2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:12

Internal combustion engines are equipped with additional equipment - these are generators, air conditioning compressors, a pump for the cooling system. All these devices receive torque from the crankshaft through a pulley. The latter eventually becomes unusable due to natural wear and tear. As a result, the car needs to replace the crankshaft pulley. Let's see how to perform this operation.

Destination

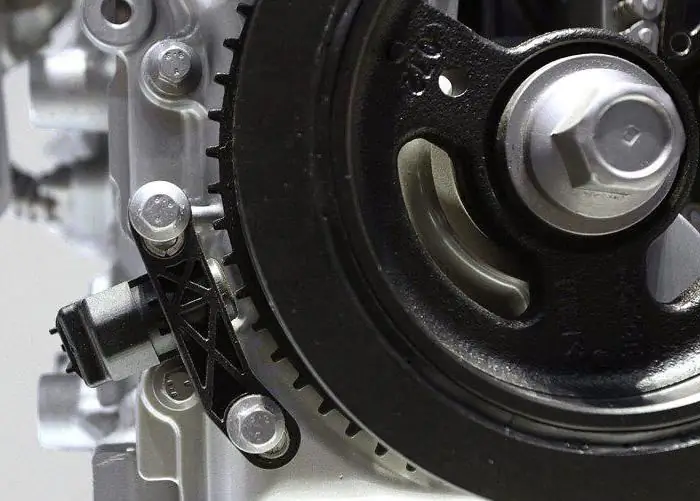

The pulley is designed to transmit torque to additional units. To do this, these same units have a reciprocal pulley. It is attached to the crankshaft by means of a keyway, and fixation is carried out with a nut or a bolt.

The pulley is a flat wheel with a special channel into which a rubber belt is installed. When the belt is sufficiently tensioned, it engages tightly with the pulley, and due to this, the belt drive works and transmits rotation. These elements for modern cars are mademainly from steel, aluminum, less often from cast iron.

Faults and checking

Before replacing the crankshaft pulley, it is necessary to assess the condition of the part. Pulleys and belt drives work thanks to the force of thorns that occurs between the contact surfaces. One of the most common causes of failure is wear due to natural wear on the working surfaces. Due to constant dynamic loads, the metal becomes cracked and chipped.

Another typical malfunction is key play in the keyed connection of the pulley and crankshaft. The backlash is caused by a worn fit of the element with the shaft. The mount is constantly untwisted due to vibrations, which further increases the backlash.

If you use such a pulley for a long time, then the keyway will develop even more, and in the end it will simply collapse. Often this is accompanied by unscrewing the crankshaft pulley bolt. The assembly then turns, completely destroying the pulley housing, the joint, and also the crankshaft.

How to diagnose?

To check the condition of the pulley, remove the belts, visually assess the condition of the edges and the case - you need to try to see cracks and signs of wear. Next, you should shake the pulley - if there are critical backlashes, it will feel good. The instructions for the engine must contain the parameters and dimensions of permissible wear. It will not be superfluous to check that the parts correspond to these dimensions.

What prevents the mechanism from being removed?

So, the diagnostics showed that the crankshaft pulley needs to be replaced. In any bookscar repair, this procedure is described very briefly, which suggests the simplicity of the operation. However, this is not the case.

The process is hampered by the inconvenient location of this pulley under the hood of the car. The mechanism is hidden behind the generator. Access to it is severely limited. Pulleys are damper and conventional - the first are equipped with an external ring to dampen vibrations. In order to gain access to the pulley mounting, loosen the belt tension bolts on the accessory drives. When dismantling, care must be taken in terms of the application of force. It is important not to break the elements that surround the pulley.

When the pulley is assembled at the factory, it is clamped with a bolt or nut with great force to ensure reliable fastening. During the operation of the internal combustion engine, the right-hand thread on the crankshaft and, accordingly, the pulley nut or bolt, further strengthens the clamp. High temperatures, environment, time - all this accelerates the process of destruction. It is also worth adding here the effect of oil and corrosion. Unscrewing the crankshaft pulley nut without knowledge of special techniques can be quite difficult.

If you disengage the clutch, the crankshaft can be easily turned with a key. Therefore, before trying to unscrew the nut, you need to securely fix the pulley - this eliminates turning during the process of unscrewing the nut. In the service station there are special devices for this - the element is screwed into the technological holes and an anti-rotation stop is formed.

