2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Crankshaft bearing rotation is one of the most common serious engine failures. This does not lead to its failure, but it affects performance. The following are the features and principles of the operation of the bearings, as well as the replacement of the main bearings.

Definition

Main bearings are elements of the engine, represented by plain bearings, which serve to limit axial movements of the crankshaft and ensure the rotation of the main journals in the cylinder block.

Operating principle

A lot of rotating elements are used in the design of cars. The ease of their rotation is ensured by the use of bearings. The most loaded rotating part of the engine is the crankshaft. Therefore, it is also installed on bearings, and plain bearings are most often used. Modern parts of this type are represented by steel sheets with an anti-friction coating. These are the main liners.

Typesearbuds

In addition to the main ones, there are connecting rod bearings. It is necessary to distinguish between them.

Except for the middle, the bearings have annular grooves. The details of the middle support are wider than the others. There are 10 such liners in total: 4 with a groove and 6 without. Main liners with grooves and one without are mounted in the cylinder block housing in third place. The rest are mounted in root caps.

Crank bearings are smaller in diameter. They are the same size, therefore interchangeable, and do not have annular grooves. A liner with a hole is mounted in the connecting rod, and without it in the cover.

Installation features

A set of root bearings is installed in a fixed position in special places called beds. The need for a fixed installation is due to two factors. First, some liners have oil holes, and these need to be aligned with similar channels in the beds. Secondly, this makes it possible to ensure the friction of parts on surfaces prepared for this.

Features of operation

During the operation of the engine, the liners are subjected to constant loads due to the mutual friction of these parts. Therefore, the installation of the main bearings must be carried out with a secure fixation in order to avoid their displacement by the rotating crankshaft. To do this, take action:

- First, they take into account the features of the friction of the parts under consideration, which manifests itself when they slide against each other under load. Its valueis determined by the coefficient of friction and the magnitude of the load on the interacting parts. Therefore, to ensure a reliable retention of the liners, the impact on them of the crankshaft should be reduced. To this end, the coefficient of friction is reduced by using anti-friction materials that are applied to the surface of the liners.

- Secondly, the main bearings are mechanically held in place. For this, two methods are used. These elements are installed with an interference fit, given constructively. In addition, each of them has an additional element, called a mustache, which also serves to hold.

Sizes

You need to know the overall parameters in order to correctly install the main bearings by providing an interference fit. The dimensions of these elements are selected based on the diameter of the bed. According to this parameter, the liners are divided into size groups, the designation of which is contained in the marking.

By size, the crankshaft main bearings are divided into nominal and repair. There are four repair sizes with a difference of 0.25 mm. They are used if the replacement is carried out for a ground crankshaft in accordance with its dimensions.

Reason for wear

As mentioned above, when the engine is running, each main bearing of the engine is constantly affected by a friction force that tends to move it from its original place. In the initial state in a serviceable engine, the strength of the parts is calculated with a margin in order to withstand such loads. For power units up to 200 hp. With.the stresses on the liner are from 0.1 to 1 kgf. The magnitude of its force is proportional to the load at a constant coefficient of friction.

In addition, the main liners are protected by the fact that they operate in the fluid friction mode. This is ensured by the use of oil, which creates a film between the shaft journal and the working surface of the liner. In this way, the parts under consideration are protected from direct contact, and a minimum friction force is achieved. The formation of an oil film is determined by the speed of mutual movement of rubbing parts. As it increases, the hydrodynamic regime of friction increases. This term is understood as an increase in the efficiency of pulling the film into the gap and an increase in its thickness as a result. However, as the speed of the parts increases, the amount of heat generated during friction also increases, and, consequently, the temperature of the oil increases. This leads to its liquefaction, as a result of which the film thickness decreases. Therefore, for an optimal mode of operation, it is necessary to achieve a balance between the considered processes.

If the integrity of the oil film is broken, the coefficient of friction increases. As a result, the torque generated by the crankshaft is increased even under constant load.

However, sometimes the reverse situation occurs, when increased loads for some reason lead to a decrease in the thickness of the oil film. Also, as a result of this, the temperature increases, especially in the friction zone. As a result, the lubricant thins out, further reducingthickness.

These processes can be interrelated and manifest together. That is, one of them may be a consequence of the other.

Consequently, the viscosity of the oil significantly affects the turning moment. The relationship between these factors is directly proportional, that is, the higher it is, the greater the friction force. In addition, with high viscosity, the oil wedge increases. However, with excessive viscosity, the oil does not enter the friction zone in sufficient volumes, as a result of which the thickness of the oil wedge decreases. As a result, the influence of oil viscosity on the rotation of the bearings cannot be unambiguously determined. Therefore, another property of this material is taken into account: lubricity, which is understood as the strength of its adhesion to the working surface.

The friction coefficient is determined by the roughness and accuracy of the geometry of the contacting surfaces, as well as the presence of foreign particles in the lubricant. In the case of the presence of particles in the lubricant or surface irregularities, the film is broken, as a result of which a semi-dry friction mode appears in some zones. Moreover, these factors are most intense at the beginning of the operation of the car, when the parts are running in, so the rubbing parts during this period are especially sensitive to overloads.

In addition, the main bearings of the crankshaft rotate due to insufficient force holding them in bed. It may be due to illiterate installation or be the result of wear as a result of exposure to torque.

