2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:12

Every car owner knows that special sensors control the operation of systems. They are located in different places of the mechanisms. If such elements fail, the likelihood of failures in the operation of system elements increases. In this case, the repair will be costly. To eliminate the possibility of such a nuisance, a periodic check of the system sensors is carried out.

Control devices are responsible for the operation of many nodes and mechanisms. They need to be properly controlled. How to check the temperature, pressure, air and other varieties will be discussed in detail in the article.

Sensor operation

Before you get acquainted with the technology of how to check the idle speed sensor, oil pressure, temperature and other types of control devices, you need to consider the features of their work.

The main instruments of the presented type monitor the functioning of the motor and related systems. It is the engine that needs precise control of the operation of its elements and systems. Its failure leads tonecessitates a major overhaul. To avoid large financial costs, it is recommended to check the performance of the sensors.

Control devices are responsible for testing the level of heating of the system, coolant. They measure the status of various components during idling, in normal mode, etc. Every car owner should know how to check the temperature, air, oil pressure and other similar devices.

Temperature sensor

There are a number of recommendations on how to check sensors on VAZ, Chevrolet, Mercedes and other car brands. One of the most important signaling devices is a device that measures the heating of the coolant. This device transmits the collected data on the state of antifreeze to the motor control unit. He, in turn, on the basis of the data received, adjusts his work. In this case, the correct fuel level and ignition angle are set.

On many cars (including VAZ, Kalina, Priora, Granda, etc.), the temperature control sensor switches the system to an electro-ventilation type of cooling. His readings are often displayed on the dashboard. This allows the driver to monitor the condition of the engine and its antifreeze. In modern vehicle models, temperature control sensors are installed that have a negative heating coefficient. This means that as the heat increases, the resistance of this element decreases.

Principletemperature sensor operation

When considering how to test engine sensors, you need to learn the basic principle of their operation. One of the most important in the system is the antifreeze temperature control device. The control unit sends an electrical signal to this sensor. It has a voltage of 9 V. When this happens, the reader takes a reading of the resistance readings at the sensor contacts. The system sends this data back to the control unit. In doing so, she will be able to calculate, from a given logarithm, how the engine should work in such circumstances.

If the temperature rises, the resistance should decrease. In this case, the system, using its special mechanisms and electronic devices, adjusts the level of fuel consumed during engine operation. This allows you to lower the heating temperature at the right time. Antifreeze in this case will be able to properly cool the system. With a strong drop in temperature, the presented mechanism will help adjust the engine in the opposite direction.

How to remove the sensor?

Considering how to check the coolant sensor, you need to learn how to properly dismantle this element of the system. Drivers often confuse this element with a device that controls the activation of a fan. It does not need to be looked for on the back of the fan. The temperature sensor is almost always installed in one of two possible areas. In the first case, an antifreeze heating control device can be installed nearthermostat. Moreover, it can be located directly in its body. In the second case, the sensor is installed in the cylinder head. It should be in close proximity to one of the pipes of the cooling system.

To dismantle, you will need to drain the antifreeze from the radiator. Next, remove the air filter if the car is of the injection type. You can unscrew the sensor with a wrench. In foreign cars, dismantling can be more difficult. Often the sensor is located at the rear of the cylinder head. In this case, when dismantling, you will have to disconnect several hoses.

Check sensor operation

The method of how to check the temperature sensor is described in detail by the vehicle manufacturer. To carry out such work, you will need tools, a tester, a container of water, a stove, a thermometer with divisions up to 120 ºС, as well as a basin for antifreeze. First you need to turn off the radiator, drain the antifreeze from it. After that, the sensor is dismantled. A container of water must be placed on a gas or electric stove. The sensor must be lowered into the liquid. Its brass part must be completely immersed in water. The plastic should be on top.

You need to connect a tester to the connectors of the device. It is included in the resistance measurement mode. Next, you need to heat the water and record the readings of the multimeter. It is necessary to study the manufacturer's instructions, which indicate the operating parameters of the sensor. Most often at a temperature of 100 ºСresistance is 150-200 ohms. When the temperature drops to 20 ºС, this indicator should increase to 3-4 kOhm. This indicates that the sensor is OK. Otherwise, it will need to be replaced.

Idling sensor

Drivers may be interested in how to check the vehicle's idle speed sensor. This device is also responsible for ensuring the stable operation of the engine. He only controls this process at idle. This sensor controls the amount of air that is supplied to the motor in this mode of operation.

