2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

Each driver should not only know how many types of car suspensions exist, but also understand what functions are assigned to this part of the vehicle. This is especially true for those people who are associated with cars professional activities. Moreover, the experience and experience of the driver is unimportant, knowing the structure of your vehicle in any case will not harm.

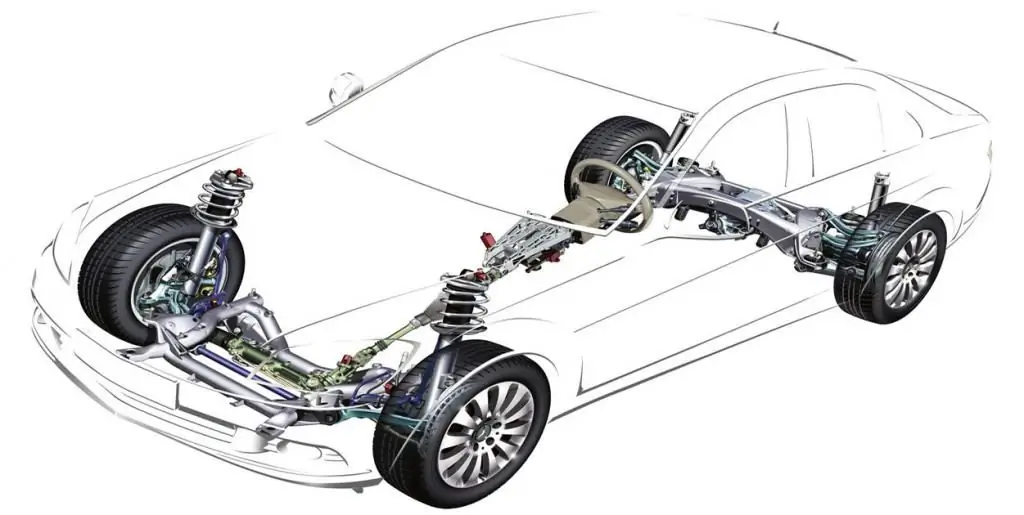

What is a car suspension? In fact, this is a unit or even an entire structure, which consists of several parts. Moreover, their attachment to each other is adjusted in a special way. By virtue of its structure, the body of any vehicle is connected to the wheels, which makes it possible to move. At the same time, the connection itself can be elastic or rigid, depending on the elements and parts of the suspension.

It is this whole system that smoothes or damps vibrations that are caused by irregularitiesroad surface. But how is it organized? There are several types of pendants, but they all have some similarities in their design.

Guides

Just due to them, the wheels are connected with the body of the vehicle, transferring the force of movement to it. In addition, it is determined exactly how they move relative to the car body itself. This term should be understood as various levers for fastening and connecting parts. They can be transverse, longitudinal, and double.

Elastic component

This is a kind of intermediate link between the wheels and the body. The entire load from the unevenness of the roadway is perceived by him, after which it is transferred to the body of the vehicle. These elements can be made not only from metal, but also from other affordable and durable materials.

As a rule, springs, springs, torsion bars are produced from metal for different types of suspensions of trucks (or cars). Other elements can be made of rubber (buffers, bumpers - but, as a rule, they are part of metal parts).

Extinguishing device

Under this definition is nothing more than the shock absorber itself. Its purpose is to reduce the amplitude of vibrations of the car body, which are just caused by the work of elastic elements.

Typically, all types of shock absorbers rely on the hydraulic resistance that occurs when fluid flows from one cavity to another through the calibration holes of the valves.

As for these cavities, thenshock absorbers can be single-tube (1 cylinder) or twin-tube (2 cylinders).

Anti-roll bar

Mandatory component for any pendant. This detail helps to counteract the increase in the intensity of the roll when cornering. This work is possible due to the distribution of the weight of the car on all its wheels.

In fact, the stabilizer is an elastic rod connected to all parts of the suspension through racks. It can be placed not only on the front, but also on the rear axle of the vehicle.

Wheel support

Usually, for most types of car suspensions, its location is the rear axle of the car. Its task is to take all the load from the wheels and distribute it between the suspension arms and shock absorbers. But there is also a similar device on the front axle. Only it has a slightly different name - the knuckle.

