2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

All vehicle systems must be in good working order during its operation. But special attention must be paid to the brakes. Indeed, often the life of the driver, passengers, other road users and pedestrians depends on the state of the brake system of the car. It needs to be serviced periodically. This consists in replacing brake pads, discs, fluid, as well as calipers. For example, lubrication for brake cylinders during their maintenance and replacement is simply necessary. We'll talk about all this.

Lubricating the caliper guides

Before you go directly to the cylinder, you need to deal with its guides. The brake system generates a lot of heat during operation. This leads to the fact that often the connections stick tightly. This also applies to guides that begin to wedge. There's nothing in itgood, because it can lead to serious consequences. Wedging helps to ensure that the pads are constantly pressed against the disc. This leads to significant overheating of the system. As a result, the pads burn, the discs become crooked. Yes, and the tire in such conditions can easily catch fire. That is why when servicing the caliper, it is necessary to treat the guides with a special lubricant. Which one, we will understand in this article.

Properties of lubricant for cylinders and guides

Since the node is heavy-loaded and heats up to 300 degrees Celsius during operation, and even higher with aggressive driving, the approach should be appropriate. Brake cylinder grease should have the following specifications:

- working temperature - from 150 degrees Celsius and above;

- resistance to aggressive environments (s alt, reagents);

- minimum change in viscosity with increasing temperature.

It is on the basis of the above parameters that lubricant for brake cylinders and guides should be selected. Fortunately, at the present time, the assortment is simply huge, so there should not be a choice of labor.

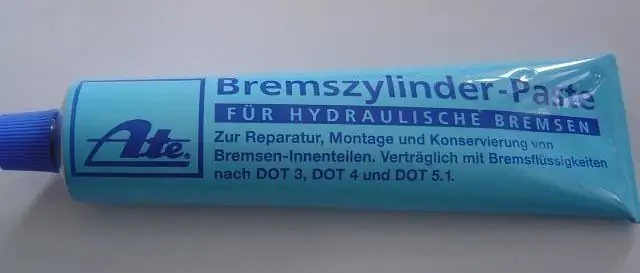

Copper grease for brake cylinders and calipers

It is the most common and popular among motorists. It is not afraid of high temperatures and is inexpensive, which makes it so popular. Most often used for processing discs, brake pads, as well as for calipers and other brake elements.systems. It is worth noting that copper grease is applied to the back of the product. If these are pads, then their front side should not be covered with any lubricant, this also applies to discs.

The process of applying the paste is also extremely simple. To do this, the treated surface is cleaned of dirt and corrosion. Further, with the help of a brush, lubricant is applied and evenly distributed over the entire surface. It is worth noting that it is also sold in cans, in which case it must be sprayed after reading the instructions for use.

High Temperature Grease Base Base

On the shelves of car dealerships is currently just a huge selection. But if you look, then there are only 3 large groups:

- mineral based;

- synthetic base;

- mineral or synthetic base with low metal content.

If you figure out what kind of grease should be used for the brake cylinder boot, then the one that is made on a synthetic basis is best suited. This is due to the fact that it is neutral to rubber and plastic products. Therefore, the anther does not corrode and is ideal for processing the brake piston or caliper guides. The used base provides a number of advantages, such as low volatility, high temperature threshold, insolubility in water and other liquids. In general, an excellent choice, though not always budget.

Where cheaper is grease for brake pistons onmineral base. But still, it is better suited for guides, as it can withstand temperatures from -45 to +180 degrees Celsius.

Ceramic Grease

A relatively new development that has already gained popularity. It is not cheap, but the claimed benefits are very encouraging. An increase in the performance of the lubricant is achieved due to the presence of a fine fraction in the composition of ceramics. At the moment, this is one of the best methods for protecting brake cylinders and their seat from corrosion. In addition, the processed nodes exclude the possibility of sudden temperature changes, the formation of dirt and dust on the surface.

Despite the high cost of such products, they are extremely popular among motorists. Can be used as a lubricant for rear brake cylinders, which are less stressed than front ones. Among the most popular manufacturers, Liquid Moli can boast of high quality. Well, now let's move on and consider a few more extremely important points.

How is the brake system serviced?

Complex lubrication is often recommended when replacing brake pads or discs. There is nothing complicated here. First of all, we inspect the condition of the guides. We clean the fingers and seats from rust and treat with a certain amount of lubricant. Copper, graphite, etc. will do. As for the piston, then lubrication is needed to reduce friction and protect againstcorrosion. It is desirable to treat the surface of the part with a small amount of ceramic grease. It will effectively protect the surface from rust.

