2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:13

The order of operation of the cylinders depends on their location and the mutual location of the cranks in the crankshaft. It is provided by the action of the gas distribution mechanism and the supply of fuel (in a carburetor engine - by the ignition system), ignition of the working mixture and timely closing and opening of valves.

Cylinder order of four-cylinder engines

At the crankshaft, all the cranks are in the same plane, while two of them are turned in one direction, and the others - in the opposite direction, that is, the angle between adjacent cranks is 180 degrees. The pistons of the second and third cylinders in this arrangement go up, at the same moment the pistons of the fourth and first go down. Naturally, it is impractical to start the working stroke simultaneously in two cylinders. Therefore, if it starts in the first, then the intake should begin in the fourth. At this time, the second cylinder may be exhausted or compressed. In any location of the crankshaft in one of the cylinders, a workingmove. In each subsequent one, it starts after the previous one exactly 180 degrees later.

Cylinder order in a six-cylinder engine

In it, the crankshaft cranks are arranged in pairs, one to one at an angle of 120 degrees. Each subsequent pair of pistons after the previous one comes to a dead center again after 120 degrees. Cylinder flashes occur at the same intervals. This order of operation of the VAZ cylinders has the advantage that flashes in two neighboring ones do not occur in a row. With this alternation, the best conditions for the operation of the connecting rod and crank mechanism are achieved.

V-engine cylinder order

Cranks in the shaft can be located at an angle of 180 and 90 degrees. Each crank is connected to two connecting rods. One of them is connected to the first piston of the cylinder, the other - to the second. The piston of the cylinder of the first row returns to top dead center, compared to the second row, 90 degrees earlier.

Cylinder order of twelve-cylinder engines

At any moment, expansion is carried out in three cylinders at once: it starts in one, then continues in the next and ends in the third. Due to this, a smaller change in the magnitude of the moment on the shaft is ensured and, accordingly, a greater uniformity of the stroke.

Operating order of star engine cylinders

The crankshaft has only one crank, which is connected toall rods. For example, the piston in the first cylinder is at the top dead center when the connecting rod and the crank knee are on the same straight line. The piston of the second comes to this point after the crankshaft rotates through an angle equal to the angle between the axes of the nearest cylinders. Uniform alternation of the stroke is possible only with an odd number of cylinders. Therefore, in such engines, the number is always odd, and not more than 11. If necessary, in a larger number of cylinders, they are arranged in several rows, while each of them is in the same plane, working on a common crank.

Recommended:

How to turn off ABS: the order of work. Anti-lock braking system

Almost every modern car has an anti-lock braking system. The main task is to prevent an accident during braking, when the car loses its stability. The device helps the driver to maintain control over the car and reduce the braking distance. Not all drivers liked this system. We have to think about the question of how to turn off the ABS, which is especially often of interest to experienced drivers

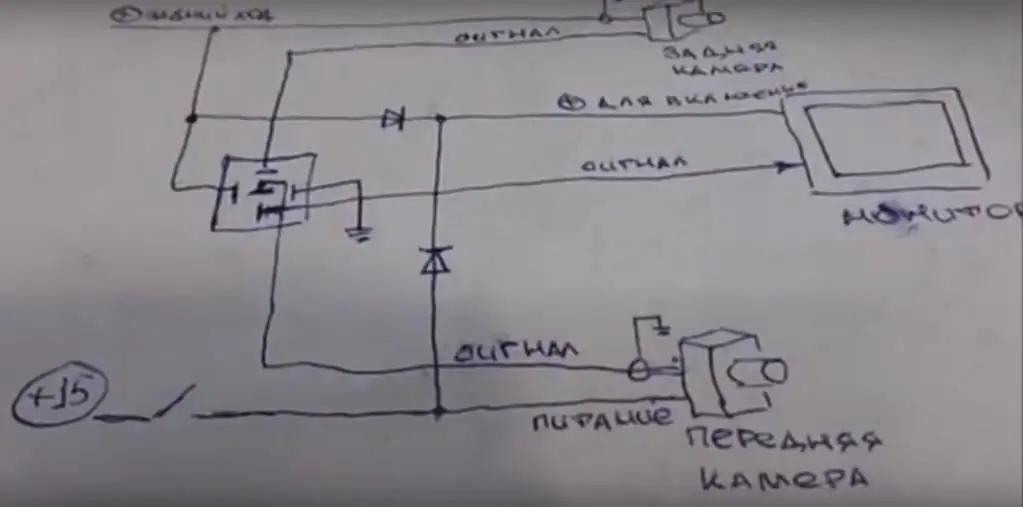

Rear view camera connection diagram: diagrams, work order, recommendations

The number of cars on the roads is growing exponentially. There are fewer and fewer parking spaces. At the same time, manufacturers are increasing the dimensions of passenger cars, thereby reducing their ability to maneuver in the parking lot. This leads to emergency situations when reversing. Installing a rear view camera on the car will help solve this problem

The order of bleeding the brakes and the main elements of the system

You need to know what order to bleed the brakes in order for the entire system to work as stably as possible. At the same time, it is important that not a single cubic millimeter of air remains in the tubes and hoses, because it is it that interferes with braking

MTZ-82: gear shifting scheme, mode switching order

Scheme and device of the MTZ-82 gearbox. The order of switching modes, photo, diagram. Features of switching modes of the MTZ-82 box

The best lubricant for brake cylinders

All vehicle systems must be in good working order during its operation. But special attention must be paid to the brakes. Indeed, often the life of the driver, passengers, other road users and pedestrians depends on the state of the brake system of the car. It needs to be serviced periodically. This consists in replacing brake pads, discs, fluid, as well as calipers. For example, lubrication for brake cylinders during their maintenance and replacement is simply necessary. We'll talk about all this