2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:17

"Problem-free car" - this is how drivers briefly characterize the model, pleasing with excellent functionality. Can the machines on which the N52 engine is installed be attributed to this category, has it been thought out by engineers to the smallest detail? What is it good for, what difficulties do car owners have to face - further.

Series Features

The N52 generation of six-cylinder engines is classified as new. They are significantly upgraded in materials and layout compared to the previous generation of BMW powertrains. Not all drivers appreciated the advantage conceived by the developers due to different situations on the roads. The motor "debuted" in 2005. This literally “hot” unit, due to the presence of thermal testing and the compactness of its compartments, is the result of innovative technologies.

"Restyling" can be considered an easy-to-use vent valve, an oil pump endowed with variable performance and many other adjustments. The sensors of the lambda probe have acquired a broadband format, an airValvetronic supply.

Differences and similarities with the previous "brother"

Before the engineers introduced the N52 piston engine, cars of this brand traveled on M54 power units. How are they different?

- Valvetronic, an integrated gas distribution system on the N52 engine that can adjust valve clearances depending on the number of revolutions made.

- Dual Vanos system controlling exhaust and intake camshafts.

- It was decided to make the cylinder block from an aluminum alloy to reduce the weight of the power unit.

The similarity is as follows:

- throttle electronically controlled;

- DISA air intake system - separate.

Secrets of expressing design ideas

The crankcase of the BMW N52 engine is made of aluminum and magnesium alloy. The second component reduces the mass, but its participation leads to corrosion. It can't handle high temperatures. These negative conditions are offset by the use of aluminum inside the crankcase. Magnesium covers only the outer surface. Cylinder liners are also made of aluminium. To protect the bushings, the manufacturer introduced Alusil. Its task is to create a dense shell, protecting the cylinder walls from premature wear.

What about the hydraulic lifters?

In the operation of the engine from the BMW N52, motorists heard a sound reminiscent of the ticking of a clock. It occurred when starting a cold engine or at short distances. The problem was fixed in 2008. The sound now disappears immediately after the machine warms up thanks to the part upgrade.

If you buy a used car with an engine released earlier this year, you can pump the hydraulic lifters according to the "recipe" from the Bavarians themselves, who developed the "swallow". What matters:

- Warm up the vehicle.

- Turn on neutral.

- Keep the oil level at the specified rate.

2000 revolutions need to be achieved for two minutes. In the presence of a knock, we try to repeat the procedure after 15 seconds.

Problem areas with crankcase gases

According to reviews of the N52 engine, air enters into it during operation. The reason for this is the drying of the valve membrane, which leads to incorrect functioning of the main apparatus of the car. The owner hears "sneezing" and is not worried in vain. Simultaneously with the air, dirt and dust enter the “heart” of the machine. The intensity of wear increases, leading to the replacement of the entire assembly. It is important to get diagnosed on time. Similar actions apply to modifications of N52.

How do piston rings behave?

Over time, the owner notices the growing needs of the car for fuel. This is directly related to the obsolescence and occurrence of piston rings. They are on the N52 engines from BMW, reviews of which are often not in their favor, are installed too thin, with an uncomfortable shape. This applies to options with a volume of 2.5 liters: wearcomes very early. As a result, 1 liter is consumed per 1 thousand km. oils.

Difficulties with electronics

The electronic oil level sensor often drops out of operation or gives incorrect information. With a high fuel consumption, such behavior of the meter provokes oil "starvation", increased friction of the elements.

About motor requirements

When all the conditions for repair and maintenance are met, the device does not cause any particular problems. One of the negative points is the increased demands on the quality of the oil used in the tank. For the "power" of the unit, only premium category petroleum products are suitable, which the manufacturer advises to use. As a result, how should you care for the motor to extend its life?

Recommendations from experts

Note that each movement has its own lifespan:

- The working life of a regular lubricant is considered to be 150 thousand km. In connection with this fact, it becomes necessary to change the valve stem seals after 100 thousand km.

- Crankcase breather valve ready to last 3 years.

- Calculation of the pump resource was 120 thousand kilometers.

- It is important to change the fuel filter after driving 60,000 km. In the same period, it does not hurt to change the belts and rollers.

