2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

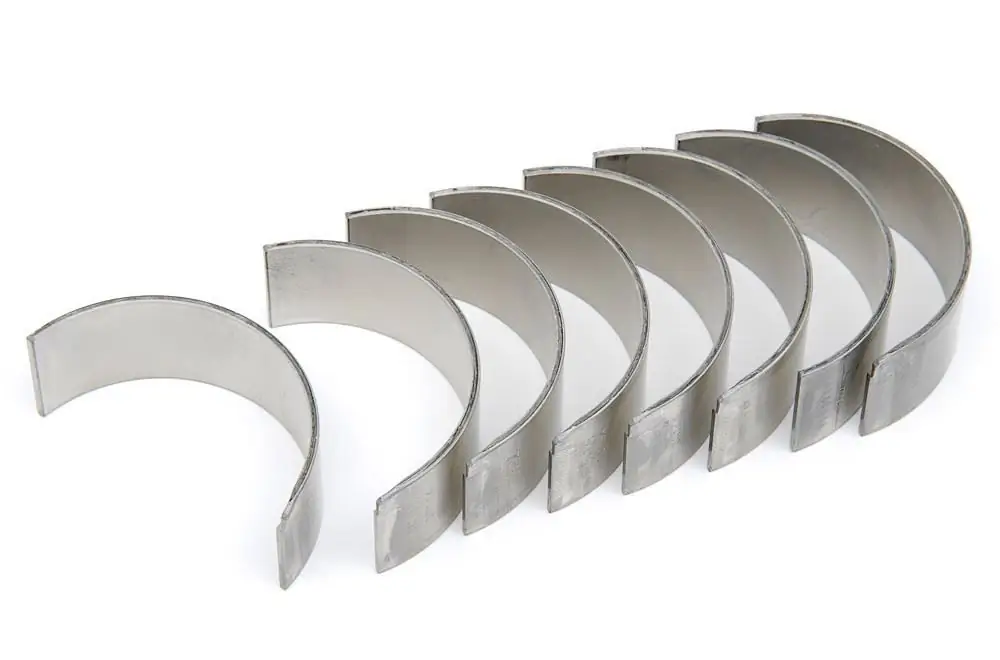

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail.

General Description

The connecting rod bearing (aka bushing) is a plain bearing. It is installed in the lower head of the connecting rod and covers the neck of the crankshaft. The part consists of two semi-rings made of steel with a special coating - it reduces friction. Half rings have grooves for lubrication, and one half ring hasthere is a hole for oil supply.

The connecting rod bearing does not have direct contact with the crankshaft journal. Parts rub in a special hydrodynamic mode due to the oil film formed in the gap between the shaft journal and the bearing.

Working conditions for engine liners

Due to the formation of an oil film, local concentration of loads is prevented. But if certain conditions are created, then the hydrodynamic regime normal for the bearing will be changed to mixed. This can happen if there is insufficient oil pressure in the engine, the assembly experiences huge loads, the oil viscosity is low, the lubricant overheats, and there is increased roughness on the shaft and bearing surface. Also, mixed mode can occur due to dirty oil, deformation and geometrical defects of the bearings.

In this mixed mode, the connecting rod bearing may come into contact with the surface of the crankshaft journal, which may subsequently cause scuffing, increased wear, sintering of the shaft with the bearing.

Materials and their characteristics

Materials for the manufacture of these parts must have a lot of sometimes conflicting characteristics and properties. In general, the material determines the reliability and quality of the bearing. The difference between different models is in the material and anti-friction coating.

So, the material must have sufficient fatigue strength - these are the maximum cyclic loads that the element can withstand for an unlimited number of cycles. If aexceed this load, then cracks will begin to appear due to metal fatigue.

Another important property is the resistance of the material to setting. This is the ability of the material for the main and connecting rod bearings to resist fusing to the metal of the shaft during direct contact.

Wear resistance is the property of a material to maintain its geometric dimensions, despite the presence of abrasives in the lubricant, as well as subject to direct contact with the crankshaft. The material must be workable. This means that the bearing must compensate for minor imperfections in the crankshaft and connecting rod seat through localized wear or deformation. The material must have the ability to capture the abrasive and dirt that circulates in the oil. Another important quality is corrosion resistance.