Mounting elements

Without them, the existence of the entire suspension is impossible, since it is they that ensure the connection of all parts to each other. They are also responsible for attaching them to the car body.

The main type of such fastening is a rigid connection with bolts. Rubber-metal bushings (they are also silent blocks), ball joints are also used.

Functional purpose

Because the suspension transmits the impact from the wheels to the car body, it is necessary to design it in such a way that it has increased strength and durability. Butwhat exactly is the role of the suspension besides connecting the wheels to the body of the vehicle?

The suspension of any car is responsible for performing important tasks:

- damping vibrations from the wheels;

- ensure a smooth ride;

- Ensuring constant contact of the wheels with the road, which, in turn, affects the handling and stability of the car;

- It is precisely due to the suspension that the connection between the wheels and the body is elastic.

Currently, many types of car front suspension (in addition to many elements) also include electronic devices and various sensors. This allows you to increase the comfort of movement of the car, but at the same time makes the system more complex in the device.

Varieties of running gear elements

From the time the first transport appeared to the present day, several types of automobile suspensions have been designed. At the same time, an ideal option has not yet been developed that would suit all parameters and indicators.

For this reason, it is impossible to single out any one optimal option from the entire existing variety. This is because each type of car suspension has not only advantages, but also disadvantages, which determines their application.

But despite the rather extensive classification, all types belong to one of two suspension groups:

- dependent;

- independent.

The last group is (for obvious reasons) the most popular. Herthe main difference is that the wheels are not rigidly connected to each other, and one is not able to influence the others. There is also an intermediate option - a semi-independent suspension.

Dependent group

Detailed analysis of the types of car suspension and their arrangement will begin with a consideration of the dependent group. She "migrated" to cars from horse-drawn carts and at first remained the only existing option. Over the entire period of its existence, it has undergone significant changes, but the essence of its work has never changed.

Dependent suspension implies a rigid connection of wheels connected by one axle. This prevents them from moving separately from each other. In other words, if one of them falls into a hole, this will inevitably lead to the displacement of the other.

For rear-wheel drive vehicles, the rigid connection of the wheels is provided by the rear axle, which is also part of the transmission. In front-wheel drive vehicles, a special beam provides a rigid connection.

As for the elastic elements, initially they were springs, but now the use of springs has completely replaced them. Shock absorbers act as a damping element here. They can be installed separately from the elastic elements or located coaxially with them - a shock absorber placed inside the spring.

Advantages and disadvantages of dependent suspension

The advantages and disadvantages of dependent types of car suspension are collected in one bottle. On the one hand, the main advantage of this variety is the simplicity of design, whichhas a positive effect on reliability. In addition, excellent traction is ensured when it comes to flat surfaces.

But on the other hand, there is a serious drawback, which lies in the possibility of losing contact of the wheel with the road at the time of cornering. Due to the fact that the rear axle is combined with the transmission parts, the bridge turns into a massive structure with quite impressive dimensions. You can feel it when you look at the freight transport.

Due to these features, such a suspension is used only for the rear axle, while in relation to the front, such an implementation is simply impossible. In addition, today the dependent group has practically lost its relevance and its use has been reduced to a minimum. However, it can still be found in trucks, as well as among full-size frame SUVs.

Independent suspension type

The independent type of car suspension has an advantage, and at the same time the main difference from the opponent discussed above, is that the wheels on the same axle are not mechanically connected to each other. That is, it may be so when one of them rotates and the other does not. This option was developed after finding out certain disadvantages of dependent suspension. Here, each wheel has its own set of parts: elastic, damping, guiding elements.

McPherson Suspension

This design is named after the engineer Earl McPherson, who developed it in 1960. In the language of motorists, it is also called a "rocking candle."The device is represented by one lower arm, a block of a spring element, an anti-roll bar.

A feature of this type of suspension is the use of a shock absorber strut, it was popularly called it a candle. It consists of a shock absorber and a spring. In the lower part, this component part is attached to the wheel hub, and at the top it is fixed on the support (glass) of the car body.

