2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

On the cardan shaft in the car is an important structural element called "outboard bearing". It is necessary to maintain the correct position of the cardan shaft and axis, as well as to perceive and transfer the load, both axial and radial. Such a product provides rolling, rotation and linear movement along the axis, produced with the least resistance.

Outboard bearing structurally consists of a metal housing with a hole in it, into which the sleeve is inserted. The gap formed between them is filled with a lubricant, which allows easy movement of the main parts relative to each other. This significantly reduces the friction of the elements against each other, reduces the amount of thermal conductivity, protects against negative environmental influences, and also improves the reliability and efficiency of the mechanism.

Main operational featuresand design advantages that an outboard bearing has:

- vibration resistance;

- silence;

- capable of working with significant radial and angular loads;

- effective protection against aggressive environments;

- easy to repair.

The first signs of a malfunction are considered to be a strong blow to the body, which can be felt through the seat, some time after that, a hum and vibration may appear. The most common problem is aging and wear of the gum. In this case, you should immediately contact a car service, since the replacement of the outboard bearing is possible only when the entire driveshaft is removed.

The following are some guidelines for choosing and purchasing this part.

1. If possible, purchase bearings in specialized car dealerships that guarantee the availability of high-quality and new equipment. Because when you buy a used item, you can't even guess how long it will last, so you can't tell when it will fail if installed in your car.

2. Choose only original parts that match your machine. If the required model is no longer in production, then you should contact the manufacturer. In such cases, she gives some guidance and gives an example of a replacement that is as close as possible to the original design.

3. Check for sufficient lubricant. The outboard bearing may already have been filled with grease.material at the factory, but could be produced "dry". In the first case, immediate installation is possible, in the second, some additional steps must be taken to fill the bearing with grease. These activities are not complex and are often described on the product label or packaging.

4. When buying, identify the absence of play. It is believed that the presence of backlash on a new bearing is a manufacturing defect, and low-quality products are screened out at the factory. However, no one is immune from mistakes. Therefore, immediately check the integrity and serviceability of the purchased structure with the seller.

The outboard bearing is an integral part of the cardan shaft, therefore the service life of this part of the structure directly depends on the nature of the operation of the vehicle as a whole.

Recommended:

Connecting rod bearing: device, purpose, specifications, features of operation and repair

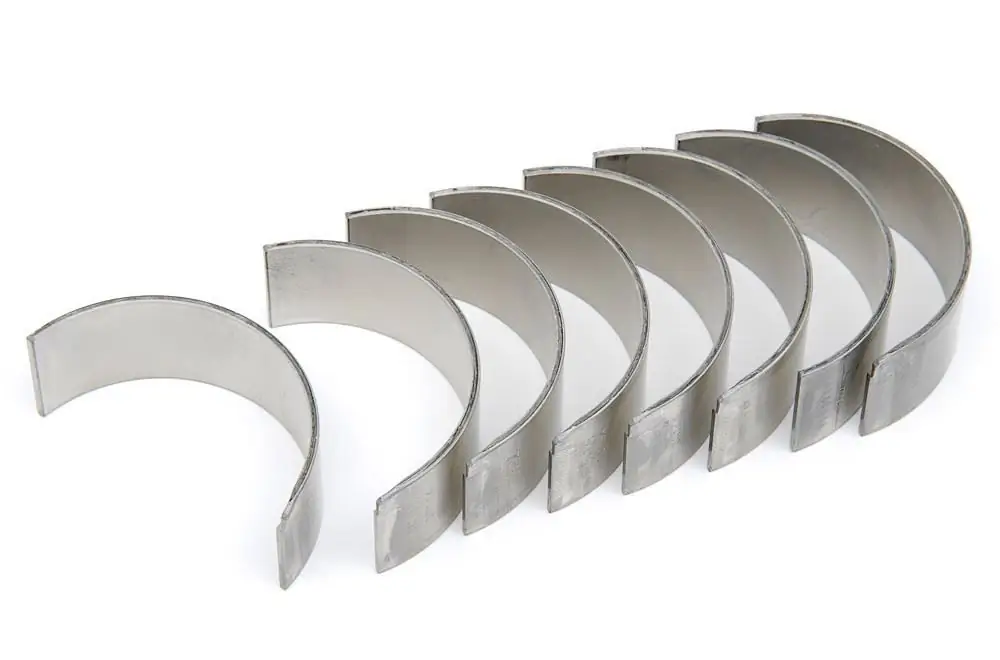

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

What is a connecting rod bearing? Main and connecting rod bearings

The crankshaft of the engine is a body of rotation. He rotates in special beds. Plain bearings are used to support it and facilitate rotation. They are made of metal with a special anti-friction coating in the form of a half ring with precise geometry. The connecting rod bearing works like a plain bearing for the connecting rod, which pushes the crankshaft. Let's take a closer look at these details

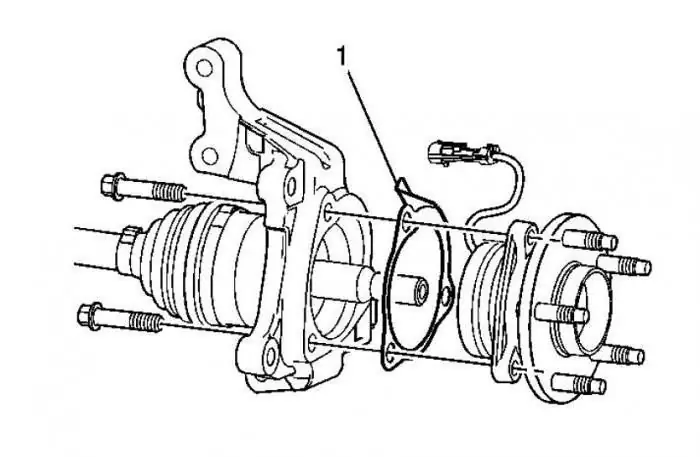

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Thrust bearing: design, meaning, replacement

Thrust bearing is a small but extremely important part in a car. What is it and why is it needed, it is worth discussing in detail

Front hub design and do-it-yourself bearing replacement

The front hub ensures the wheels turn and rotate around their own axis. This is typical for any car, regardless of the type of drive - front or rear. The only thing that is present in the hubs of cars with front-wheel drive is more powerful bearings, since a CV joint is installed on them