The extremely important detail is that it is worth checking the condition of the anther regularly. If it is torn, then no amount of lubrication will help. First you need to replace the rubber seal and then lay the lubricant. In addition, it should not be too much, as it will begin to squeeze out through the anthers and cuffs, which is not good.

Pro Tips

Many experts recommend not skimping on caliper lubricants and buying only proven products. For example, the optimal grease for brake pistons based on silicone. It is completely safe for anthers and at the same time is high-temperature. Therefore, it works effectively both in winter and summer.

Car service specialists often do not fulfill their direct duties. For example, when replacing pads, calipers and guides should be cleaned, but no one does this. Therefore, it is better to do it yourself, especially since there is nothing complicated in this and even a beginner can handle it. Do not neglect the maintenance of the brake system, but it also does not make sense to look there every 500 kilometers. Inspect everything while changing brake pads.

Which lube is best?

It is advisable to use different types of lubricant depending on the workpiece. For example, excellent for caliper guidessuitable graphite lubricant. It is inexpensive and can withstand high temperatures. Protects metal products from corrosion and prevents sticking. One of the most affordable options is TRW products.

Optimal grease for brake cylinder pistons should be silicone or ceramic based. The best manufacturer in this regard is Febi. Cheap and cheerful. But the anti-creak Liqui Moly is not recommended for laying under the piston boot, as it can cause destruction of the rubber seal.

Anti-squeak paste is great for refinishing the brake shoe plate and retaining caliper. This is usually where its use ends. Remember that the lubrication of the brake cylinder cuffs should not be carried out with pastes that corrode the rubber seals. This can lead to complete destruction of the piston and caliper.

Summarize

As you can see, there is nothing complicated in car brake maintenance. But at the same time, it is extremely important to regularly lubricate all elements of the caliper, which work at high temperatures every time. Pay attention to the anthers of the guide pins. They are also subject to wear, resulting in a rather unpleasant knock on bumps. This happens due to the fact that the finger dangles freely in the seat and is not held by the plastic sleeve.

As far as lubricants are concerned, there are just a huge number of them at the moment. Any paste for lubricating brake cylinders, if it is intended for this purpose,suitable for use. It is not recommended to lubricate the parts of the brake system with simple engine oil or grease, etc. All this will not lead to anything good.

Many parts of the brake system, with proper maintenance, can serve for 200-300 thousand kilometers or more, this applies to calipers, guides, pistons, etc. Pads and discs are more of a consumable, but it is also desirable to look after them. All this will allow you to feel more confident behind the wheel and know for sure that the brakes will not fail, because everything is lubricated and checked there. Often there is a problem with the jamming of the guides and the tight running of the brake cylinder, which occurs in 90% of cases due to insufficient lubrication. If every time you change the pads, brake cylinder anther grease is used, then you will not know the problems with the car's brake system.

Recommended:

The best batteries for a car: review, reviews. The best battery charger

When car enthusiasts think about choosing a battery for their car, the first thing they look at is tests conducted by independent experts and various specialized agencies. However, the results show that even with the same parameters declared by manufacturers, products of different brands can have the same different characteristics. Everyone wants to buy the best battery and therefore you need to know how to choose it

Brake stand for cars. Stand brake system

How to check the brakes of a car? In order to analyze the state of the brake system, 2 methods are used - road and bench. In our article we will talk about the bench method

Where and how to pierce brake discs? Grooving of brake discs without removal

The brake system of a car requires regular maintenance. In particular, this applies to replacing brake pads, inspecting discs for defects, changing fluid, etc. But far from always this is done on time and is done at all. Many turn to the service station only in case of obvious malfunctions. But all this can be avoided if you change the pads in a timely manner and do not forget to grind the brake discs

The order of operation of the engine cylinders

The order of operation of the cylinders depends on their location and the mutual location of the crankshaft cranks. It is provided by the action of the gas distribution mechanism and the supply of fuel (in a carburetor engine - by the ignition system), ignition of the working mixture and timely closing and opening of valves

Minimum brake pad thickness. How to determine brake pad wear

The brake system is responsible for the safe braking of the car. The efficiency of the process depends on its serviceability. The number of mechanisms in the brakes is quite large, and all of them should work like clockwork, because the failure of one will entail at least unpleasant consequences. Let's talk about what should be the minimum thickness of the brake pads, as well as how to check for wear