2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

The engine is a complex multi-component mechanism, each detail of which ensures the correct and balanced operation of the entire system. At the same time, some play a big role, while others do not have such a value. The crankshaft, as well as all the elements related to it, is the most significant part of the engine. It provides the rotation of the wheels by transferring the energy of burning gasoline. Crankshaft liners are small semi-ring shaped parts made of medium hard metal and coated with a special anti-friction compound. In the process of long-term operation of the car, they are subject to severe wear, which makes it necessary to purchase and install new parts.

Description

The crankshaft bearings act as plain bearings to keep the crankshaft rotating. This process occurs as a result of the combustion of fuel in the cylinder chambers. Active friction of parts, caused by increased loads and high speeds, can bring the motor out ofbuilding. To prevent such a situation and reduce the degree of friction, all constituent elements with the highest value are covered with the thinnest micron oil layer. This function is assigned to the lubrication system of the motor, while the film on the existing parts is formed only under the condition of high oil pressure. The contact surfaces of the liners and the crankshaft journal are also covered with a layer of lubricant. Thus, the generated friction force is significantly reduced.

Types and sizes

VAZ crankshaft liners act as protective elements that prevent premature wear of mating parts. Depending on their location, they are divided into two varieties: indigenous and connecting rod. The latter, as mentioned earlier, are located on the necks of the shaft, the main ones are on the crankshaft at the place of its passage through the internal combustion engine and have a similar purpose. Different types of power devices require the use of appropriate elements, first of all, the internal diametrical size must be selected.

Repair parts both differ from each other and have significant differences compared to the new elements that new cars are equipped with at the factories. The parameters differ by at least a quarter of a millimeter, all subsequent options go through a similar step.

Destination

The crankshaft is constantly subjected to high physical and thermal loads during operation, the connecting rod bearings keep it on the axis, while functioningthe crank section is supported only by the elements indicated above. The mechanism of action of the necks is represented by internal clips, as a result, the crankshaft liners are external. Lubrication is supplied to them through a special oil pipeline network, in which the liquid moves under high pressure. This forms the thinnest film so necessary for the crankshaft.

Causes of failure

Structural damage and service wear are the most common reasons for replacement parts. Despite the regular supply of lubricant and careful operation of the motor, this process is inevitable. Over time, the surface of the necks becomes thinner, the free space between them becomes larger, because of this, the crankshaft acquires free play, the oil pressure decreases and, as a result, its supply. All this causes premature failure of the entire engine system.

Scrolling is the second reason for repairs. Many have heard about this or de alt with this problem on their own, but not all car owners know what causes this situation. Connecting rod liners have thin plates that lie in a special bed. At the same time, small protrusions are placed along the entire outer surface of the half-rings, they must be in contact with the front of the block, as is the case in new motors. Some conditions reduce the resistance of the antennae in relation to the liner, it sticks to the crankshaft journal and rotates. In such a situation, workengine stops. It is worth noting the most common causes of its development:

- the operation of the motor is associated with a constant excess of the established loads;

- grease is too runny;

- bearing caps with low preload;

- lack of oil, its excessive viscosity or the presence of abrasive compounds in the composition.

Preliminary work

If it becomes clear that it is impossible to do without repair of the power device, it is necessary to identify the degree of wear of all elements and determine the required dimensions of the crankshaft liners. Most motorists solve the problem of selecting dimensions by visual inspection; for greater accuracy, you can use a micrometer. It is also worth paying attention to the possibility of boring. If scrolling of elements is detected, they must be immediately replaced with new ones. Before starting the repair, this can be determined by the operation of the engine, in particular, it may often stall, or by the specific sounds of the crankshaft. When the necks are jammed, further movement becomes impossible.

Regardless of the situation, all parts of the mechanisms must be carefully examined. On the necks there may be damage of a wave-like appearance, which is easy to feel with your hands, in this case it is necessary to bore and install repair parts, the dimensions of which correspond to the installation site. Due to the large amount of damage, more intensive boring may be required, and as a result, parts will be required.size completely different from before. Therefore, the crankshaft connecting rod bearing is purchased after all procedures have been completed, so you can avoid having to return the item to the store.

Installation flowchart

The most common method of solving a problem among many people is to contact a car service. But replacing the crankshaft liners is within the power of any person who has even the slightest experience in repairing and has a certain set of tools. To simplify the task, you should follow a certain procedure.

First you need to check the gap between the bushing and the crankshaft. The check is made using a calibrated plastic wire, which can be found on the required neck. Then the cover is mounted together with the insert, they are tightened with a certain force corresponding to a value of 51 Nm. It is worth using a torque wrench for measurement. After removing the cover, the gap will be similar to the degree of compression of the wire. Using the nominal gap, it is necessary to evaluate the resulting parameter, the value of which is different for each individual brand. If it becomes clear that the gap exceeds the nominal value, that is, the degree of compression, then the installation of repair parts cannot be dispensed with.

Boring

All connecting rods are removed after successive clearance checks, the crankshaft is also dismantled and polished. Boring is possibleonly on special equipment - a centripetal, which is rarely found among ordinary car owners. Therefore, it will require an appeal to specialists. After grinding, the crankshaft liners of the appropriate size are selected. Here you can not do without such a tool as a micrometer, and trying on the selected elements. Further, all parts of the crankshaft are installed in the reverse order and the caps on the main bearings are screwed.

