2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

Modern engine consists of many systems, including lubrication system, fuel system and ignition system. All of them change over time, undergo changes, become more perfect. But there are other details that have remained unchanged throughout its existence. For example, a crank mechanism. The fact is that since its invention, it has remained in its original form.

Its application is quite wide and it is not limited to internal combustion engines. It is used in such units where translational movement is required, since only it is able to provide not only the same period of such movements, but also a constant stroke, which is limited by the length of the crankshaft knee.

The crank mechanism was first used on a steam plant, after which, after the invention of the internal combustion engine, it migrated to the latest development. There are two types of such installations: one transmits the force from the crankshaft to the part that performs translational movement, the second receives this force from the piston, whichlocated on the other end of the connecting rod.

Consider the purpose of each part separately. The main part is the crankshaft. It can transmit force to the connecting rod or, conversely, receive it. It is made from high-strength steels, most often from cast iron. It also houses the flywheel, which serves to store the energy received. Many motorists install a lightweight flywheel on their engine, which makes the crank mechanism more mobile. It just picks up speed faster.

Now let's talk about the connecting rod. It is also made from hard steel, because the pressure on it can be enormous. In addition, its shaft is in the form of an I-channel, since its deformation is fraught with serious consequences that will damage the cylinder.

The crank mechanism has more torque than rotary engines because it uses the principle of leverage, that is, its force is proportional to the length of the knee. Hence the conclusion: the larger the knee, the higher the torque. The next part is the piston. The piston can drive the crankshaft, as in an internal combustion engine, or receive force from it, as in compressors. It is usually made of aluminum as it requires a soft metal so as not to damage the cylinder walls if touched. Along the perimeter of the circle there are grooves into which piston rings are inserted, they serve to seal and increase pressure.

In this case, the gasesdoing a great job.

The crank mechanism of an engine is calculated to average torque and RPM values, since a shift towards one indicator results in a loss in the other. The method of increasing the first is described above, but in this case the piston will have to travel a greater distance, which affects the "ceiling" of revolutions.

The assembly of the VAZ engine does not differ from that described above. It should be remembered that all parts of the crank must be thoroughly lubricated, as it rotates very quickly. From the very beginning of production, an oil film is created between the mating parts under pressure, which significantly reduces wear.

Recommended:

Engine gas distribution mechanism: device, principle of operation, purpose, maintenance and repair

Timing belt is one of the most critical and complex components in a car. The gas distribution mechanism controls the intake and exhaust valves of an internal combustion engine. On the intake stroke, the timing belt opens the intake valve, allowing air and gasoline to enter the combustion chamber. On the exhaust stroke, the exhaust valve opens and exhaust gases are removed. Let's take a closer look at the device, the principle of operation, typical breakdowns and much more

Purpose, device, timing operation. Internal combustion engine: gas distribution mechanism

The gas distribution mechanism of a car is one of the most complex mechanisms in engine design. What is the purpose of the timing, what is its design and principle of operation? How is the timing belt replaced and how often should it be done?

KAMAZ 5511 - a historical figure

KAMAZ 5511 is a whole era in the operation of construction dump trucks. Why is he remarkable? Reading in the article

The steering column is an important element of the driving mechanism

Many motorists believe that the steering column is not a very complex and important part of the car, and do not pay enough attention to this element of the control system. And in vain

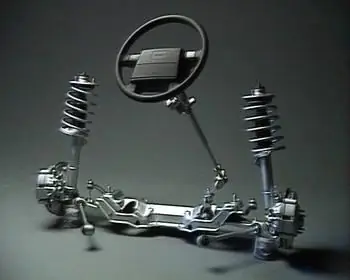

The device of the steering mechanism of the car

Many would agree that the engine is the backbone of the car. And indeed it is. However, it is also difficult to imagine a car without steering. This is an important and necessary element in every car. The task of steering is to ensure the movement of the vehicle in a given direction. This node consists of several components. These are the steering wheel, column, drive and steering gear. We'll talk about the latter today