2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

The fuel supply system is needed for the supply of fuel from the gas tank, its further filtration, as well as the formation of an oxygen-fuel mixture with its transfer to the engine cylinders. Currently, there are several types of fuel systems. The most common in the 20th century was the carburetor, but today the injection system is becoming increasingly popular. There was also a third one - single injection, which was good only because it allowed to slightly reduce fuel consumption. Let's take a closer look at the injection system and understand its working principle.

General provisions

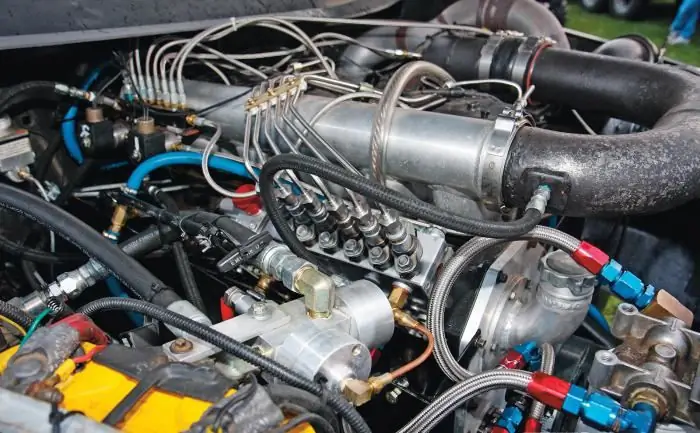

Most modern engine fuel systems are similar. The difference can only be at the stage of mixing. The fuel system includes the following components:

- The fuel tank is a compact product that has a pump and a filter for cleaning mechanical particles. The main purpose is fuel storage.

- Fuel lines form a complex of hose and tubes to move fuel from the tank to the mixing system.

- Devicemixture formation. In our case, we will talk about the injector. This unit is designed to obtain an emulsion (air-fuel mixture) and supply it to the cylinders in time with the engine.

- Control unit for the mixture formation system. It is installed only on injection engines, which is due to the need to control sensors, injectors and valves.

- Fuel pump. In most cases, the submersible option is used. It is a low power electric motor that is connected to a liquid pump. Lubrication is realized by fuel, and prolonged use of the vehicle with less than 5 liters of fuel can lead to the failure of the electric motor.

In short, an injector is a point supply of fuel through a nozzle. The electronic signal comes from the control unit. Despite the fact that the injector has a number of significant advantages over the carburetor, it has not been used for a long time. This was due to the technical complexity of the product, as well as the low maintainability of parts that failed. Currently, point injection systems have practically replaced the carburetor. Let's take a closer look at why the injector is so good and what are its features.

Features of fuel equipment

The car has always been the object of attention of environmentalists. Exhaust gases are released directly into the atmosphere, which is fraught with pollution. Diagnostics of the fuel system showed that the amount of emissions with incorrect mixture formation increases significantly. For this simple reason, it was decidedinstall a catalytic converter. However, this device showed good results only with a high-quality emulsion, and in the event of any deviations, its efficiency dropped significantly. It was decided to replace the carburetor with a more accurate injection system, which was the injector. The first options included a large number of mechanical components and, according to research, such a system became progressively worse as the vehicle was used. This was quite natural, as important components and working parts became contaminated and failed.

In order for the injection system to be able to correct itself, an electronic control unit (ECU) was created. Along with the built-in Lamba probe, which is located in front of the catalytic converter, this gave good performance. It is safe to say that fuel prices today are quite high, and the injector is good just because it allows you to save gasoline or diesel. In addition, there are the following pluses:

- Increased motor performance. In particular, increased power by 5-10%.

- Improve the dynamic performance of the vehicle. The injector is more sensitive to load changes and adjusts the composition of the emulsion on its own.

- Optimum fuel-air mixture reduces the amount and toxicity of exhaust gases.

- The injection system starts easily regardless of weather conditions, which is a significant advantage over carbureted engines.

Fuel injection system and its device

First of all, it is worth noting the fact that modern injection engines are equipped with nozzles, the number of which is equal to the number of cylinders. Between themselves, the nozzles are connected by a ramp. There, the fuel is contained under slight pressure, and it is created by an electrical device - a gasoline pump. The amount of injected fuel directly depends on the duration of the nozzle opening, which is determined by the control unit. For this, indicators are taken from various sensors that are installed throughout the vehicle. Now we will consider the main ones:

- Air flow sensor. Serves to determine the fullness of the cylinders with air. In the event of a breakdown, the readings are ignored, and tabular data are taken as the main indicators.

- Throttle position sensor reflects the load on the engine, which is due to throttle position, air cycling and engine speed.

- Refrigerant temperature sensor. With the help of this controller, the control of the electric fan and the correction of the fuel supply, as well as the ignition, are implemented. In the event of a malfunction, immediate diagnostics of the fuel system is not necessary. The temperature is taken depending on the duration of the internal combustion engine.

- The crankshaft (crankshaft) position sensor is needed to synchronize the system as a whole. The controller calculates not only the engine speed, but also its position at a certain point in time. Since it is a polar sensor, if it fails, further operation of the vehicle is not possible.