If there are no devices, then the problem is solved with reliable stopsunder the wheels and the inclusion of fourth gear at the checkpoint. You can also fix the flywheel with a large screwdriver or pry bar.

How to unscrew the pulley?

Usually this mechanism is fixed on the end of the shaft with a power bolt or nut. The latter can be found on rear-wheel drive cars, it may have special protrusions for installing a “crooked starter”. To break the nut, experts use 36 or 38 wrenches with a long pipe welded on. Various devices are also used to fix the pulley. At home, the procedure for replacing the crankshaft pulley will be as follows.

First of all, the car is installed on a pit or overpass. Then, the fourth gear is turned on at the gearbox - this is done to prevent the crankshaft from turning while unscrewing the nut or bolt. Also, it will not be superfluous to tighten the handbrake.

The bolt or nut is tapped with a hammer, you can first pour the fasteners with liquid keys. If you have a gas burner, you can try to gently heat the bolt or nut. Next, with a socket head in size from a set of keys and an extension cord, with a sharp strong movement in a counterclockwise direction, the nut or bolt is shifted from its place. Then you can unscrew the mechanism.

Second way

If nothing worked in the first case, the following method is suggested. The gearbox is set to neutral, then the terminal is removed from the switch or the spark plug wires from the spark plugs to prevent sparking.

Next, put the key head onnut and rest the lever on the ground, or on the spars so that the pulley does not have the ability to turn to the right. Briefly turning on the starter, the crankshaft will rotate. It usually takes a few tries for the nut to come loose.

How to unscrew the bolt on the pulley?

Most front wheel drive models have a bolt instead of a nut. Here, the crankshaft pulley replacement instruction will be slightly different.

First of all, they raise the right side of the car with a jack, dismantle the wheel. Then the air filter is removed along with the block, the generator drive belt is removed, all elements that may interfere with easy access to the pulley are dismantled. To fix the mechanism in the clutch housing, the flywheel is blocked.

Further, with the help of a suitable socket from a set of keys with an extension cord, with a few sharp efforts to the left side, it is possible to break the bolt. If an attempt to unscrew manually did not lead to anything, you can try the above experience with the starter.

How to remove the pulley?

To replace the crankshaft pulley, you need to remove it directly from the shaft. It is very tightly fixed on the hub, and is also fixed with a key connection. Just by hand, the pulley will not come off the shaft.

It is recommended to use a special puller. The device has paws for gripping the edges of the pulley and a central stop that rests against the center of the shaft. If there is no puller, then you can remove the pulley with two mounts. It is important not to apply excessive force during dismantling and notdamage the key and keyway.

It is necessary to install a new pulley back on the shaft only after lubricating the seats, so as not to apply much force and not to warp the pulley on the shaft.

Conclusion

So, we looked at how to replace the crankshaft pulley. As you can see, this operation can be done by hand.

Recommended:

Replacing the timing on the "Prior": instructions, work technology and the necessary tools

One of the most popular cars today is the Lada Priora. Replacing the timing on this model, as it turned out, is a fairly common phenomenon. In general, Priora is a good car. It has a relatively modern design and is equipped with a reliable VAZ-21126 engine - a 16-valve engine with a displacement of 1.6 liters. But the quality of the timing belt is a significant drawback for Priora

Crankshaft pulley

At first glance, the crankshaft pulley seems to be an unimportant detail, but despite this, the functioning of many vehicle systems depends on it. It is used not only in passenger cars, but also in lifting and construction equipment

Crankshaft pulley: removal and installation procedure

Whatever the car, sooner or later it will have to be repaired. If your car, for example, has a deformed crankshaft pulley, and you need to remove it, then for this you will have to put the “iron horse” on the parking brake, then use a jack to raise the front of the car and install it on special props

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

How to unscrew the crankshaft pulley yourself

Works related to the replacement of the engine timing belt, crankshaft and camshaft toothed pulleys, engine front oil seal, as well as the generator drive itself, require the dismantling of the crankshaft pulley. This element is available both on domestic cars and on foreign cars. Actually, most motorists have a question, how to unscrew the crankshaft pulley? And to be even more precise, the fixing bolt on the crankshaft flange, and in which direction to turn the key