Turn earbuds

Often there is a displacement of the main bearings from the installation sites by the crankshaft (rotation). This may be due to a decrease in the tension that holds the parts in question in the beds, under the influence of the factors mentioned above, and the antennae alone are not enough to hold.

Rolling of the main bearings from the bed can be identified by factors such as dull metallic knocks during engine operation and a drop in pressure in the lubrication system.

Repair

Replacement of main bearings requires wrench/screwdriver sets and a micrometer. Main bearing repair involves several operations.

- First of all, you need to provide access to the car from below. That is, you should install it above the viewing hole or on the flyover.

- The negative wire is removed from the terminal of the battery pack.

- Next, dismantle the engine oil pan (this is the easiest way to access, you can start disassembly from above and hang the engine).

- After that, the holder of the rear crankshaft oil seal is removed from the cylinder block.

- Then remove the camshaft drive cover with gasket.

- Then remove the chain from the crankshaft sprocket.

- Next, you need to mark the relative position of the bearing caps relative to the cylinder block and connecting rods relative to their caps.

- Then, with a 14 key, unscrew the nuts of the connecting rod cover and dismantle it with the liner.

- These operations are repeated for all connecting rods.

- When finished, slide the lids up.

- Then take out the main liners from the covers andconnecting rods.

- Next, with a key of 17, the bolts of the crankshaft main bearing caps are unscrewed.

- First, the cover of the last one is dismantled.

- It opens access to the thrust half rings in the grooves of the rear crankshaft support. They are removed by pressing on the ends with a thin screwdriver.

- These operations are repeated for the remaining bearing caps. In this case, you need to hold the crankshaft. It should be noted that the covers are marked with numbers, and the countdown is from the toe of the crankshaft.

- Then it is removed from the crankcase.

- First, the connecting rod bearings are removed, and then the crankshaft main bearings.

- The crankshaft needs to be inspected for damage. If they are present, the part is changed.

- Also examine the connecting rod and main caps by measuring with a micrometer. The obtained data are correlated with the tabular ones.

- If necessary, the parts are ground. In this case, you will need to measure them to calculate the repair size of the liners.

- The crankshaft is cleaned by washing with kerosene and blowing out the cavities.

- Then install new bearing shells.

- In the grooves of the bed of the fifth bearing, thrust half rings are mounted with grooves to the crankshaft.

- Next, check the gap between these parts. The normal value is considered to be 0.06-0.26 mm. If it is more than 0.35 mm, use rings of increased thickness.

- The crankshaft is installed in the block, pre-lubricated with oil.

- Then mount the bearing caps and check the freedom of rotation of the crankshaft.

- Connecting rods, liners and covers are installed on it.

- Thenmount the oil pan.

- After that, install the crankshaft holder with rear oil seal.

- Finally, the remaining parts are installed.

- Finally, adjust the tension of the timing chain, alternator belt and ignition timing.

Recommended:

Starter VAZ-2105: problems and solutions, replacement and repair rules, expert advice

VAZ-2105 is still popular with Russian drivers. It is distinguished by ease of operation and low cost of spare parts. However, if the car owner wants the car to work without problems, he must regularly check it for various faults

Crankshaft liners: purpose, types, features of inspection and replacement

The crankshaft is the most important part of the engine. It provides the rotation of the wheels by transferring the energy of burning gasoline. Crankshaft liners are small semi-ring shaped parts made of medium hard metal and coated with a special anti-friction compound

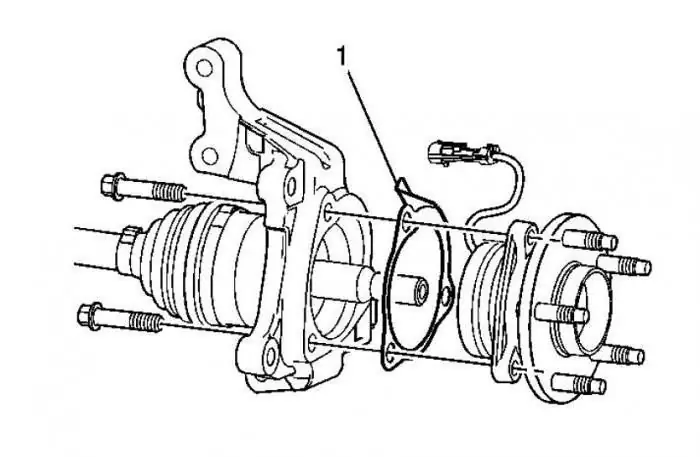

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Can I mix synthetics and synthetics from different manufacturers? Is it possible to mix synthetics with synthetics from different manufacturers?

Quality lubrication is the key to reliable and long engine operation. Often, car owners brag about how often they change the oil in their car. But today we will not talk about replacement, but about topping up. If in the first case there are no questions (leaked, filled and drove off), then in the second case, the opinions of motorists differ. Is it possible to mix synthetics and synthetics from different manufacturers? Some say it's possible. Others say it's strictly forbidden. So let's try to figure this out

Description of the engine on cars of different models

All moving technical devices, cars, construction equipment, water transport and more. etc., are equipped with power plants of various characteristics. In most cases, these are internal combustion engines, quite powerful and efficient, which have long established themselves as a reliable means of providing the motor functions of mechanisms