This type of car front suspension performs several important tasks at once. The rack not only receives and dampens vibrations, but is also the attachment of the wheel to the vehicle body. The functionality of the transverse levers is to provide a movable connection between the wheel and the body of the car, as well as to prevent its longitudinal movement. As for the stabilizer, this is, in fact, a torsion bar, which has an equally important role - to counteract the twisting force.

McPherson suspension is used not only for the front, but also for the rear axle, which determined its immense popularity. Its advantages include compact size, simplicity of design, as well as reliability. As for the minuses, this is a change in the camber angle with a significant wheel travel relative to the car body.

Independent link arms

This suspension is as common as McPherson. This type is divided into two main systems:

- two-lever;

- multi-link.

The double-lever design also uses a shock absorber strut, only its function is only dampingarising fluctuations. The fastening of each wheel of one axle (usually the front one) is provided directly by transverse levers (upper and lower).

In this type of front suspension of a passenger car, the levers themselves are made in the form of an A-shape, which eliminates the longitudinal movement of the wheels. They are also of different lengths (the upper one is noticeably shorter than the lower one). This allows you to maintain the camber angle even with significant movement of the wheel relative to the car body.

Unlike the same "MacPherson", the two-lever system is more massive, metal-intensive and difficult to maintain. However, more parts do not affect the reliability of the suspension.

The multi-link system is a modified version of the double-lever suspension type. Instead of two A-arms, up to 10 trailing and transverse arms are usually used here.

This design option has the best effect on the smoothness of the vehicle and its handling. It also allows you to maintain the angle of the wheels, regardless of the conditions of the suspension.

However, there is also a downside here - this type of rear suspension of a car (also happens on the front axle, for example, on Audi) is more expensive and even more difficult to maintain. For this reason, in terms of use, it is noticeably inferior to the same McPherson system or a two-lever system. It is found only in luxury cars, which are not cheap.

Other options

There are othersvarieties.

- Suspension with oscillating axle shafts - here, instead of one, two axle shafts are used. Each of them is attached to the chassis by means of a hinge. Due to this, the wheel assumes a perpendicular position with respect to the axle shaft. When cornering, the lateral forces will tend to toss the vehicle, which negatively affects the stability of the car. For this reason, trucks are mainly equipped with such a suspension.

- Dubonnet suspension - this type was used on cars in the first half of the 20th century. On each side of the hull there was a lever with a jet thrust, which acted on a spring. The rod itself was connected to the casing, where there was a spring that transmitted forces during braking. Since liquid was constantly leaking from the casing, this type did not take root.

- Trailing arms - in this type of car suspension, each wheel on the same axle is attached on both sides to a lever that is rigidly connected to the frame. With this type of suspension, only the wheelbase changes, while the track remains the same. However, the stability in this case is not very good, and the wheels can turn with the body. As a result, this negatively affects the grip of the tires on the road. During the movement of the car, the entire load is perceived by the trailing arms, which is why the suspension lacks stiffness and weight. As for the pluses, there is an opportunity to increase the interior space due to a flat floor.

- Slanting levers - in fact, this is an improved version of the trailing arm system. It is relevant for the leading axle. Thanks toWith this design, the possibility of changing the width between the wheels is minimized. At the same time, there is an effect of rolls on the inclination of the wheels. If you increase the fuel supply when entering a turn, the rear of the car body squats slightly, which causes the front wheels to collapse. With a decrease in fuel supply, everything happens the other way around: the front of the hull becomes lower, and the rear rises.

There is another type of car suspension - De Dion, which was designed by Albert De Dion. Its peculiarity is that the main gear housing is attached to the vehicle body itself and is separated from the bridge beam. Torque from the power unit is also transmitted to the drive wheels through the axle shafts. This option allows you to optimize the weight of the vehicle. Many engineers opt for De Dion suspension to lighten the rear axle.

However, there are also disadvantages here - intensive acceleration or braking leads to the rocking of the car. That is, at the start, the car crouches and “nods” when braking. To eliminate such an undesirable effect, additional guide elements were used.

