2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

If you ask any motorist what is the most important part of the car, most will answer that it is the engine, as it sets the car in motion. Others will say that the most important thing is the body. Still others will say that you can’t go far without a checkpoint. But very few remember the suspension and how important it is. But this is the foundation on which the car is built. It is the suspension that determines the overall dimensions and features of the body. The system also determines the possibility of installing a particular engine. So, let's figure out what a car suspension is.

Destination

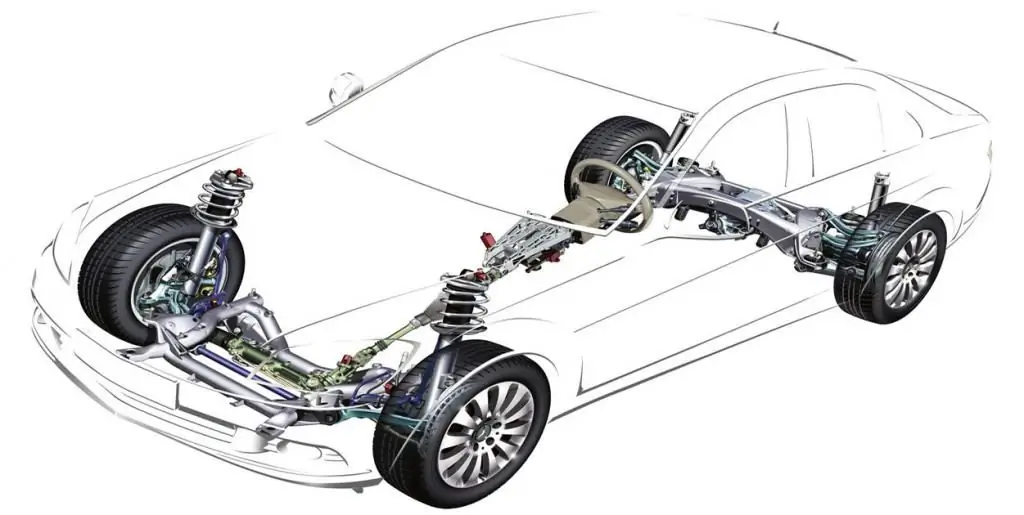

This is a complex of very closely working elements and devices, the functional feature of which is determined by providing an elastic connection between the sprung mass and the unsprung mass. Also, the suspension system reduces the load that is placed on the sprung mass, more evenly distributing the dynamics acrossthe whole car. Among the most important components in the suspension of any car, there are several elements.

So, elastic elements are designed to ensure a smooth ride. Due to them, the effect of vertical dynamics on the body is reduced. Damping elements and devices are designed to convert vibrations into thermal energy. Due to this, the dynamics of movement are normalized. The guide parts process the lateral and longitudinal kinetic energy to the moving wheels of the car.

Regardless of what type of chassis, the general purpose of a car's suspension is to dampen incoming vibrations and noise, as well as smooth out the vibrations that are bound to occur when driving on smooth and uneven surfaces. Depending on the specifics of the car, the design features and type of suspension will vary.

How does the system work?

Regardless of the type of system, this complex includes a set of elements without which it is difficult to imagine a workable running gear. The main group includes elastic buffers, distribution parts, shock absorbers, rod, and fasteners.

Elasticity buffer is needed to analyze and transmit information to the body in the process of processing road roughness. It can be springs, springs, torsion bars - any parts that smooth out vibrations.

The distribution parts are both fixed in the suspension system and attached to the car body. This allows power to be transferred. These elements arelevers.

Shock absorbers use the hydraulic resistance method. The shock absorber resists the elastic elements. There are two types - one-pipe and two-pipe models. Devices are also classified into oil, gas-oil, and pneumatic.

The rod is designed to stabilize the roll bar. This part is part of a complex complex, which consists of supports, as well as lever mechanisms mounted on the body. The stabilizer distributes the load during turns and similar maneuvers.

Fasteners are often bolted connections and various bushings. Silent blocks and ball bearings are among the most popular elements in different types of suspensions.

Types of suspension systems

The first pendants appeared at the beginning of the 20th century. The first designs performed only the function of connection, and all the kinetics were transferred directly to the body. But then, after numerous experiments and tests, developments were realized that made it possible to significantly improve not only the design. These experiments have significantly raised the potential for future exploitation. Now you can meet only a few representatives of those developments or even segments. Each type of suspension is worthy of a separate review or even an entire article.

MacPherson

This development, which was created by the designer E. McPherson, was first used about 50 years ago. Structurally, it has the only lever, stabilizer and swinging candles. Those who know well what a suspension is will say that thisthe type is imperfect, and they will be right. But with all the shortcomings, this system is very affordable and popular with most manufacturers of budget cars.

Double lever systems

In this case, the guide part is represented by two levers. This can be implemented in the form of diagonal, transverse and longitudinal lever systems.

Multi-link systems

Unlike double levers, here the structure is more serious. Therefore, there are advantages that provide the car with a smooth and even ride, improved maneuverability. But only premium cars are equipped with such solutions.

Torsion-lever systems

This design is similar to the above types. But instead of springs traditional for lever-type suspensions, torsion bars are used here. Despite its apparent simplicity, this solution significantly expands the efficiency of operation. The components themselves are easy to maintain and are configured as you like.

De Dion

This suspension was designed by engineer De Dion from France. Its peculiarity is that it reduces the load on the rear axle. The main gear housing is not fixed to the beam, but to a part of the body. This solution is found on all-wheel drive off-road cars. On passenger cars, this approach is unacceptable. This can cause various problems during acceleration and deceleration.