In this case, it is no longer the antifreeze liquid that is measured. The idle air supply system has certain components. It has a valve in the form of a conical needle. This element prevents air from entering the system. The needle is driven by a small motor that runs on electricity. The damper is set in motion when the motor is turned on. The needle can open or close the gap through which air enters the engine. Moreover, the diameter of this hole is also adjustable due to the special configuration of the damper.

Signs of malfunction

Before you learn how to check the air sensor, you should consider under what circumstances you need to suspect a malfunction of this particular element of the system. If the control device fails, the car will stall when stopped at a traffic light. In this case, the driver will have to hold the gas pedal while waiting for the green light.

On a malfunctionidle speed sensors also indicate unstable engine speed. It can be heard even without the use of special equipment. Also, the engine takes a long time to warm up. Even in warm weather, starting the car becomes problematic. Even after warming up, for a long time you have to go on a “suction”. Also, the driver may notice that when the transmission lever is moved to the neutral position, the engine starts to work unstably. At the same time, he can even stall. In this case, it will be necessary to check the idle speed sensor.

Check idle speed sensor

If the listed failures appear, you need to consider how to check the idle speed sensor. It is located on the throttle. Her rope is attached next to him. Above the idle speed sensor is a throttle position control device. It is necessary to turn off the ignition and dismantle the presented device. The sensor can be attached with adhesive or bolts. In the first case, you will need to dismantle the entire throttle assembly. The bolted connection will only allow the sensor to be disconnected.

Next, you need to connect the wires of the on-board network to the sensor. You need to put your finger on the conical needle. Next, the ignition is turned on. If after that small pushes of the needle are felt, then the sensor is working. Otherwise, this structural element will be motionless. The sensor will need to be replaced.

Check oil pressure sensor

Faulty oil pressure sensor can lead to engine malfunction. Therefore it needsperiodically check for functionality. How to check the oil pressure sensor? There is a certain technology for this. It involves the dismantling of the control device. Next, you need to connect the contacts of the multimeter to the sensor. It shows zero resistance. Next, with the help of a pump, you need to pump the oil. The chain must break. The device in this case shows infinity. This indicates the full he alth of the sensor. By knowing how to check the sensors, you can ensure the normal operation of the motor and all systems for a long time.

Recommended:

Assembling the box "Izh-Planet 5": detailed instructions, diagram and recommendations

Assembling the box "Izh-Planet 5": step by step instructions, features, tips, diagram. Disassembly and assembly of the box "Izh-Planet 5": recommendations, photos

Temperature sensor in the VAZ-2115: principle of operation, design and verification

Compliance with the thermal regime of the engine is one of the most important conditions for its long-term operation. To control the temperature on the VAZ-2115, like on any other car, there is a pointer and a corresponding sensor. The failure of one of them can ultimately lead to overheating of the power unit. Considering the importance of the temperature sensor in the VAZ-2115 for the trouble-free operation of the engine, knowledge of its structure, location and verification procedure will not be superfluous

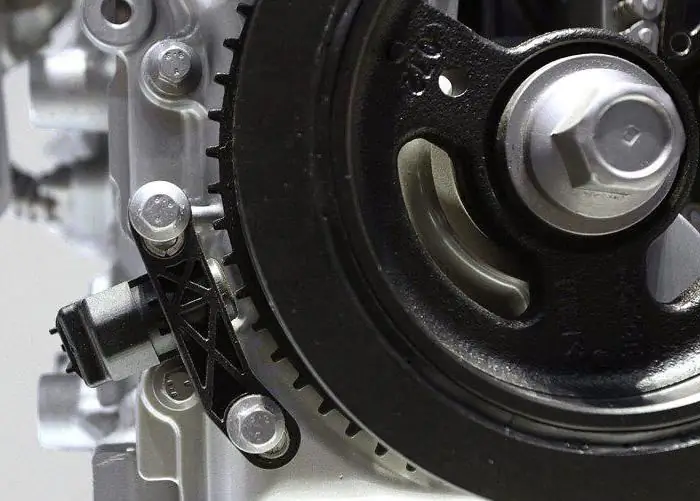

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

Replacing the cylinder block: instructions and recommendations

Probably, any motorist would like to learn how to repair his car on his own. Doing repairs with your own hands, you can not only gain the necessary experience, but also save a lot. Let's learn and find out how to replace the cylinder block on gasoline engines. This type of repair seems complicated, but there is nothing supernatural here

Pasting the headlights with a film with your own hands: instructions and recommendations

Before starting work on pasting the headlights with anti-gravel film, it is necessary to decide how exactly the process will take place. For example, whether the entire surface of the optics will be pasted over or only “cilia” on the headlights will be processed. You can also choose several color options for the film and create an applique combination