2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Works related to the replacement of the engine timing belt, crankshaft and camshaft toothed pulleys, engine front oil seal, as well as the generator drive itself, require the dismantling of the crankshaft pulley. This element is available both on domestic cars and on foreign cars. Actually, most motorists have a question, how to unscrew the crankshaft pulley? And to be even more precise, the fixing bolt on the crankshaft flange, and in which direction to turn the key. Let's take a look.

Faulty crankshaft pulley

The main faults include:

- wear of the element itself;

- presence of cracks on the pulley housing;

- backlash;

- alternator drive belt slippage.

Also, in addition to wear on the pulley running surface, slippage can also occur due to wear on the drive belt. Hechanges every 60 thousand kilometers.

Which way to unscrew the crankshaft pulley

This question is asked by many motorists. In order to prevent thread stripping or, even worse, twisting of the bolt head, it will not prevent the driver from figuring out which way to unscrew the crankshaft pulley bolt.

Since the thread on the pulley fixing element and the flange is the usual right-hand thread, it is unscrewed in the same way as the rest of the car nuts (counterclockwise).

Features of work

At first glance, there is nothing difficult in simply removing the bolt that secures the pulley to the engine crankshaft flange. However, this is not quite true. The crankshaft pulley bolt is very rarely unscrewed and always sticks. Therefore, there is a risk of breaking it. First we need to get to this pulley. To do this, the bolt fixing the generator to the tension bar is unscrewed. The latter is attached to the engine block.

The alternator is shifted towards the engine, and the drive belt is removed from the pulleys. It can be serrated or toothed. Now, having reached the desired element, proceed to further actions.

Tools for the job

In the case of a manual transmission, the crankshaft pulley bolt can be unscrewed with a box wrench or socket. It is better to take a regular collar. Ratchet in most cases does not withstand such a load (even if it is the strongest) and as a result crumbles intoparts. It is not recommended to use an open-end wrench or gas wrench during the dismantling of the crankshaft pulley.

The first tool may break, and the second will only ruin the edges of the bolt, and next time it will be even more difficult to unscrew it. In case of severe damage to the edges, it will have to be drilled and removed in parts, which will be unpleasant for the car owner. This will increase the time to replace the element.

How to unscrew the VAZ crankshaft pulley

On domestic cars of the VAZ "Classic" family, as well as on other cars, the element is removed in the same way. The only difference will be which gearbox is installed on the car in which such work is performed. In which direction to unscrew the crankshaft pulley bolt? Definitely counterclockwise.

To simplify the task, you can call an assistant who must engage direct gear (3 or 4) and keep the brake pedal depressed. At the same time, you will unscrew the pulley mounting bolt. If the car is rear-wheel drive, then you can do without an assistant. Just put the car on the handbrake and unscrew the bolt in the same way. You can work from the side of the hood or down in the inspection ditch. The main thing is that it is convenient to work. You can also jack up the car and remove the front right wheel.

This will provide good direct access to the crankshaft pulley which is unscrewed by the extension socket. The bolt of the mechanism rarely "gives in" immediately andconstantly sticks with a thread to the inner hole of the crankshaft flange. Therefore, it is always very difficult to break it. If it is not possible to unscrew the pulley mounting bolt, then a long wrench or pipe can come to the rescue. The element is put on the key. Grasping the very edge of the collar, gathering, as they say, all the forces into a fist, you should try to remove it again. Actually, the longer the lever, the easier it is to work.

For owners of cars with automatic transmission

How to unscrew the crankshaft pulley on the machine? If an automatic transmission is installed, then the “Parking” gear is set on a rear-wheel drive car. The handbrake is turned on and then the element is unscrewed in the same way as on a mechanical box. It is more difficult if the car turned out to be front-wheel drive. In this case, removing the element as on the mechanics (with the gear engaged and the brake pressed) will not work.

