2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Only premium cars have really high-quality sound insulation. The rest are quieted rather mediocrely, if they paid attention to this moment at all at the factory. However, soundproofing a car with your own hands is not so difficult. True, it will take a lot of effort, free time and materials. But first things first.

Full or local noise isolation

Automotive manufacturers are struggling with extraneous noise during the development of the car body. It is the framework that plays the decisive role. Therefore, there are places where the sound from the outside breaks through more or less. For example, wheel arches can be considered a sore spot for many modern cars. The sound from the roadway freely enters the interior of the car. You can solve the problem by installing the correct "Shumka". Before you wonder how to make a car soundproofing with your own hands,We need to find the weakest points. Perhaps they should be de alt with first of all.

Many experts recommend performing only comprehensive noise reduction of the vehicle. After all, it is this approach that allows you to eliminate from 30 to 70% of extraneous noise. True, such a solution to the problem cannot always be called correct. For example, if a car has a decent “shumka”, but the sound quality of the audio system does not suit you, then it is not at all necessary to process the car completely. Often it is enough to deal with doors and arches, the result will be noticeable right there. Well, now let's consider this issue in more detail, get acquainted with the basic concepts and technology for performing work.

Brief overview of popular materials

Before you make a car soundproofing with your own hands, you need to deal with the products on the market. After all, you need to know what you are buying and whether it is really worth it. It’s worth starting with vibration-absorbing materials:

- Vibroplast (Silver) is a rather elastic and flexible material. The sheet is marked with 5 x 5 cm squares, which allows you to cut it to the desired size. Vibroplast perfectly copes with the function of a sealant and protects the body from corrosion, and it also does not absorb moisture. The thickness of this material is only 2 mm, a square meter of vibroplast weighs about 3 kilograms. Suitable for installation on doors, hood or trunk.

- Vibroplast (Gold) - differs from the above only in weight and thickness (4 kg per square and 2.3 mm). It must be understood that the thicker the vibration isolation, the more difficult the installation.

- Bimast (bombs) is the best choice for quality audio preparation. It has the highest efficiency due to the multi-layer construction. The first layer is made of bitumen, the second - rubber. The thickness of the sheet is 4.3 mm, and the weight is 6 kilograms per square meter. During installation, it is necessary to warm up to 50 degrees.

Do-it-yourself car soundproofing: materials (splenitis, accent, bitoplast)

If the above brands are vibration-absorbing materials, then Splen 3004 is sound-absorbing. In addition, it has good thermal insulation characteristics. Operating temperature from -40 to +70 degrees Celsius. It is noteworthy that this material does not absorb moisture and does not collapse under the influence of direct sunlight. Splenitis 3004 is 4 mm thick and weighs only 0.42 kilograms per square meter. The manufacturer also presents models 3002 and 3008 with a thickness of 2 and 8 mm, respectively.

Splenitis is glued to vibration-absorbing material. Usually the most problematic areas are treated with the thickest sheets and vice versa. Ideal for wheel arches and other noisy areas of the car. It is not recommended to apply at temperatures below +10, as the adhesive properties deteriorate significantly. Materials such as accent-10 and bitoplast-5 are also popular among motorists. The latter absorbs up to 90% of noise.

Make car soundproofing with your own hands

It is recommended to start with the simplest and most easily accessible body parts. These can be considered the hood and trunk. Immediately worth itnote that getting rid of the noise of a running motor will not work. In the cabin, all the noise will remain at the same level. But the thermal insulation properties will improve significantly, which is especially important for the winter period. Often there is regular thermal insulation. It should not be thrown away, but it must be dismantled for the duration of the work. The working surface must be thoroughly degreased before gluing. White spirit is perfect. As a base, it is better to use accent-10. It retains heat well and does not light up under the influence of high temperatures. On top of it, you can stick a vibroplast ("Silver").

It is extremely important to choose the right thickness of materials and their weight. Too heavy a hood will significantly reduce the life of shock absorbers or hinges that are not designed for such loads. As for the thickness, the lid may not close corny. All of these rules and materials apply to the trunk as well.

