2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

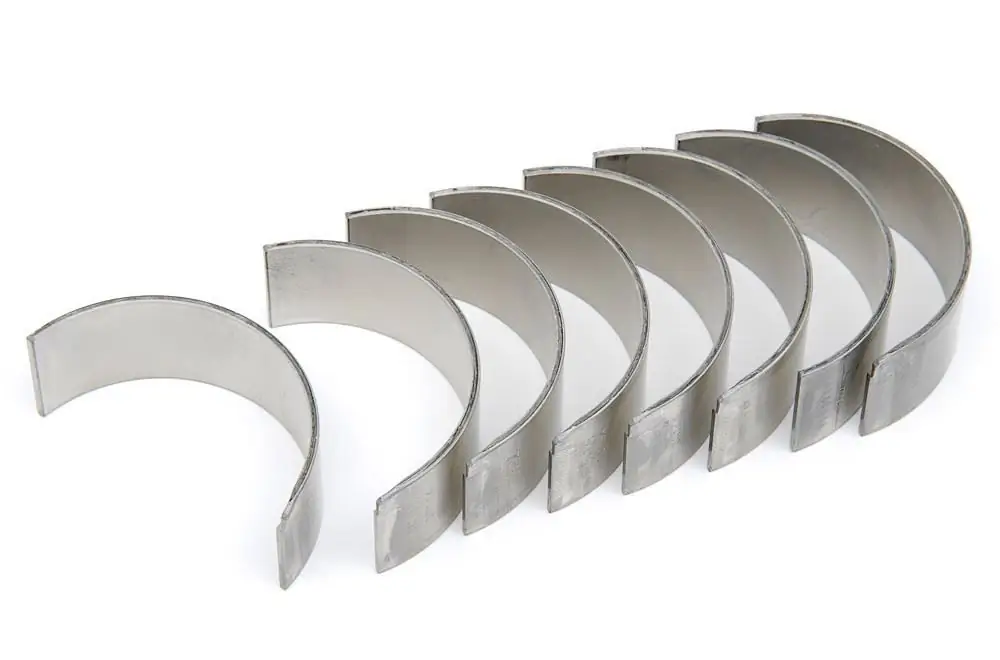

The crankshaft of the engine is a body of rotation. He rotates in special beds. Plain bearings are used to support it and facilitate rotation. They are made of metal with a special anti-friction coating in the form of a half ring with precise geometry. The connecting rod bearing works like a plain bearing for the connecting rod, which pushes the crankshaft. Let's take a closer look at these details.

Functions

Rotation parts in the device of the internal combustion engine are equipped with plain bearings. They perform various tasks.

So, the main bearings are needed to support the crankshaft and facilitate its rotation. These parts are installed inside the cylinder block. Each part is a half ring, and the insert consists of two halves. The inner surface has a groove - it is through it that the lubricant enters. There is also a hole in the body of the liner - it is necessary to supply oil tocrankshaft journals.

A connecting rod bushing is required to ensure the rotation of the connecting rod neck. The latter, when the engine is running, causes the crankshaft to rotate. These elements are installed in the lower head of the connecting rods.

You can also highlight the thrust rings of the crankshaft - they are designed to prevent axial movement of the crankshaft. Very often, on different engine models, the thrust ring is part of the main bearing. Such a combined part has a special name - a shoulder or flange insert.

The bushings mounted in the top head on the connecting rod are designed to provide room for the piston pin. It connects the connecting rod and piston. Available in the internal combustion engine and camshaft liners. They are responsible for supporting and rotating the camshaft. Details can be seen at the top of the cylinder head or in the cylinder block where the camshaft is located at the bottom.

Internal and connecting rod bearings are constantly lubricated with oil during operation - it is supplied through the technological holes to the friction surfaces. This ensures hydrodynamic friction. There is no contact between the rubbing parts due to the oil film between the surface of the liner and the working surface of the shaft.

Design Features

The plain bearings in the internal combustion engine are composite and consist of two flat half rings that completely cover the crankshaft. The part has several elements - this is one or two holes for supplying oil to the lubrication channels, locks for fixing the liner in the bed, a groove for lubrication.

