2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Efficient braking is one of the components of safe driving. Most modern cars use a brake disc and caliper in their design. VAZ-2108 is no exception.

The situation when the car starts to stop skewed to one side due to the fault of this device is a frequent occurrence. The article will discuss the causes of uneven braking and troubleshooting methods.

What is the function of the caliper

In a brake system where the main component of braking is the disc, the caliper plays the role of the base on which the brake linings and the elements that actuate them are fixed.

While the car is moving, the pistons that push the pads are inside the caliper. A spring holds them in this position. When you press the brake pedal, hydraulic fluid begins to flow into the inside of the pistons. Those, in turn, push out the brake linings. Since they are located on both sides of the brake disc,begin to wrap around it tightly, while extinguishing the torque of the wheel, reducing the speed of the car.

The front calipers of the VAZ-2108 are rigidly fixed with 2 bolts on the steering knuckle. Therefore, they not only take on the braking force, but also transmit it to the chassis of the car.

Caliper device

In the family of front-wheel drive VAZ cars, disc brakes on the front axle, and, accordingly, calipers are installed only on them. At the rear are drum-type brakes.

The VAZ-2108 caliper is clearly visible if the steering wheel is turned all the way and the wheels are at an angle to the vehicle axis. It is also clearly visible with the front wheels removed. A massive part that fits the brake disc is the caliper. It consists of the following elements:

- Fixed metal brace. It plays the role of a frame on which the entire structure is assembled. Attaches to the steering knuckle.

- Moving brace. It moves relatively movable with connecting fingers that serve as guides.

- Working cylinder. It is an elongated part in which a hydraulic piston is placed. It is fixed on the movable bracket of the brake caliper-VAZ 2108. The working cylinder has a fitting for pumping and bleeding air. As well as connecting to the hydraulic brake system.

- Brake pads. With the help of cotter pins, they are fixed in the movable bracket.

In addition to the above details, there are severalbolts that serve to attach the caliper.

What problems occur

When the caliper-VAZ 2108 starts to malfunction, the character of the car's braking changes. She can go skidding instead of straight ahead. This is especially noticeable in winter - the car begins to turn when braking.

The next symptom is a master cylinder piston jammed in the working position. In this case, there will be a constant sound of rubbing brake linings and a very high temperature of the brake disc. Moreover, such a malfunction can lead to its deformation. This happens at the moment when a car with a hot brake disc drives into a puddle. A sharp temperature drop leads to warping of the surface. As a result, when braking, a beating begins to be felt. Your foot on the brake pedal will feel the impact.

There are two types of reasons leading to incorrect operation:

- Rust. Due to deep corrosion, the brake piston stops working normally. It either sticks in its original position, resulting in weak braking, or does not return to its original position, which causes the brake pads to constantly rub against the disc.

- Deformation of the caliper as a result of impact. In this case, the piston is stuck due to the incorrect position of the parts in the assembly unit.

In the case of corrosion, you can try to restore the characteristics using the VAZ-2108 caliper repair kit. Deformation resulting from an impact cannot be repaired- replacement parts only.

Restoring an old device

VAZ-2108 caliper works in difficult conditions. Constant dust and dirt flying from the wheels, freeze cycles in winter, lead to premature failure. However, the worst performing caliper can be restored.

First of all, you need to establish for sure that the problems with braking are caused by the caliper. To do this, you need to put the car on a jack and ask to press the brake pedal several times. At this point, you should watch how the brake linings move in the direction of the brake disc: is there any jamming, how freely do they return back. In this case, you can try to rotate the wheel, watching how it stops under the action of the brake. The fuzzy work of the overlays will be immediately noticeable. In addition, you can see the runout of the brake disc. If it has irregularities, then in addition to repairing the caliper, you need to grind the disk on a lathe. Otherwise, braking will remain ineffective.

Required tools for repair

To remove the brake caliper-VAZ 2108, and then disassemble and restore it, you will need the following tools and materials:

- Balloon wrench.

- Open-end wrenches or sockets with a knob for 8, 13, 15, socket wrench for 17.

- Internal torx for 15 or 16 bolt, wrench for removing brake hoses. It differs from the conventional open-end one in having a more complete coverage of the nut.

- Vise.

- Repair kit for calipers. Suitable for VAZ 2108 - 21099, VAZ 2113- 2115, Kalina, Grants. The only thing you need to pay attention to the diameter of the wheels. For VAZ-2108, a repair kit is needed for models with 13-inch wheels.

- New guide pins. Often, after operation, they have small deformations, as well as traces of deep corrosion, which prevents the floating bracket from moving freely. Therefore, it is better to replace.

- New bleeder fittings.

- Drill with wire nozzle for removing rust.

- Solvent, paint, corrosion converter, rags.

- Compressor. Not required, but preferred.

How to remove and disassemble the VAZ caliper

To dismantle the caliper, you need to hang the car on the jack, remove the front wheel. Then unscrew the nut connecting the flexible hose of the brake system to the brass tube. Brake fluid will leak out of the front circuit, so you should prepare a container for it in advance.