Semi dependent option

You can say that this is the golden mean between dependent and independent systems. If you pay attention to the appearance, you can find features of a dependent suspension - there is a beam that is made integral with the trailing arms, and the hubs are already attached to them. With the help of the same levers, the beam is connected to the car body. Damping elements here -springs and dampers.

In other words, this is the same axle that connects both wheels, but unlike a fully dependent suspension, the beam here is of a torsion type, and therefore is capable of twisting. Due to this, the wheels can move relative to each other in the vertical plane by a certain degree.

Due to its simple design and increased reliability, front-wheel drive vehicles (for the rear axle) are often equipped with this type of suspension.

Diagnostic measures

We have already familiarized ourselves with the purpose and types of car suspensions. Of course, the topic of this article does not list all varieties, but only the most famous and common options. Although some of them have already sunk into oblivion. Now it is worth touching on another important point.

The car's suspension is subjected to intense dynamic loads, and therefore it is extremely important to detect a malfunction in a timely manner. To do this, it is necessary to regularly diagnose the chassis. The rear suspension is the easiest to check because there are no controls. During the diagnostics, shock absorbers, rubber seals (for any type of suspension) are inspected, and it is also necessary to make sure that the jet rods are working.

A dull thud will be evidence that something is wrong with the exhaust system - the muffler components are lost or completely out of order. To be convinced of this, it is enough to swing the muffler.

Diagnosis of the rear suspension should also be carried out, checking each part for cracks and foreign objects. Also to be appreciatedbeam state in dependent suspension types.

As for the types of front suspension, it is necessary to focus on the condition of the main parts:

- knuckles;

- shock absorber struts;

- levers;

- Tie Rod Ends;

- silent blocks.

Anthers are located on the steering tips, which often simply breaks. In this case, a visual inspection is sufficient to determine such a malfunction.

Most drivers who are interested in the types of car suspensions are wondering: how often should diagnostics be done? Car service stations recommend an inspection after every 10,000 km, at least.

Reviews

Many car enthusiasts are interested in the opinion of other drivers regarding a particular type of suspension. On various forums dedicated to this area, you can find reviews of professional auto mechanics or the points of view of drivers who have many years of practice behind them.

Someone notes that the springs are out of competition, while others are more inclined in favor of "MacPherson" or a two-lever system. Rarely anyone mentions dependent suspension. After all, most people are trying to buy cars with maximum comfort at an affordable cost. The dependent type is an obsolete variant that can no longer be found among modern cars.

Recommended:

Types of car suspensions, device and diagnostics

Which is the most important part of the car? Almost all motorists will argue that, of course, the engine, since it is he who sets the car in motion. Others will say from the body, about the transmission. But no one will say about the suspension of the car, but this is the foundation on which the car is built. It is the suspension that determines the overall dimensions and features of the body, and also affects which engine will be installed on a particular car. Suspension is an important and complex knot

Engine diagnostics: what is included and the cost. Computer diagnostics

Engine diagnostics is a set of measures to identify deviations in the operation of components that can disable an expensive unit. All necessary tests are included in the full cost of the service. However, to reduce the price, the masters reduce the established list

Gas on the Niva-Chevrolet: features, benefits and reviews

"Niva" - perhaps the most famous Russian SUV. Unfortunately, for the entire time of production, this machine has not undergone significant upgrades. Significant changes came only with the release of a new model - the Chevrolet Niva. The car received a different body and interior, but the engine remained the same. As a result, many problems "migrated" to the new Niva. This is not only low power, but also high fuel consumption. On average, a Chevrolet Niva consumes about 15 liters of gasoline in the city

How to lighten the flywheel with your own hands: features, benefits and reviews

Today there are many ways to increase the power of a car engine. Fans of speed and drive often decide to lighten the flywheel. Let's see what advantages can be obtained from such a replacement, what features this process has and whether it is possible to do the process of relief with your own hands in the garage

Pirelli Formula Energy tires: reviews, features and benefits

What are the reviews about "Pirelli Formula Energy". What are the main features of the presented tires? What are their advantages compared to analogues from other global brands? What is the opinion of representatives of independent rating agencies about these tires?