Car owners are advised to stick to somerules

Antifreeze is better to change 1 time in 2 years. The optimal mileage parameter is 60,000 km for this procedure. Replacing candles in this time period should not be neglected. The injectors should be flushed every 30,000 km. Overheating of the radiator is the worst "enemy" of the motor unit: it should not be allowed and it is better to wash it regularly. Cleansing costs about 4 thousand rubles, at an affordable price for the service, you can significantly add operational years.

Recommended:

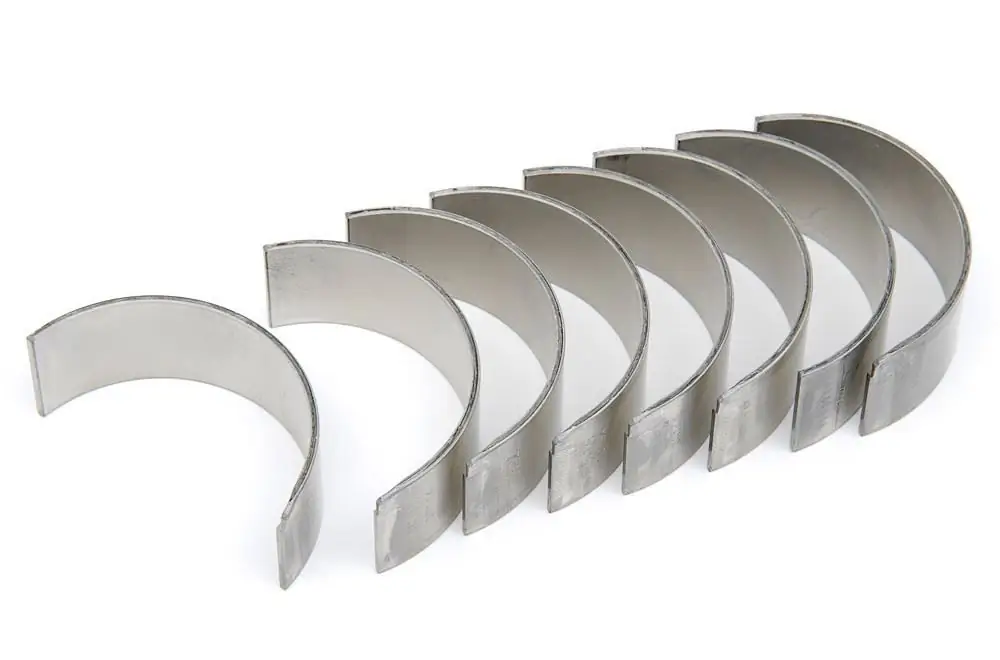

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

Yamaha XT 600: specifications, top speed, operation and maintenance features, repair tips and owner reviews

The XT600, developed in the 1980s, has long been considered a legendary model by the Japanese motorcycle manufacturer Yamaha. A highly specialized enduro over time has evolved into a versatile motorcycle designed to travel both on and off the road

"Yamaha Raptor 700": technical specifications, engine power, maximum speed, features of operation and care, reviews and owner reviews

Japanese company Yamaha, specializing in the development and production of motorcycles, is not limited to motorcycles and develops scooters, snowmobiles and ATVs. One of the best ATVs of the Japanese company is the all-terrain vehicle "Yamaha Raptor 700"

Repair and painting of a car body: features, technology and reviews

The body of a car is essentially its supporting structure. He is constantly under pressure. Moreover, these are not only mechanical factors in the form of shocks and vibrations. Every day, the coating of the body is exposed to the negative effects of external factors. Enamel is sandblasted, burns out. In addition, traces of rust appear at the site of deep scratches. Of course, all this significantly spoils the appearance of the car. But what to do?

"Yamaha Viking Professional": technical specifications, engine power, maximum speed, operation and maintenance features, reviews and owner reviews

"Yamaha Viking Professional" - a real heavy snowmobile, designed to conquer mountain slopes and snowdrifts. From the curves of the front bumper to the roomy rear luggage compartment, the Yamaha Viking Professional literally speaks of its utility snowmobile