2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

In an internal combustion engine, a connecting rod is a part of a crank mechanism. The element connects the pistons to the crankshaft. Connecting rods are needed to transmit the translational movements of the pistons and turn these movements into rotation of the crankshaft. As a result, the car can move.

Design

We already roughly know what a connecting rod is, and now we will consider the design features. The part connects the piston to the crankshaft. In the process of work, very complex movements are made. The upper head of the connecting rod performs reciprocating movements, the lower part makes circular. The connecting rods take very high loads during operation, and this is taken into account in the design. See the diagram for the engine connecting rod.

The element consists of an upper head, a lower head, as well as a power rod that serves as a connector. The part is almost completely solid and is made of steel, cast iron, aluminum alloys.

Top head

The top end of the connecting rod is the part that has the hole for the piston pin. In this hole after installing the pistonpress the finger. The top head is one piece. Its shape is completely determined by how the piston pins are mounted.

If the pin is fixed, then the hole in the head on the connecting rod will have a cylindrical shape. The hole is made very precisely to ensure the correct tightness when connecting. Preload is when the size of the piston pin is slightly larger than the size of the hole in the connecting rod head. If the finger has a floating design. Then bimetallic or bronze bushings are pressed into the connecting rod head.

But there are also models of internal combustion engines with a floating type of finger, where there are no bushings, and the finger can rotate freely in the hole of the connecting rod head, because the hole in the head is made with a gap. In this case, oil must be supplied to the piston pin. The upper head is made in the form of a trapezoid, as it experiences enormous loads. The trapezoid allows you to increase the support during the operation of the pistons.

Lower head

It is connected via a detachable connection to the connecting rod journal on the crankshaft. The part consists of two parts - the upper part and the cover. The upper part is a single unit with the connecting rod. At the factory, the hole in the lower head is bored together with the cover, each of them can only be used with its own connecting rod. The cap and connecting rod are bolted together.

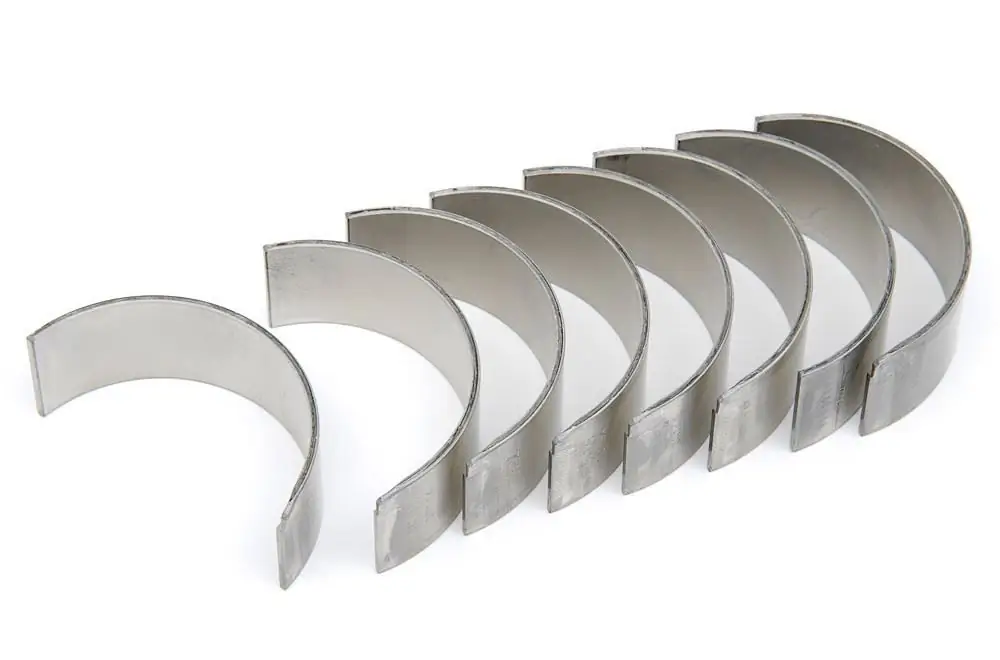

There are plain bearings at the bottom. These are details that are reminiscent of root bearings in design. They are also made of anti-friction coated steel band.

Rod

For most mass market engines, the stem has an extension to the lower head and is made in the form of an I-shaped. In diesel engines, the connecting rod is made more durable and massive, unlike gasoline engines.

Some motors can be equipped with connecting rods and other shapes. Typically, the rod has an internal channel for supplying lubricant to the head. Sometimes this channel also goes to the lower head of the connecting rod - this is the channel for supplying oil to the liners.

Materials

To reduce vibration and noise as much as possible, as well as to increase power, engineers develop connecting rods and other elements of an auto engine of maximum light weight. However, constant lightening leads to a decrease in strength characteristics. But the connecting rod is a part that experiences huge loads. The element must have a certain margin of safety.

To save money and to reduce the cost of production, products for internal combustion engines are made mainly of cast iron. This approach is perfectly applied to gasoline engines. Cast iron is the perfect compromise between price and durability.

As for diesels, all parts here work under even more serious loads. Therefore, cast iron is inappropriate here. Connecting rods for diesel internal combustion engines are produced by stamping and hot forging. The material in this case is special alloy steels. A connecting rod made by forging is much stronger than cast iron products. But the price is much higher.

How does it work?

We already know what the connecting rod looks like. How it works, we will find out further. the main taskelement - to take over the transfer of traction from the pistons moving forward to the crankshaft. Thus, thrust is converted into rotational movements. The transformation process is very fast.

When the piston is at TDC or slightly below it, the fuel mixture ignites and the piston is pushed down. The connecting rod connected to the piston will also move down, causing the crankshaft to rotate. When the engine piston reaches bottom dead center, due to the force of inertia, the crankshaft will push the connecting rod and piston up. This process is cyclic and repeats many times.

Conclusion

So, we learned what a connecting rod is. This is a part for connecting the pistons and the crankshaft. The mechanism is quite strong and performs an important function in the operation of the internal combustion engine.

Recommended:

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

What is a connecting rod bearing? Main and connecting rod bearings

The crankshaft of the engine is a body of rotation. He rotates in special beds. Plain bearings are used to support it and facilitate rotation. They are made of metal with a special anti-friction coating in the form of a half ring with precise geometry. The connecting rod bearing works like a plain bearing for the connecting rod, which pushes the crankshaft. Let's take a closer look at these details

Snowmobile for fishing: rating of the best, necessary functions and technical characteristics of models

A specific means of transportation for fishermen in winter is a snowmobile. Its use allows for a quick change of location, as well as transporting a significant amount of a variety of fishing equipment. The undeniable advantages of this type of equipment include ease of operation and uncomplicated maintenance

MTLB all-terrain vehicle: specifications, functions and photos

MTLB all-terrain vehicle: specifications, features, purpose, operating conditions, photo. MTLB all-terrain vehicle: description, driver work. parameters, functions, creation history. Work on a rotational basis as a driver of the MTLB all-terrain vehicle

MTLBU: specifications, all-terrain vehicle functions, engine description, photo

MTLBU: specifications, features of the operation of the all-terrain vehicle, photo. Engine description, general parameters, functions, modifications. The history of the creation of the MTLBU all-terrain vehicle: interesting facts. What is an MTLBU tractor?