Rear dependent suspension systems

We have already covered what suspension is, and now let's move on to the rear systems. This is a type of passenger car suspension familiar to everyone, which was very fond of Soviet engineers. In the USSR, this type is very commonapplied, integrated and invented. The beam is attached to the body by means of elastic springs and trailing arms. But with excellent handling and stability in motion, the weight of the rear beam can overload the gearbox and crankcase. However, such a rear suspension on VAZ, Logan and other budget models is still popular.

Semi-dependent

Unlike the dependent circuit discussed above, there is a crossbar here. It is connected with two trailing arms.

Swinging

In this type, the semi-axes are the basis of the design. Hinges are attached to one of the ends of the part. The axles themselves are connected to the wheels. When the vehicle is moving, the wheel will be perpendicular to the axle shaft.

Trailing and transverse arms

Here the main structure is the trailing arm. It must unload the support forces that act on the body. This system is very heavy, which does not make it popular in the market. And in the case of trailing arms, everything is better - this is a more flexible type in setting. Support arms reduce stress on suspension hardware.

Suspension with oblique arms

The solution is very similar to the trailing arm system. The difference is that the axles on which the levers swing are, in this case, set at a sharper angle. These systems are most often installed on the rear axle. The suspension can be found on German-made cars. When compared with the longitudinal type, here the rolls in the turn are significantly reduced.

Double wishbone and trailing arm suspension

Unlike a single lever system, there are two levers per axle. They are placed transversely or longitudinally. To connect the levers, torsion bars and springs can be used. In addition, springs are often used. The suspension is compact but not balanced for bumpy rides.

Pneumatic and hydraulic suspension

These solutions use fully pneumatic or hydropneumatic elastic elements. By themselves, these details are not the final version. They only make driving more comfortable.

Both the car's air suspension and hydraulic are quite complex, both provide high ride comfort and excellent handling. Such systems can be connected to MacPherson or multi-link solutions.

Electromagnetic

This is an even more complex type, and the design is based on an electric motor. Two functions are performed at once - both a shock absorber and an elastic element. At the head is a microcontroller and a sensor. This solution is highly safe, and the mechanism is switched by means of electric magnets. Naturally, the cost of the kit is very high, so it is not found on production car models.

Adaptive suspensions

We know what a pendant is and what it is for. And this system is able to adapt itself to the conditions of movement and the driver. Electronics is able to determine the degree of vibration reduction. She tunes indesired operating modes. Adaptation is performed by electromagnets or by liquid method.

Faulty suspension systems

Automakers are working hard on suspension reliability. Many cars are even equipped with enhanced systems. But the quality of the roads reduces the efforts of engineers to zero. Drivers are faced with various vehicle suspension malfunctions. There are several typical problems.

So, the corners of the front wheels are often violated. Often the levers are deformed, the stiffness of the springs is reduced or they break. For one reason or another, the tightness of the shock absorbers is violated, the shock absorber supports are damaged, the bushings of the stabilizers wear out, the ball bearings and silent blocks wear out.

Even with regular maintenance, the suspension is still a consumable item in Russia. Literally every year after the winter, drivers have to be puzzled by replacing the car's suspension.

Diagnostic DIY

The system should be diagnosed if there are problems with the car. This is the lack of rectilinear movement, various vibrations at speed, buildup of the body when driving around or passing obstacles, uncharacteristic sounds, hitting the body when hitting various obstacles.

Diagnosis of the front suspension of a car can be performed both manually using a mount, and on a computer stand. With the help of the mount, each element of the system is checked in turn for the presence of backlash. A visual inspection will also help identify the malfunction - you can visually evaluatestate of silent blocks and other elements. Ball joints are diagnosed by hand. If the support goes tight in its clip, then it is working. If she walks easily, then she should be replaced. In the VAZ suspension, this can be done without replacing the lever. On most foreign cars, the ball joint goes as a whole together with the lever. Although there are craftsmen who are engaged in the restoration of ball joints or drilling rivets on the lever and installing bolted supports. This allows you to save a lot.

But to find out exactly what condition the suspension is in, computer diagnostics of the car's suspension will help. This is a special stand where the entire system is checked with the help of numerous sensors. The computer will very accurately assess the condition and show worn and replacement parts.

Suspension Service

Suspension life depends on maintenance. How often you need to carry out the service, there is no exact answer. The term depends on the nature of the ride and the operation of the car. If the car is treated with care, it will be enough to service the suspension of the car once a year. But it happens that strange sounds and subsidence of the car happen more often. In this case, it is necessary to diagnose and replace worn parts. Usually maintenance comes down to replacing worn silent blocks, ball bearings and other elements.

If the car's rear dependent suspension fails, the rear wheels become a house. To solve the problem, it is enough to replace the repair kit. It does not take a lot of time. That's all there is to sayabout suspension maintenance.

Suspension repair can be difficult - the system has to work in difficult conditions. And often drivers are faced with the fact that the fasteners are not unscrewed due to corrosion. At service stations, craftsmen use pneumatic or electric tools, which greatly facilitates the process of unscrewing fasteners. Repair and maintenance of the suspension at the service station will require less time than if the same was done in a conventional garage.

So, we found out what the chassis of a car is, what types it is and what functions it performs in a car.

Recommended:

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

Air suspension: principle of operation, device, pros and cons, owner reviews. Air suspension kit for car

The article is about air suspension. The device of such systems, types, principle of operation, pros and cons, reviews, etc. are considered

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

What type of car is the best. The main types of cars and trucks. Car fuel types

Life in the modern world is unimaginable without various vehicles. They surround us everywhere, almost no industry can do without transport services. Depending on what type of car, the functionality of the means of transportation and transportation will be different

Car air conditioner compressor: functions, device, fault repair

The car air conditioning compressor is one of the main elements of the system. Malfunctions in it worsen the operation of the car and require mandatory repairs