Working with car doors

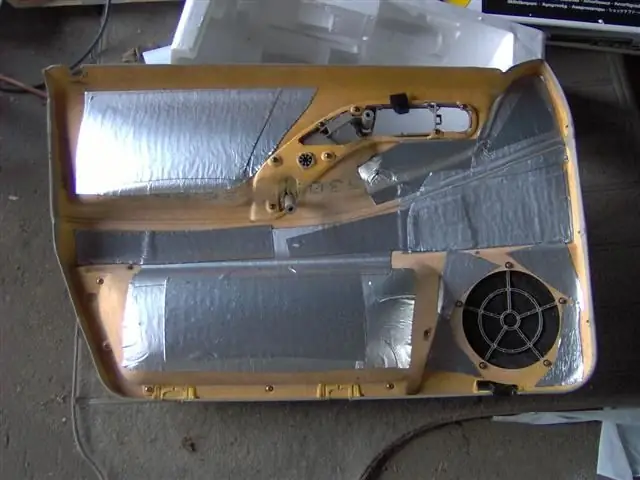

Doors are one of those areas that need to be addressed in order to achieve high-quality sound from a car audio system. A lot of noise also passes through them, especially if there is no regular "Shumka".

The thinner the metal of the door, the more soundproofing will be required to achieve good results. Vibroplast ("Silver", "Gold"), which is glued opposite the column, is suitable as a material. It is desirable to cover about 80% of the area. As with the hood, it is recommended to monitor the weight. BetterDo not overload the doors as this will cause the hinges to sag and need to be replaced.

If it is necessary to achieve not only silence in the cabin, but also high-quality sound of the audio system, it is recommended to make "Shumkov" in several layers. First vibroplast, and then splenitis. Technological openings are best left open, as they are necessary for ventilation. If they are closed, then the corrosion process will soon begin. With rear doors, if there are no speakers, it is easier to work. This is due to the fact that the "Shumkov" there need an order of magnitude less.

Most labor-intensive work

A lot depends on the make of the car. But it is hardly possible to manage with small forces, whether it be Skoda or VAZ. Do-it-yourself soundproofing of the car (floor) takes a long time, since it is necessary to completely disassemble the interior, remove all seats and wiring from clips, but it's worth it.

The heaviest and most effective materials are usually used, such as bomb bimast and 8 mm splenitis. Working with thick sheets is not very convenient, so it is better to lay 2 layers of 4 mm splenitis than one layer of 8 mm. We try to cover the bottom as much as possible, preferably at least 80%. During work, it is necessary to use an industrial hair dryer for better adhesion of materials. It is also recommended to make marks at the points of fastening of clips for wiring braids, seats, etc. Before performing work, it is advisable to carefully treat the surface. Firstly, it is necessary to clean out the debris and remove the old sound insulation (if any), and secondly, do not forgetdegrease the surface. Work in a well-ventilated area and use a hairdryer.

Wheel arches and niches

Since it is not easy to do the soundproofing of a car with your own hands in a complex way and it will take a lot of time, it is best to do the work in stages. At the final stage, it is recommended to process wheel arches and niches. In most cars, these places suffer the most, so the "shumka" here will need a thick one.

Do-it-yourself soundproofing of car arches is quite quick and easy. Although there are still some nuances here. The first step is to put the car on a jack and remove the wheel, and then you need to dismantle the fender liner. The latter cannot be thrown away, since they also partially struggle with noise. The next step is to thoroughly clean the surface to be treated and degrease it. Then we apply vibroplast ("Gold"). In the case of wheel arches, it is better to choose a thicker material. Mounting it is inconvenient, but the result will be much better. In addition, it is worth treating the arches with anti-gravity. It will provide additional protection against noise and protect the body from corrosion.

What results should we expect?

It is impossible to answer this question unambiguously. Much depends on the brand of the car, the material used and the specialist who performed the work. For example, if you silence a good foreign car, you can eliminate no more than 20-30% of the noise. It's all about the base installed at the factory. But do-it-yourself soundproofing of car doors onVAZ will give really tangible results. If you approach the issue comprehensively, the amount of noise will decrease by 70%. This is a very good result, which will be immediately noticeable. If you additionally go through the anti-creak, then the "crickets" will disappear, which immediately after the "Shumka" will begin to beat on the ears.

