2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

During engine operation, not only exhaust gases are released. Few people know about crankcases. Vapors of fuel, oil and water accumulate in the lower part of the engine. Their accumulation worsens and destabilizes the operation of the motor. To remove these substances, a crankcase ventilation valve is provided in the design of the car. Tuareg is also equipped with them. What is this element and how is it arranged? You will read the answers to these and many other questions in our today's article.

Characteristic

Note that the crankcase ventilation system has been used for a very long time. The essence of its work is very simple - the inside of the engine is connected to the exhaust manifold with a hose. Under the action of the vacuum force, water and oil vapors accumulated in the engine are taken back into the intake tract.

On BMW carscrankcase ventilation valve is designed in such a way that the gases move in only one direction.

Types

There are two types of these systems:

- Open.

- Closed.

The first type was used on older motors. Here, ventilation was carried out in the cover of the pushers through the outlet tube. All gases went outside, into the engine compartment. The system was inefficient, so in the late 70s, car manufacturers began to use a closed crankcase ventilation valve. Opel is no exception. The advantages of such a system were as follows:

- The level of emissions of substances into the atmosphere decreased.

- The engine did not experience "starvation" and worked stably at any speed, giving the right thrust.

- The pressure inside the crankcase was decreasing. This contributed to a greater resource of oil seals and gaskets (in an open system they were simply squeezed out).

Valves are also distinguished by the type of exhaust gases into the intake manifold. There is a direct-flow crankcase ventilation valve and a forced type. On Volga vehicles with ZMZ-402 engines, gasoline and oil vapors were removed through a thick pipe. He connected the valve cover to the carburetor. As a result, the gases entered directly into the intake manifold, without affecting the mixing of the portion of the fuel-air mixture.

Device

Currently, cars use a membrane-type crankcase ventilation system valve. It consists of the following elements:

- Lids.

- Diaphragms.

- Return spring.

- Cases.

The latter has 2 fittings. One is designed to supply crankcase gases, the second - to remove them.

How does it work?

The action of the mechanism depends on the mode of operation of the engine. So, on a muffled motor, the valve is closed by a membrane under the force of a return spring.

When the unit is idling, the membrane overcomes the force of the spring (since a vacuum is formed in the system), and part of the gases enter the intake manifold. Then they, together with the fuel-air mixture, are burned in the chamber and released into the atmosphere. At speeds above one and a half thousand, the channel is completely freed by the diaphragm. So, crankcase gases enter the intake in full. Thanks to the membrane, they will not be able to get back into the crankcase.

How to check

As the operation progresses, the crankcase ventilation valve begins to clog. However, this does not mean that the element has stopped working and needs to be replaced. To check if the crankcase ventilation valve is working, its pipe is disconnected from the engine and blown in one direction. On a working mechanism, air in the opposite direction should enter in a small volume.

There is another way to check the crankcase ventilation valve. To do this, start the engine and disconnect the pipe from the intake side, after loosening the clamp on it. Next, put your thumb on the fitting. With a good valve, it should stick. itindicates that there is a vacuum in the system.

Some diagnose the very condition of the engine using this valve. So, a transparent fuel filter cuts between the hose and the intake manifold (this is installed on carburetor engines). After some time, oil and soot will appear on it. If the filter becomes dirty in the first 100-150 kilometers, then the cylinder-piston group in the engine is faulty. Although the system is designed to circulate harmful substances, the valve should not have so much dirt in such a short period of time.

Possible malfunctions

If there is no vacuum in the system and gases do not enter the intake manifold, the reason is one of two:

- Failed crankcase ventilation valve.

- Clogged system hoses.

In the latter case, the main cause of the problem is the wear of the piston group. It is worth checking the compression in the cylinders. Also check the oil scraper rings. If they are weakened or “laid down”, oil will enter the system in large quantities. The hoses will clog. At the same time, the valve membrane itself is broken. Why is this phenomenon dangerous? If the system cannot pump gases normally, they will accumulate in other places, and under high pressure. So, they squeeze out seals and gaskets. The engine loses thrust, it is unstable at idle.