Using a 17 socket wrench or a socket wrench, unscrew the bolts that secure the caliper to the steering knuckle. They are located on the inside and are located next to the grenade boot.

Then, by sliding up the brake disc, the caliper can be completely removed. The rest of the dismantling work is carried out in a vice. If they are not available, then disassembly is done on the spot, without disconnecting the caliper from the steering knuckle.

Further dismantling

Clamping the caliper in a vice, unscrew the two bolts under the torx head, take out the guide pins. After that, the assembly unit is divided into three parts:caliper, brake cylinder and fixed caliper.

All these three parts must first be cleaned with a brush clamped in a drill. Then you need to proceed to the main part of the repair - restoring the mobility of the piston. To remove it from the brake cylinder, do the following:

- Use a flathead screwdriver to remove the retaining ring that secures the boot. Thanks to him, dirt does not get inside the mechanism.

- Remove boot of VAZ-2108 caliper.

- Remove the piston. Ideally, it is extracted using compressed air, which is fed into the brake fluid inlet. If the compressor is not available, then the piston is removed using pliers. It is necessary to apply efforts alternately to opposite sides so that there is no distortion that will make dismantling difficult.

- Remove the bleed screw.

- Remove the O-ring between the piston and cylinder walls.

Repair

After preliminary cleaning of the caliper parts, they must be degreased and painted. Before applying paint, all holes are sealed with masking tape. You need to paint in several layers. Parts can be etched with phosphoric acid before painting to completely eliminate any traces of corrosion left after brushing.

The removed piston of the VAZ-2108 caliper should be carefully inspected for scoring. Then you need to polish the interface of this part and the cylinder with water with sandpaper with a grit of 2000-3000.

After drying, the piston, lubricated with brake fluid, is installed in place. Along the way, a new bleeder valve is installed.

The repair kit contains new rubber seals, including rubber bands that protect the caliper guides-VAZ 2108. When assembling, all anthers, o-rings, cuffs are new.

What to look for when assembling

Before starting the installation of the piston, an o-ring is placed. The protective cover is installed in two stages: first, one edge is put on the piston groove, then, after its installation, the second edge is pulled over the brake cylinder. After that, the retaining ring is put on.

Guide pins must be lubricated. For these purposes, “Uniol-1” or an analogue is suitable.

After assembly, it is necessary not only to fill the brake fluid into the reservoir according to the level, but also to bleed the brakes.

Recommended:

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

DIY gas tank repair. How to repair a fuel tank

Often, motorists are faced with a malfunction of the fuel tank. In most cases, it starts to flow. To fix the problem with minimal losses, motorists have come up with different ways to self-repair

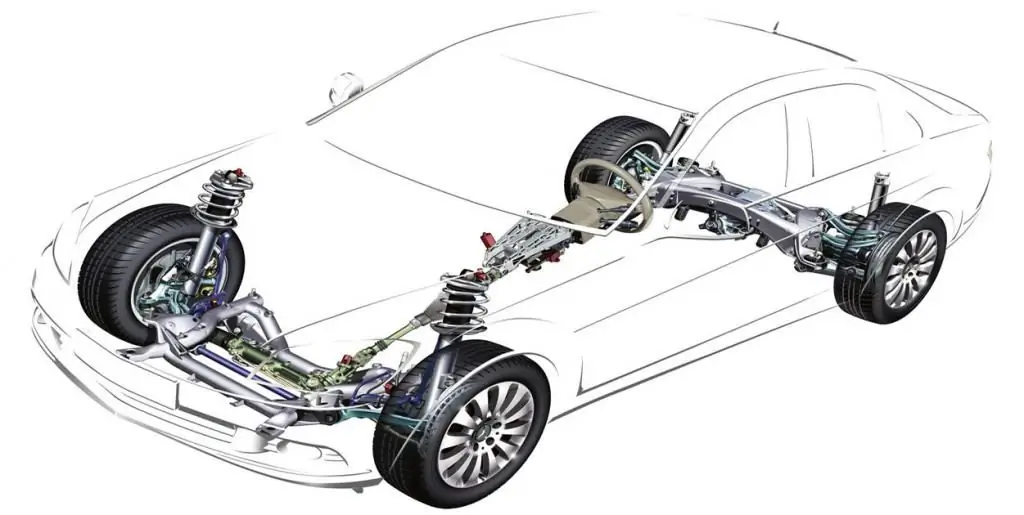

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

Wheel hub repair: signs of malfunction, causes, repair steps

Every motorist knows that the main rule on the road is safety, which he must ensure not only for himself and his passengers, but also for other road users. This applies not only to compliance with traffic rules, but also to the technical condition of the car

Self repair shock absorber. Do-it-yourself shock absorber strut repair

Shock absorbers dampen various kinds of vibrations, soften blows from holes, etc. For this, there is a special piston with liquid inside that goes up and down through a viscous substance