2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

The engine of most modern cars is located above the level of the gas tank, which excludes the flow of fuel "by gravity" and forces it to be pumped forcibly. Moreover, for the normal operation of the power unit, it is necessary to create a decent pressure in the system. For this, a fuel pump is installed on the car. Over the past few decades, it has not only changed structurally, but also changed its location. Therefore, it would be useful to recall where the gas pump is located, its device and the principle of operation.

Carburetor engine

First, a few words about the well-known mechanical fuel pump. It pumps fuel in cars with a carburetor. The key element is the diaphragm, which moves up and down to deliver fuel from the tank to the carburetor. The design provides for a valve system that ensures the pumping of gasoline and prevents its return to the fuel line.

Mechanical parts move directly from theengine, for this, where the fuel pump is located, its drive is provided in the cylinder block. Fuel injection can be carried out manually, using the provided lever. The pump does not require an independent lubrication system, as it is included in the line common with the engine.

Main malfunctions

The pump diaphragm is not only in constant motion, but also in constant contact with gasoline. This causes its deformation and leads to a loss of elasticity. Therefore, the main reason for the breakdown of the gasoline pump of a carburetor engine is the wear of the diaphragm. Most often, the membrane simply breaks. However, in most cases, this does not lead to high costs and long repairs. The diaphragm costs a penny when it comes to VAZ cars, and the pump itself is easily removed and repaired even by novice motorists.

Valves are another common cause of failure. If the fuel pump stopped pumping in hot weather, the reason is definitely in them. The fact is that the place where the fuel pump is located was not chosen very well on Togliatti cars. It heats up both from the cylinder block and from the radiator, which leads to a gap between the pump valves and the seats. As a result, fuel transfer stops.

In this case, experts do not recommend rebuilding the pump. Despite the fact that there are repair kits on sale, this will help for a while. Therefore, it is better to change the entire pump.

Injection engine fuel pump

Forcedinjection of fuel into the cylinders implies the presence of high pressure in the fuel system. The use of an additional pump for this would lead to a significant complication of the design of the car. Therefore, I had to completely change the existing one, while adhering to the following requirements:

- The pressure generated by the pump must be sufficient to operate the nozzles.

- The need to function in accordance with the commands of the electronic control unit.

- The pump must have a large capacity.

To meet all the requirements, the fuel pump had to be made electric. This solved some of the problems. For greater efficiency, the location had to be changed.

The injection engine fuel pump consists of the following elements:

- case;

- stator winding;

- rotor with impeller;

- check and pressure reducing valves;

- outlet fitting.

When describing the fuel pump, mention should be made of the coarse filter, the so-called grid, which protects its components from foreign particles.

Working principle

The electronic control unit supplies a voltage of 12 V to the fuel pump winding. The impeller begins to rotate with the engine rotor. In this case, gasoline is pressed against the walls of the housing and squeezed out of it into the fuel line. Then it enters the ramp and is distributed among the nozzles. At the same time, a vacuum is formed in the center of the rotating impeller, whichimmediately filled with new gasoline from the tank.

While the engine is rotating, the process is continuously repeated. At the same time, a working pressure of the order of 2.5 atm is established in the system. A pressure relief valve helps maintain it. It opens if the threshold value is exceeded. The check valve is designed to maintain pressure after the fuel pump is turned off. This is the working principle in a nutshell. Now about where the fuel pump of the injection engine is located.

Location

For a variety of reasons, it was impossible to place an electric fuel pump on the engine. In this case, first of all, it is impossible to provide sufficient performance, which means that one of the purposes of the gasoline pump will not be fulfilled - the creation of high pressure. In addition, the installation on the engine was needed to provide a mechanical drive, but when using an electric motor, this was no longer necessary. Therefore, the designers placed the fuel pump in the car's fuel tank.

Changing the location solved several problems at once:

- The pump turned out to be submersible. Thus, gasoline does not have to be pumped through the fuel line, which significantly increased the outlet pressure.

- The problem of cooling the electric motor has disappeared. The heat is removed by the fuel in which the windings of the fuel pump are located. The fact is that gasoline has a very low conductivity, this allows the electric motor to work when completely immersed in liquid. Any spark during operation of the pump is completely excluded, so that all fire safety rules are observed.

- Gasolinein addition to the main purpose and cooling, it acts as a kind of sound insulation. The electric motor immersed in it is almost inaudible in the car.

Cooling the pump with gasoline has one significant disadvantage. It is always necessary to have a reserve of fuel in the tank. If you run out of gas, which often happens to inexperienced motorists, the electric motor is likely to fail.

The fuel pump in the fuel tank is a design common to all injection engines. This remains the same for any manufacturer. At the same time, the place where the fuel pump is located, and how to get to it, depends on the make of the car. In most cases, access is as simple as removing the rear seats.

Connection diagram

Decent power of the electric motor does not allow the fuel pump to be powered from the electronic control unit (ECU). Therefore, the contacts of the intermediate relay are included in its circuit. Due to the high resistance, its winding can be connected directly to the control unit. Having worked with its contacts, the relay closes the power supply circuit of the electric motor.

The fuel pump connection wires pass through the entire interior of the car. Over time, their insulation can fray, which threatens with a short circuit. Therefore, the fuel pump circuit is protected by a fuse. To increase reliability, its face value is slightly overestimated. The block where the fuel pump fuse is located, on domestic cars, as a rule, is taken out separately from the general shield. This allows, in the event of a malfunction, to quicklyfind.

Character failures

The electric fuel pump is highly reliable and rarely fails. All failures, as a rule, are associated with the negligence of the owner in operation and maintenance. The most common faults are:

- Low rail pressure. The most common reason is the untimely replacement of the fine filter. Sometimes the mesh on the fuel pump itself gets clogged. In this case, you will have to remove it and clean it.