A few rules when working with soundproofing

The first and most important thing to remember is that work is possible at a temperature of at least 10 degrees Celsius. The adhesive base must be additionally heated with a hairdryer. If this is not done, then the material may peel off after a while. For the best quality of work, you need to purchase a rolling roller. This simple tool allows you to completely remove air bubbles.

It is advisable to carry out work in a well-ventilated area, and if it is warm and dry outside, you can do it right there. Get plenty of clean rags, water, and a degreaser. If the insulation is foil, then gloves must be worn, as there is a high probability of getting cuts. For many beginners, their hands suffer very much, as they need to get to hard-to-reach places and cut a lot. The surface to be treated must be dry, clean and free from rust.

Is it worth saving?

Owners of domestic and Chinese car brands very often use budget soundproofing options. The thing is that an integrated approach using profile materials is not cheap. Some people can't afford these.costs, but others see no point in it. After all, most vibration-insulating materials for a car are analogues of building insulation, seals, etc. Is this really so? It makes sense.

Of course, you should not fall for the tricks of sellers and buy polyethylene, felt or splenitis. It is better to turn your attention to materials such as hydroisol and gerlen. If you follow the technology, the result will be worthy. It is not necessary to use expensive materials. With your own hands, the correct soundproofing of a car can be done not only with the help of expensive STP or bimast, but also with the same gerlen or waterproofing.

Entrust the work to "specialists" or do it yourself?

If the work is done by real craftsmen, it will not be cheap at all. But the result will exceed all expectations. But usually such a plan, specialists use expensive materials and take a lot of money for work. It is advisable to give a car away only if the car is expensive and belongs to the premium segment. "Zhiguli" can be made independently, because it does not require special training at all. Yes, and it will be possible to save not only on work, but also on materials.

Driver Reviews

Many car owners note tangible improvements after using soundproofing. Others are inclined to believe that it is necessary to deal with noise at a constructive level. Much still depends on the quality of the material used and its thickness and the appropriateness of the application inone place or another. This also applies to the technology of work. That is why there are both positive and negative reviews. Although the first is an order of magnitude more. But someone did not get the desired result, hence a certain opinion is formed.

Summarize

Here we are, in fact, de alt with this issue. As you can see, all the work can be done by hand. Soundproofing the wheel arches of a car, the bottom or doors is done on its own quite simply, but you must follow simple rules and pasting technology. You don’t need a lot of tools, just have a good stationery knife and a pair of blades, scissors and a building hair dryer. Another important point is intermediate drying in the absence of a self-adhesive layer. As for the disassembly and assembly of interior elements, you can download a special manual for your car.

Recommended:

How to polish scratches on a car with your own hands: technology and materials

Scratches on a car body are quite common. You can find them anywhere, unsuccessfully opening the door, parking too close to a bush, not noticing an obstacle, and in a number of other situations. In some cases, you can get rid of them only by resorting to painting in the cabin, in others, you can polish the scratches on the car with your own hands

Proper battery charging tips and tricks

In the first autumn cold, it is necessary to prepare the car for winter. Moreover, this operation includes not only the installation of a winter set of tires. An important aspect is the battery. After all, the quality of starting a car depends on its condition. If you check the battery in time, you can eliminate problems such as poor starting of the engine or a complete discharge of the battery

Proper break-in of a new car

A new car cannot be used in the same way as a high mileage car. The thing is that it has completely new components that have been assembled into a single system, and it needs preliminary grinding. Breaking in a new car is a simple and mandatory task for every car owner

Professional car polishing: tools and technology

Professional car body polishing: features, technology. Do-it-yourself professional car body polishing: recommendations, tools

How to store tires without rims in winter or summer? Proper storage of car tires without rims

Twice a year, cars are "changed shoes", and their owners are faced with the question: "How to store rubber?" This will be discussed in the article