- Sensoroxygen is needed to determine the percentage of oxygen in gases emitted into the atmosphere. Information from this controller is transmitted to the ECU, which, depending on the readings, corrects the emulsion.

It is worth paying attention to the fact that not all vehicles with an injector are equipped with an oxygen sensor. Only those cars that are equipped with a catalytic converter with Euro-2 and Euro-3 toxicity standards have them.

Types of injection systems: single point injection

Currently, all systems are actively used. They are classified depending on the number of nozzles and the place of fuel supply. There are three injection systems in total:

- single point (single injection);

- multipoint (distribution);

- immediate.

First, let's look at single point injection systems. They were created immediately after the carburetor ones and were considered more advanced, but are now gradually losing their popularity due to many reasons. There are several undeniable advantages of such systems. The main ones are significant fuel savings. Given that fuel prices are rather high today, such an injector is relevant. Interestingly, this system contains somewhat less electronics, so it is more reliable and stable. When information from the sensors is transmitted to the control element, the injection parameters immediately change. It is very interesting that almost any carbureted engine can be converted to single-point injection without significantstructural changes. The main disadvantage of such systems is the low throttle response of the internal combustion engine, as well as the deposition of a significant amount of fuel on the collector walls, although this problem was also inherent in carburetor models.

Since there is only one nozzle in this case, it is located on the intake manifold in place of the carburetor. Since the nozzle was in a good place and was constantly under a stream of cold air, its reliability was at the highest level, and the design was extremely simple. Flushing the fuel system with single point injection did not take much time, since it was enough to blow out only one nozzle, but increased environmental requirements led to the development of other, more modern systems.

Multipoint injection systems

Distributed injection is considered more modern, complex and less reliable. In this case, each cylinder is equipped with an insulated nozzle, which is located in the intake manifold in close proximity to the intake valve. Therefore, the supply of the emulsion is carried out separately. As noted above, with such an injection, the power of the internal combustion engine can be increased up to 5-10%, which will be noticeable when driving on the road. Another interesting point: this fuel injection system is good because the nozzle is located very close to the intake valve. This minimizes fuel buildup on the manifold walls, resulting in significant fuel savings.

There are several typesmultipoint injection:

- Simultaneous - all nozzles open at the same time.

- Pair-parallel - opening of nozzles in pairs. One injector opens on the intake stroke and the other before the exhaust stroke. Currently, such a system is used only at the time of emergency start of the internal combustion engine in the event of a phase failure (crankshaft position sensor).

- Phased - each nozzle is controlled separately, and opens before the intake stroke.

In this case, the system is quite complex and relies entirely on the accuracy of the electronics. For example, flushing the fuel system will take much longer as each injector needs to be flushed. Now let's go ahead and look at another popular type of injection.

Direct injection

Injection cars with such systems can be considered the most environmentally friendly. The main goal of introducing this injection method is to improve the quality of the fuel mixture and slightly increase the efficiency of the vehicle engine. The main advantages of this solution are as follows:

- careful atomization of the emulsion;

- formation of a high quality mixture;

- effective use of emulsion at various stages of ICE operation.

Based on these advantages, we can say that such systems save fuel. This is especially noticeable when driving quietly in urban areas. If we compare two cars with the same engine size but different injection systems, for example, direct and multipoint, then noticeablythe best dynamic performance will be in the direct system. Exhaust gases are less toxic, and the taken liter capacity will be slightly higher due to air cooling and the fact that the pressure in the fuel system is slightly increased.

But you should pay attention to the sensitivity of direct injection systems to fuel quality. If we take into account the standards of Russia and Ukraine, then the sulfur content should not exceed 500 mg per 1 liter of fuel. At the same time, European standards imply the content of this element is 150, 50 and even 10 mg per liter of gasoline or diesel.

If we briefly consider this system, it looks like this: the nozzles are located in the cylinder head. Based on this, injection is carried out directly into the cylinders. It is worth noting that this injection system is suitable for many gasoline engines. As noted above, high pressure is used in the fuel system, under which the emulsion is supplied directly to the combustion chamber, bypassing the intake manifold.

Fuel injection system: lean running

A little higher we examined direct injection, which was first used on Mitsubishi cars, which had the abbreviation GDI. Let's take a quick look at one of the main modes - lean mixture operation. Its essence lies in the fact that the vehicle in this case operates at light loads and moderate speeds up to 120 kilometers per hour. Fuel injection is carried out by a torch infinal stage of compression. Reflected from the piston, the fuel mixes with air and enters the spark plug area. It turns out that the mixture in the chamber is significantly depleted, however, its charge in the area of the spark plug can be considered optimal. This is enough to ignite it, after which the rest of the emulsion also ignites. In fact, such a fuel injection system ensures the normal operation of the internal combustion engine even at an air / fuel ratio of 40: 1.