If the compression is correct, andthe hoses are not clogged, the valve itself is to blame. In such a situation, it is enough to simply replace it with a new one.

Price

How much does a crankcase ventilation valve cost? "BMW" is equipped with a device for 2-2, 5 thousand rubles. For a Ford Focus car, this element costs up to one and a half thousand rubles. For domestic VAZs, the valve costs no more than a thousand.

How to replace with your own hands?

Let's look at how to change this element yourself, using the BMW M-54 engine as an example. So, first you need to find the crankcase ventilation valve itself. It is located at the front of the engine, under the intake manifold. Having reached it, we remove the idle speed controller and the electronic throttle. For convenience, you can dismantle the intake manifold itself (but not necessary).

Now we disconnect the hoses from the ventilation valve and take the element itself out. Installing a new device is done in reverse order. For reliability, all hoses are secured with clamps.

Conclusion

So, we found out how the crankcase ventilation valve works and works. When operating the car, you should periodically check the condition of this unit. After all, if the valve is clogged, you can "get" to replace the seals and gaskets. And this is an additional cost of both money and time. We also note that if there is a blockage in the hoses, the matter will not be limited to one cleaning. If there are problems with the piston, this soot is formed in a couple of days. Ride withsuch a fault is not recommended. After all, the pressure in the crankcase is many times higher than the norm. It is necessary to check the engine compression and, if possible, the condition of the oil scraper rings.

Recommended:

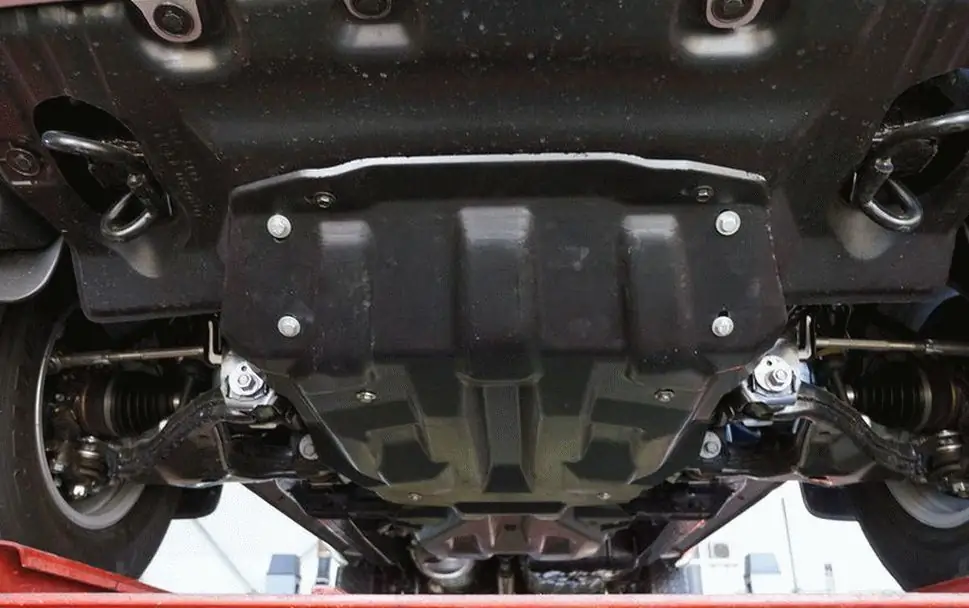

Composite crankcase protection: characteristics, principle of operation, pros and cons

The need to install crankcase protection has not been disputed by car owners for a long time. The bottom of the car covers various important units, including the transmission, transfer case, engine crankcase, chassis components and parts, and much more. Hitting any obstacles can damage them. To avoid this, crankcase protection is installed - metal or composite

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

Crankcase ventilation system: device, types, principle of operation

At present, despite the rapid development of technology, it is not possible to create a completely sealed pair of friction parts - a cylinder and a piston ring. Therefore, combustion products accumulate in the internal combustion engine over time during operation

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

Solenoid valve - device and principle of operation

The solenoid valve is an electromechanical device that is controlled by electric current. The latter passes through an electromagnet (a coil wound around the core), as a result of which a magnetic field is formed. By its action, it can open and - vice versa - close the solenoid valve