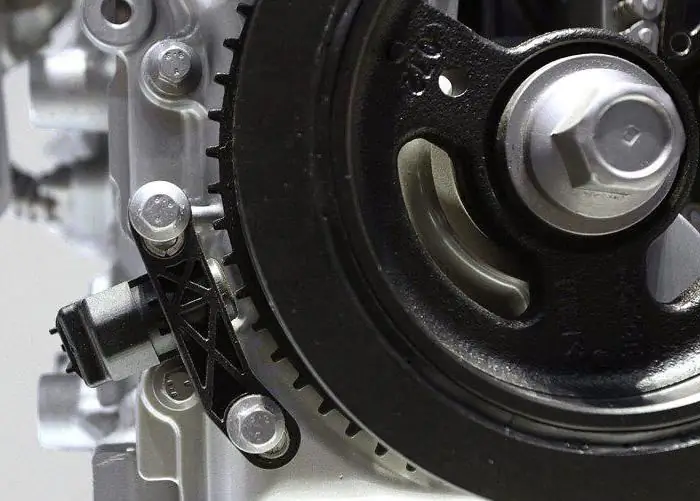

There is a great risk of damage to the gearbox. In this case, you need to lock the crankshaft so that it cannot turn in another way. Insert the mount between the teeth of the engine flywheel ring gear through the hole in the gearbox bell. She is supported so that she cannot come off and not ruin the teeth on the flywheel. In some cases, to get to the flywheel, you need to unscrew the engine starter. This will require a viewing hole, lift or overpass.

Second dismantling method

There is another tricky way to unscrew the crankshaft pulley. It is done independently without the presence of an assistant. Having previously removedgenerator drive belt, a head or a ring wrench is put on the bolt of the mechanism, the handle of which rests against some surface.

It is not worth resting it against the body or other parts of the engine compartment. When unscrewing the key, it can damage units with rubber pipes, scratch and even damage the body. In the future, it will become clear why. It is best to rest the key handle on the ground or floor by placing a wooden board under it. The main thing is that there is a solid and even surface. If the key does not reach the stop, then by moving the head or rotating the crankshaft, rest it against a hard surface.

Now, turning on the ignition, you need to turn the engine over with the starter. Its strength is more than enough to break the pulley fixing bolt. The main thing is not to overdo it and correctly rest the key so that it stands firmly in place and does not stagger. Even due to a slight displacement, it will come off the bolt head and damage the engine compartment. In no case should you start the engine, and if you still managed to do it, then turn it off immediately.

To prevent the engine from starting, you can remove the fuel supply hose from the fuel pump to the carburetor if it is a carburetor engine, or the hose included in the fuel rail if the engine is injection.

Conclusion

Now you know how to unscrew the crankshaft pulley yourself. The owner of the car needs to approach this work with great responsibility. Allowing the slightestmistake, additional repairs can be provided, which will be accompanied by large monetary costs. If the head of the crankshaft pulley fixing bolt breaks off, the thread will deteriorate or parts of the engine compartment will be damaged. Therefore, correctly following the above recommendations, the work will be fast and high-quality without the occurrence of adverse situations. On this question, how to unscrew the crankshaft pulley bolt with your own hands can be considered closed.

Recommended:

Crankshaft pulley

At first glance, the crankshaft pulley seems to be an unimportant detail, but despite this, the functioning of many vehicle systems depends on it. It is used not only in passenger cars, but also in lifting and construction equipment

Replacing the crankshaft pulley: instructions, tools, workflow

Internal combustion engines are equipped with additional equipment - these are generators, air conditioning compressors, a pump for the cooling system. All these devices receive torque from the crankshaft through a pulley. The latter eventually becomes unusable due to natural wear and tear. As a result, the car needs to replace the crankshaft pulley. Let's see how to perform this operation

Crankshaft pulley: removal and installation procedure

Whatever the car, sooner or later it will have to be repaired. If your car, for example, has a deformed crankshaft pulley, and you need to remove it, then for this you will have to put the “iron horse” on the parking brake, then use a jack to raise the front of the car and install it on special props

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

How to unscrew the lock on a wheel without a key: ways

How to unscrew the lock on the wheel without a key, if it is lost or broken, depends on the type of protection device itself. If the secret bolt lends itself to self-twisting without welding, then use one of the methods presented in the article