- The car does not start well after a long parking. The reason is a gradual drop in pressure in the system. The fuel pump check valve is to blame.

- Faulty fuse. In this case, when you turn the key, you can not hear the operation of the fuel pump and the click of its relay. The cause may also be damage to the computer. To find out for sure, you need to open the block where the fuse and the fuel pump relay are located. To check, you need a test lamp, a probe or a tester. It is necessary to check the voltage on both sides of the fuse. The ignition must be on. If there is no voltage anywhere, then the computer or the wiring from it to the fuse is faulty. Further diagnostics in this case is best left to specialists. When the test lamp lights up on one of the contacts, you need to change the fuse.

- Relay failure.

- Failure of the fuel pump due to lack of gasoline in the tank.

Fuel quality

Except non-complianceservice intervals Another common cause that leads to a malfunction of the fuel pump is gasoline. Not all gas stations have the same quality. Some of them violate the rules of transportation and storage. As a result of systematic refueling at such gas stations, a large number of foreign particles accumulate in the tank, which clog the fuel pump grid.

This is manifested by a loss of engine power, car jerks when driving and, oddly enough, excessive fuel consumption. You have to remove the fuel pump and carry out its maintenance. If this is not done, then it will become impossible to drive a car, the fuel will simply stop flowing to the injectors. The reason for this is clearly visible in the photo of the fuel pump with a clogged mesh.

Conclusion

The electric fuel pump is very reliable and maintenance free. For its reliable operation, it is important to change the fine filter in a timely manner and refuel only at proven gas stations. In addition, a small reserve of gasoline must remain in the tank. A dry tank is the most common reason for buying a new fuel pump.

Recommended:

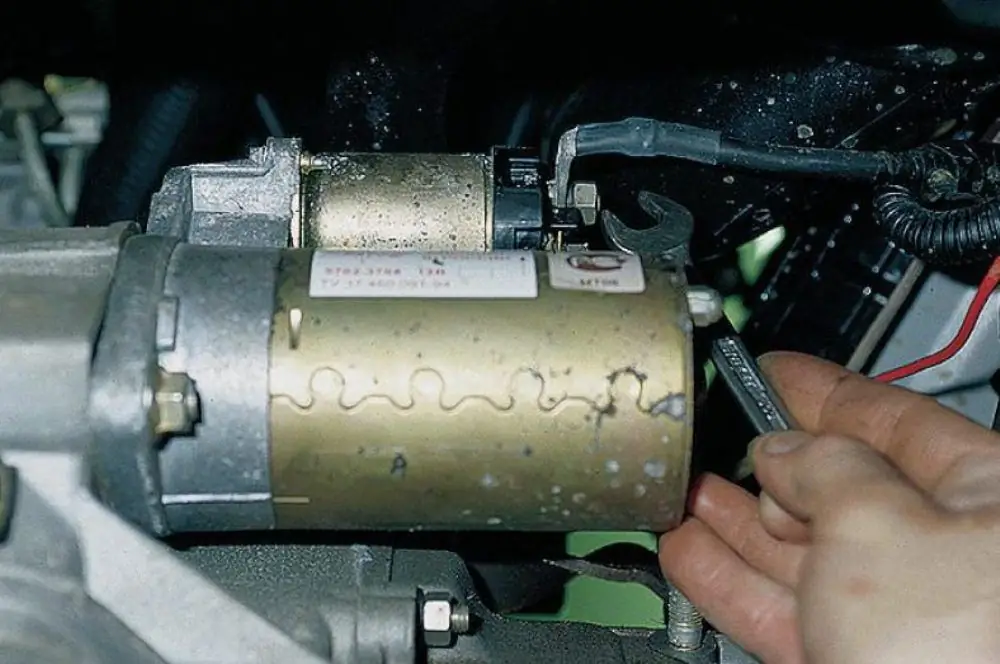

Where is the VAZ-2112 starter relay located? Location, purpose, replacement and device

The starter relay on the VAZ-2112 performs an important function on any car, regardless of model. Failure of this device leads to the fact that the car will not start. Drivers who are engaged in self-repair of the vehicle need to know where this unit is located and how to fix it if any malfunction occurs

Gasoline pump does not work: possible causes and solutions

The fuel pump is not working - a breakdown that cannot be called rare. But why does this mechanism fail? What are the causes of malfunctions? How to increase the resource of the fuel pump? You will find answers to these questions in the article

How does an automobile membrane tank (expansion tank) work and what functions does it perform?

Oddly enough, on the Internet you can find thousands of articles about thermostats and radiators, but few people remember such an important detail in the cooling system as a membrane expansion tank. It has a visually simple design and primitive functions, but its presence is very significant for every car. Often, motorists have come across cases when the internal combustion engine temperature sensor gives exorbitant values. But few thought about the reasons

Gasoline pump does not pump gasoline. Possible causes, ways to solve the problem

The article shows the possible reasons why the fuel pump does not pump fuel. Methods for troubleshooting the fuel pump of carburetor and injection engines are also described

Ford Focus-2 trunk does not open. How to independently open the fifth door and make repairs. How much does it cost to work in a service center

"Ford Focus-2" has received wide popularity not only in the Russian market, but also in European countries, in the US, China and India. Motorists are happy to buy sedans, hatchbacks, station wagons from Ford because of their reliability, ease of repair and comfortable suspension. However, with a mileage of more than 100,000 kilometers, the following malfunction often occurs: the trunk of the Ford Focus-2 does not open. The problem manifests itself unexpectedly and is noticed both on restyled and pre-styling models