It is worth noting some features of the reverse mounting of connecting rods and liners. The latter are pre-lubricated with oil, the covers must also be screwed on. Compared to the preparatory work carried out, installation takes much less time. At the same time, do not forget about the operation of the crankshaft, which is characterized by high loads, as well as its high cost. Everything possible must be done to increase the period of operation. The main role here is played by grinding, carried out at the right time. This procedure ensures the smoothness of the necks and prepares them for further use.

What you need to know

Despite the complexity and complexity of such a part of the car as the engine, many people easily disassemble it for work. But when installing the liners, you should be especially careful, since excessive tension or, conversely, insufficient force can cause the elements to rotate again. If you are not confident in your abilities and knowledge, you should contact qualified specialists.

How to choose

Whateverreasons that caused the repair of the motor and the replacement of liners, crankshaft boring is a must. Installation of new parts is possible only on a polished or new mechanism. If there are damages and potholes on only one neck, all elements are processed to achieve a single overall size. Standard parts are installed during the assembly line of the engine. For example, crankshaft repair liners for VAZ cars are sold in four versions. That is, boring can be done a maximum of four times. Motors for such machines as Moskvich and GAZ have an additional fifth and sixth grinding up to 1.5 and 1.2 mm, respectively. The best option would be the selection of the required sizes by the person who was engaged in grinding. Boring can lead to the need to select elements whose size will significantly exceed the previous one. It depends on the depth of the ruts on the necks and their number. Inserts are available as kits for both types of necks.

Features of work

Replacing the crankshaft bearings requires the following rules:

- special dirt traps are located on the connecting rod journals, they must be cleaned during work;

- protrusions located at the joints and ensuring the fixation of the liners should freely enter the grooves (hand effort should be enough);

- replacement is done without adjusting actions;

- main parts work is carried out on a pre-removed motor, whileas when installing the connecting rod, it is not necessary to remove it;

- on completion of all actions, the engine must be run in.

Alternative crankshaft bearing replacement

Without removing the engine, you can also replace the crankshaft liners, the only thing is to take into account some difficulties. To ensure free access, the crankshaft must be at least 1 cm below the standard level. Here you can not do without removing the box or partially unscrewing it and moving it in the opposite direction from the motor. All belts must also be removed. To install the last liner, you often have to lower the shaft even lower.

Marking inserts

If it is necessary to select parts of standard parameters, it is worth starting from the color code that can be found on the elements to be replaced. If these designations are not on them due to significant wear, it is worth looking for markings on the connecting rods, more precisely on their lower heads. You also need to check the correspondence of the marks on the shaft itself, they determine the parameters of the necks to be installed.

Recommended:

KAMAZ 740 crankshaft: device and dimensions, repair, replacement

Crankshaft "KAMAZ 740": device, features, photos, operation, dimensions, maintenance. Crankshaft "KAMAZ 740": characteristics, repair, replacement, bearings. Comparative characteristics of the crankshaft "KAMAZ 740" and its analogues

Internal liners for different cars: replacement, repair, installation

Main bearings, represented by plain bearings, are of great importance for the operation of the engine: first of all, they provide ease of rotation of the crankshaft. At the same time, they are subjected to significant loads, which over time can lead to their displacement from the installation site

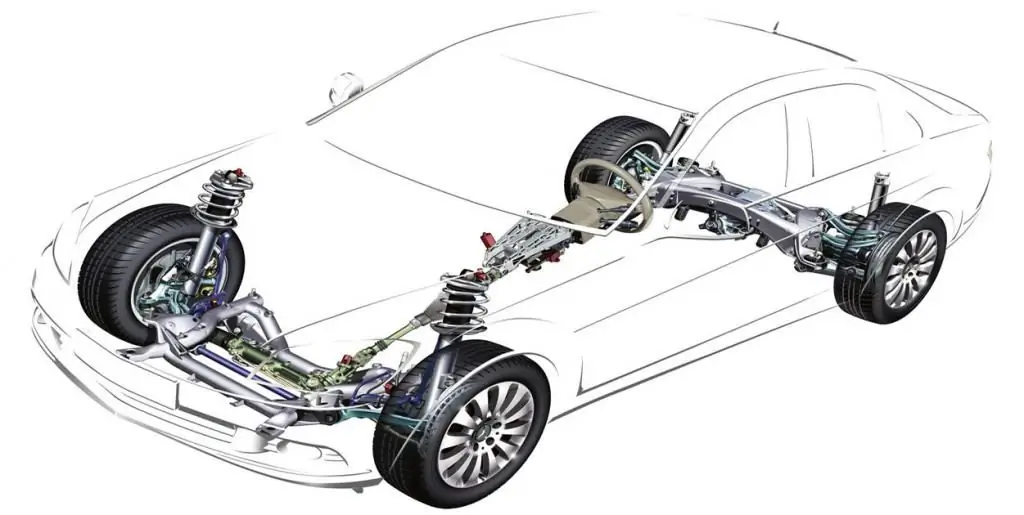

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

Windshield washer pump: device, principle of operation, inspection, repair and replacement

Mud on the roads is typical not only in autumn and spring, but also in winter and summer. Behind the cars, a long, impenetrable train stretches along the highway, instantly covering the windshield of the car behind with a film of dirt. The wipers and washer pump do their job, and you can go to overtake. But a sudden failure in the middle of the maneuver leads to the fact that two seconds later, nothing can be seen through the windshield. Slow down or keep going? What to do in this situation?

Documents for inspection: list. The procedure for passing the technical inspection

Citizens can conduct a technical inspection in any locality, regardless of the place of registration. In the event that until 2012 the state traffic inspectorate exercised control over the condition of the car, today dealerships or accredited maintenance operators are engaged in this. The centers conclude an agreement with the owners of cars, which does not act as a public offer