This is a very efficient approach that saves a lot of fuel. But it is worth paying attention to the fact that the issue of neutralizing exhaust gases has become acute. The fact is that the catalyst is inefficient, since nitrogen oxide is formed. In this case, exhaust gas recirculation is used. A special ERG system allows you to dilute the emulsion with exhaust gases. This somewhat lowers the combustion temperature and neutralizes the formation of oxides. However, this approach will not allow you to increase the load on the engine. To partially resolve the problem, a storage catalyst is used. The latter is extremely sensitive to fuels with a high sulfur content. For this reason, periodic inspection of the fuel system is required.

Homogeneous mixing and 2-stage operation

Power Mode (Homogeneous Mixing) - ideal for aggressive driving in urban areas, overtaking, as well as driving on highways and highways. In this case, a conical torch is used, which is less economical than the previous version. Injectionis carried out on the intake stroke, and the resulting emulsion usually has a ratio of 14.7:1, that is, close to stoichiometric. In fact, this automatic fuel supply system is exactly the same as the distribution one.

Two-stage mode implies fuel injection on the compression stroke, as well as start-up. The main task is a sharp increase in the engine. A striking example of the effective operation of such a system is movement at low speeds and a sharp press on the accelerator. In this case, the probability of detonation increases significantly. For this simple reason, instead of one stage, injection takes place in two.

In the first stage, a small amount of fuel is injected on the intake stroke. This allows you to slightly lower the temperature of the air in the cylinder. We can say that the cylinder will contain an extra-lean mixture in a ratio of 60: 1, therefore, detonation is impossible as such. At the final stage of the compression stroke, a fuel jet is injected, which brings the emulsion to a rich one in a ratio of approximately 12:1. Today we can say that such an engine fuel system was introduced only for vehicles of the European market. This is due to the fact that high speeds are not inherent in Japan, therefore, there are no high loads on the engine. In Europe, there are a large number of highways and autobahns, so drivers are used to driving fast, and this is a big load on the internal combustion engine.

Something else interesting

It is worth paying attention to the fact that, unlike carburetor systems, injection requires that there be a regular check of the fuel system. This is due to the fact that a large number of complex electronics can fail. As a result, this will lead to undesirable consequences. For example, excess air in the fuel system will lead to a violation of the emulsion composition and an incorrect mixture ratio. In the future, this affects the engine, unstable operation appears, controllers fail, etc. In fact, the injector is a complex system that determines when a spark needs to be applied to the cylinders, how to deliver a high-quality mixture to the cylinder block or intake manifold, when to open the injectors and what ratio of air and gasoline should be in the emulsion. All these factors affect the synchronized operation of the fuel system. The interesting thing is that without most of the controllers, the machine can work properly without significant deviations, as there are emergency records and tables that will be used.

The efficiency of the internal combustion engine in our case is determined by how correct the data received from the controllers will be. The more accurate they are, the less possible various malfunctions of the fuel system. The speed of the system as a whole also plays an important role. Unlike carburetors, manual adjustment is not required here, and this eliminates errors during calibration work. Consequently, we will get a more complete combustion of the mixture and a better system in terms of ecology.

Conclusion

In conclusion, it is worth telling a little about the shortcomings that are inherent in injection systems. The main disadvantage is the high cost of internal combustion engines. Byby and large, the cost of such units will be higher by about 15%, which is significant. But there are other downsides as well. For example, a failed fuel system valve in most cases cannot be repaired, due to a leak, so you just need to change it. This also applies to the maintainability of equipment in general. Some components and parts are much easier to buy new than to spend money on their repair. This quality is not inherent in carburetor vehicles, where you can sort out all the important components and restore their performance without spending a lot of time and effort. Without any doubt, the electronic fuel supply system is being repaired with great effort and means. Sophisticated electronics are unlikely to be repaired at the first available service station.

Well, we talked with you about what injection systems are. As you can see, this is a very interesting topic for conversation. You can talk a lot more about what good nozzles and the ability to instantly adjust the engine. But we have already talked about the main points. Remember that the fuel system of a gasoline engine should be regularly inspected for possible defects. For example, due to the low quality of fuel, which is actually inherent in our country, nozzles often become clogged. Because of this, the engine starts to work intermittently, power drops, the mixture becomes too lean, or vice versa. All this has a very bad effect on the car as a whole, so constant and regular monitoring is needed. In addition, try to fill up only with the gasoline recommended by the manufacturer of your vehicle.

Recommended:

Types of brake systems, device and principle of operation

It is impossible to operate cars safely without brake systems. In addition to the main task (namely, stopping the vehicle), the braking system is designed to slightly reduce speed and hold the car in place. Depending on the purpose, as well as to improve safety, a modern car has several such systems. Also, in different cars, the brakes may have their own type of drive

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

Carburetor and injector: difference, similarities, advantages and disadvantages of carburetor and injection engines, principle of operation and expert reviews

For more than a hundred years, the car has firmly established itself in our lives. During this time, managed to become a familiar, everyday means of transportation. Let's see what the difference is between a carburetor and an injector, what advantages and disadvantages they have

Schemes of engine cooling systems, principle of operation

Schemes of engine cooling systems are almost identical. Modern cars use a hybrid system. Yes, it is, because not only liquid, but also air is involved in cooling. They blow the radiator cells. This makes cooling much more efficient