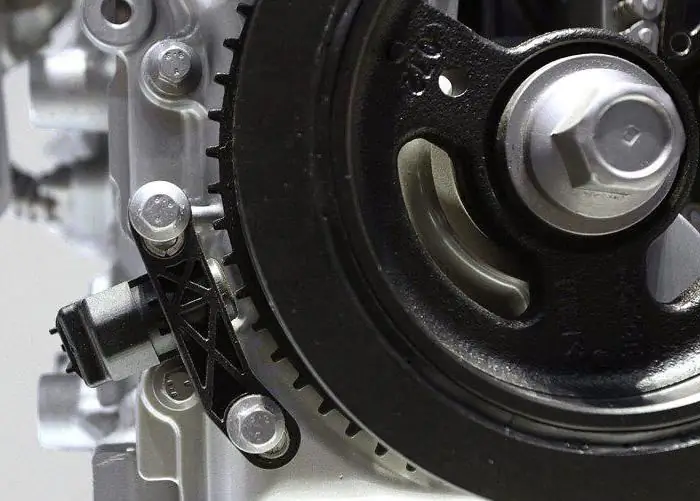

At first glance, the crankshaft pulley seems to be an unimportant detail, but despite this, the functioning of many vehicle systems depends on it. It is used not only in passenger cars, but also in lifting and construction equipment. The need to replace it often arises when installing a new crankshaft oil seal, as well as when the pulley structure is damaged.

Description

The work of many systems of the car is carried out due to the energy coming from the crankshaft. The design of the pulley has been improved over time, today several options have appeared, each of which is suitable for a particular vehicle and various operating conditions. They are fixed with bushings made of quality materials, thus simplifying installation and increasing the reliability of fastening.

The main purpose of a pulley is to transfer energy between shafts. It is of particular importance in the following cases:

- there is excessive transmission load on the belt;

- must prevent belt slippage.

How to choose

When choosing a toothed pulley, you should pay attention to the class of processing, the distance between the teeth and the form of manufacture. The surfaces of the teeth and the belt are subjected to constant loads, which places high demands on the quality of cutting and processing. The cutting of teeth is carried out in several stages on a milling machine or devices designed specifically for the manufacture of these parts. Cast iron products are somewhat different from other varieties, they are cast in molds that completely repeat the finished pulleys for timing belts and are processed using a milling machine.

Flanges on the pulley can either be absent or located on one or two sides. They are fixed in three ways:

- riveting with further milling;

- bolted connections;

- shrink fit (only applies to small part sizes).

Materials

Before buying a product, you need to decide on the materials that were used in its manufacture. The most common are cast iron, aluminum and steel. Cast iron is gradually fading into the background, as it is inferior in characteristics to modern alloys, and besides, it has a rather high cost. A gear pulley made of low alloy steel, which is resistant to corrosion, wear, mechanical damage, and can be heat treated, has gained sufficient distribution.

Calculation of gear and belt drive is done in the same way, but the elastic belt must be taken into account,acting as a transmission body. There are two main types of calculation: metric and inch. The calculation of the required number of teeth depends on the number of teeth and gear ratio. In some cases, idler rollers may be used to provide more grip.

Dismantling

In order to remove the old toothed pulley, it is necessary to remove the cover that hides the wires of the units, thus providing free access to the motor parts that need to be replaced. Further, the tension of the drive chain is loosened. After that, the tank with non-freezing liquid and the electric generator are removed. If the vehicle is equipped with power steering, the power steering belt must be removed.

Next, it remains to remove the mounting bolt that secures the toothed pulley to the crankshaft, but there may be difficulties associated with the direction of the thread. While the engine is moving, the bolt is constantly tightened, so an air wrench may be required at this stage of the work if hand force is not enough.

In the absence of special tools that greatly simplify the task, it is recommended to fix the wrench on the bolt to prevent it from turning. The car during work must be on jacks, or with the drive wheels removed. This is necessary so that the transport does not budge. The bolt will be unscrewed by turning the ignition key sharply, while the starter will make several revolutions and all that remains is to remove the bolt. After replacing the pulley, allparts are installed in reverse order.

What to look out for

It is also quite difficult to remove the “VAZ” toothed pulley from the seat. Torque is transmitted through a keyed connection, and the pulley itself is attached using a transitional fit. It is advisable to have a special puller with you, which will ensure smooth dismantling of the part with a minimum of effort. If difficulties arise, you can process the connection with WD-40. When removing, it is important not to damage the keyway, so you need to work carefully and slowly. If this rule is not observed, there is a possibility of chips and small cracks.

Recommended:

Alternator pulley: appointment, installation, repair

The most common cause of generator failure is a failed pulley. It is designed to protect the system from vibrations and provide the necessary belt tension. Belt drive tension can change even with minimal pulley deflection

Replacing the crankshaft pulley: instructions, tools, workflow

Internal combustion engines are equipped with additional equipment - these are generators, air conditioning compressors, a pump for the cooling system. All these devices receive torque from the crankshaft through a pulley. The latter eventually becomes unusable due to natural wear and tear. As a result, the car needs to replace the crankshaft pulley. Let's see how to perform this operation

Crankshaft pulley: removal and installation procedure

Whatever the car, sooner or later it will have to be repaired. If your car, for example, has a deformed crankshaft pulley, and you need to remove it, then for this you will have to put the “iron horse” on the parking brake, then use a jack to raise the front of the car and install it on special props

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

How to unscrew the crankshaft pulley yourself

Works related to the replacement of the engine timing belt, crankshaft and camshaft toothed pulleys, engine front oil seal, as well as the generator drive itself, require the dismantling of the crankshaft pulley. This element is available both on domestic cars and on foreign cars. Actually, most motorists have a question, how to unscrew the crankshaft pulley? And to be even more precise, the fixing bolt on the crankshaft flange, and in which direction to turn the key