Connecting rod bearing representsis a multilayer structure. The basis is a steel plate with a special coating. It is thanks to this anti-friction layer that friction is reduced. The coating is often made of soft materials and may consist of several layers. The liner is coated on top with a material of lesser softness, and thanks to this coating, the part absorbs wear particles of the crankshaft, jamming and the formation of scoring and other defects are prevented. Structurally, connecting rod and main bearings can be divided into bimetallic and trimetallic.

Bimetallic

Bimetallic liners are considered the simplest. It is based on a steel plate - its thickness is on different models of internal combustion engines from 0.9 mm to 4 mm. The main bearing is always thicker, the connecting rod is thicker. An anti-friction coating is applied to the plate - its thickness ranges from 0.25 mm to 0.4 mm. The layer is made of copper-lead-tin, copper-aluminum, copper-aluminum-tin and other soft alloys. Aluminum and copper in these alloys contains about 75%. The rest is tin, nickel, cadmium, zinc.

In bimetallic liners, the thickness of the anti-friction coating is a very important property. They can be run in and adapted even to large geometrical defects. The bearing has good adsorption capacity.

Trimetallic

In trimetallic connecting rod bearings, in addition to anti-friction coating, there is also a third layer. Its thickness is very small - only 0.012-0.025 mm. It provides protectivepart properties and improves anti-friction characteristics. The coating is most often made of a lead-copper-tin alloy.

Most often lead in such alloys contains up to 90%. Tin improves corrosion resistance. Copper is needed to harden the coating. Due to the low thickness of the coating, the fatigue strength increases, but the anti-friction characteristics decrease. This is especially noticeable if the soft cover is worn.

Geometry

Naturally, the sizes of connecting rod bearings for different internal combustion engines are different. The most basic parameter is the oil clearance. It is equal to the difference between the inner diameter of the bushing and the diameter of the shaft. Also an important indicator is the size of the oil clearance. If the gap is very large, then the oil flow increases, which reduces the heating of the bearing. But oil also introduces a non-uniform load distribution, which increases the likelihood of bearing failure due to fatigue. A large gap will cause running noise and vibration. A small gap will cause the engine oil to overheat and reduce viscosity.

The landing interference is needed to ensure a secure fit of the VAZ connecting rod bearing in its socket. Securely and firmly seated bearings are evenly in contact with the surface of the seat - this will prevent the bearings from moving during operation. It also ensures efficient heat dissipation.

Reason for replacement

Indications for replacing connecting rod bearings are their wear. It can be identified by characteristic features. We will consider the most popular causes of malfunctions,wear, failure.

Foreign bodies in liners

A sign of dirt ingress will be local damage to the part - defects on the working surface. Sometimes minor damage occurs on the reverse side. Debris on the surface is the first cause of further wear. Can only be fixed by replacement.

Mud erosion

Scoring on the surface, as well as inclusions of dirt, will be a sign of this malfunction. In severe cases, erosion moves to the region of the lubrication hole. Among the reasons in the first place is bad oil with dirt or abrasive impurities.

Metal fatigue

This can be caused not only by operation longer than necessary, but also by high loads on the KamAZ connecting rod bearings. Signs include torn metal particles from the body of the liner, especially in places where the load is very high.

When operating the engine on low-quality liners, there is a risk of severe overload. The force moves to the edges of the parts. To eliminate the malfunction and diagnose it, check the axial shape of the crankshaft journal, the geometry of the liner bearings. In this case, it makes sense to install a quality liner.

Recommended:

A connecting rod is Functions, features of a connecting rod

In an internal combustion engine, a connecting rod is a part of a crank mechanism. The element connects the pistons to the crankshaft. Connecting rods are needed to transmit the translational movements of the pistons and turn these movements into rotation of the crankshaft. As a result, the car can drive

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

Support bearings of the front struts: photo, signs of malfunction. How to replace the front strut bearing?

Information about what constitutes the support bearings of the front struts. The design, principle of operation are described, as well as instructions for replacing these suspension elements

Grease for high-speed bearings: description, characteristics and composition

It's no secret that proper and regular maintenance of bearings provides a significant extension of the service life of this element, which is an integral part of the entire automotive mechanism. Let us further consider the features of the products used as lubricants for bearings, as well as their varieties and correct use

PTF VAZ-2110: connecting foglights, installation and expert advice

Not all "tens" cars have factory-installed foglights (PTF). You can connect the PTF to the VAZ-2110 yourself if you carefully study the instructions and know the sequence of work. This will be discussed in the article