Long and reliable operation of connecting rod bearings of engines is achieved only by combining high-strength material with softness by specialists. The liner should be both soft and hard at the same time. It may seem paradoxical, but modern products combine all these characteristics.

Bearing device

In fact, the material from which these parts are made is much more important than geometric characteristics. The plain bearing is made up of several layers. Bimetallic elements and trimetallic elements can be distinguished.

Bimetal insert

The connecting rod bearing shells are made of steel base. Steel provides the details neededstiffness as well as tightness.

Next comes the second layer - anti-friction coating. It is quite thick - the thickness is 0.3 millimeters. The thickness of this layer is very important for the bearing. It can be run in even to large shaft defects. The bearing has high absorption properties. The composition of the anti-friction layer is from six to twenty percent tin, as well as from two to four percent silicon. The alloy may also contain elements such as nickel, copper, manganese, vanadium.

Tri-metal liner

Here, in addition to the steel base, there is also an intermediate copper layer - it contains, in addition to copper, up to 25% lead and up to 5% tin. Anti-friction coating is made of an alloy based on lead and tin. The coating is not thick - about 20 microns. This thickness gives fatigue strength, but the anti-friction properties are reduced. Also, between the main and intermediate layers, the liner is covered with nickel - the thickness is no more than 2 microns.

Features of operation

During operation, the connecting rod bearing wears out, and this is the first reason why it is changed. No matter how hard the car owner tries to save these elements, the laws of physics take their toll, and this cannot be avoided. The anti-friction layer is erased, the crankshaft has free play, the oil pressure and the amount of lubricant are reduced. As a result, breakdowns occur due to increased friction.

Another situation is turning the liners. This is also a reason to replace. Insertjust sticks to the crankshaft journal. The engine stalls. Causes include heavy grease with lots of debris, lack of oil, improper connecting rod bearing torques.

Conclusion

As you can see, liners are small but very important parts for trouble-free operation of the engine. Without them, the engine would simply not work. These are technological products capable of withstanding high loads, high temperatures and exorbitant speeds. And it is precisely because of the presence of liners in the engine that you need to change the oil more often - dirt kills bearings. The elements themselves are not so expensive, but to replace them you need to completely disassemble the engine. This job is not easy, requiring knowledge, experience and a lot of time.

Recommended:

A connecting rod is Functions, features of a connecting rod

In an internal combustion engine, a connecting rod is a part of a crank mechanism. The element connects the pistons to the crankshaft. Connecting rods are needed to transmit the translational movements of the pistons and turn these movements into rotation of the crankshaft. As a result, the car can drive

What is a connecting rod bearing? Main and connecting rod bearings

The crankshaft of the engine is a body of rotation. He rotates in special beds. Plain bearings are used to support it and facilitate rotation. They are made of metal with a special anti-friction coating in the form of a half ring with precise geometry. The connecting rod bearing works like a plain bearing for the connecting rod, which pushes the crankshaft. Let's take a closer look at these details

Engine gas distribution mechanism: device, principle of operation, purpose, maintenance and repair

Timing belt is one of the most critical and complex components in a car. The gas distribution mechanism controls the intake and exhaust valves of an internal combustion engine. On the intake stroke, the timing belt opens the intake valve, allowing air and gasoline to enter the combustion chamber. On the exhaust stroke, the exhaust valve opens and exhaust gases are removed. Let's take a closer look at the device, the principle of operation, typical breakdowns and much more

Purpose, features of the device and the principle of operation of the car starter

As you know, to start a car engine, you need to turn the crankshaft several times. On the first machines, this was done manually. But now all cars are equipped with starters that allow you to rotate the shaft without any effort. The driver only needs to insert the key into the lock and turn it to the third position. Then the motor will start without problems. What is this element, what is the purpose and principle of operation of the starter? We will talk about this in our today's article

Exhaust system VAZ-2109: purpose, device, technical characteristics, features of operation and repair

VAZ-2109 is perhaps the most famous Russian-made car. This car has been produced since the days of the USSR. It was the first car where the torque was transmitted to the front rather than the rear wheels. The car is very different in design from the usual "classics"