2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:17

Imported car is valued for its high quality characteristics. A person gets used to good things quickly, and Opel Astra has long become a supporter of many on Russian roads. Zvezda began its ascent to the international market in 1991. Since then, many restyled versions have been released. An understandable desire of any vehicle owner is a long-term relationship with his “swallow”, and German engineers have tried to make every effort and technology to satisfy the modern car user. So the Opel-Astra H sim-module is called upon to fulfill its own special “mission”.

Very often motorists in the German automotive industry have to face problems. One of them is the failure of the Opel Astra H SIM module, which, as usual, happens unexpectedly. Is it really possible to fix it or is it easier to simply replace the unit?

SIM module as the difference between Opel and other brands

A foreign car from a German concern is different from others"brothers" by this node. On this car, the developer did not turn to analog ignition, but preferred a digital version. Here you will not find abundantly pushed thick wires. Power, can-bus, a couple of wires - everything that sticks out of the cim-module. The work of turn signals, optics is carried out thanks to two wires.

The engineers also sewed into the design an analog ignition switch, a controller responsible for encoding analog signals into digital, but it is difficult to get to these contacts and only specialists can. In this regard, it is difficult for a beginner to repair the cim-module according to the Opel Astra logbook on Internet blogs, but it is quite possible to do this.

Main problem

One fine day, the "astrovod" notices that the buttons on the steering wheel refuse to fulfill their purpose. Auto mechanics consider the faulty Opel Astra H SIM module to be the cause of this behavior, urgent action must be taken. It's all about the design flaw of this device. In practice, the problem of the functioning of buttons, steering column switches is often encountered. This translates into the inability of the car to honk, flash turn signals, control the car radio.

What to look out for?

Disturbances along the way lead the driver to bewilderment, fright, make them panic. Why malfunctions haunt, how to deal with it? Often you have to fix the steering wheel cable of the SIM module on the Opel Astra, and in this case the main thing is to disassemble it correctly, carefully folding it into place. The bend of the loop, its incorrect laying lead tofailure of all buttons on the steering wheel. The main disadvantage of improper dismantling is that the airbag refuses to work. It is better to contact the service station masters to fix problems with the cable.

Dilemma: do it yourself or go to a service station?

There is a huge amount of information on the Internet, mainly on forums where the Opel Astra logbooks describe the repair of the SIM module in some detail. Auto mechanics operate according to a certain pattern:

- Soldering the contacts gives a good result.

- Has a positive effect of correcting the "ailments" of the plume.

- The installation of latches responsible for vibration reduction has a good effect on the functionality of the device.

- In other cases, it is effective to replace the Opel-Astra H SIM module with a new one.

After studying information from various sources, the owner of the car decides to carry out repairs with his own hands in order to save money. Placing too high hopes on his own knowledge, he does not get the expected result. As a result, the search for a new device begins, which is quite expensive.

Important moment

Replacement means flashing the product. TECH2, Carpass codes are successfully used for diagnostic procedures. In order to carry out a competent repair of the Opel Astra H SIM module, you need a good tool, experience in carrying out such work, so you should hardly neglect the help of professionals.

Step by step preparation

A certain sequence of repairs should be followedmanipulation.

First, the steering wheel has to be removed. This should be done with the negative terminal of the battery thrown off. How to properly remove the steering wheel? Here, the airbag initially interferes, it must be removed by turning the steering wheel 900 degrees. Next, you need to snap off the fasteners and two colored connectors from the pillow, pass them through the steering wheel.

Attention! The analysis of the pillow due to the presence of a squib is carried out very carefully!

What is visible in the niche now:

- Opens access to the signal button plate, which is made of metal.

- You can see a white-brown wire, it supplies power to the top plate.

- The bottom plate is "powered" by a brown cord.

Also visible is the screw holding the plate, the center steering wheel lock, the main connector responsible for the operation of the buttons on the steering wheel and the spring of the Air Bar latches.

The essence of the further algorithm

Wheels need to be put straight. We unscrew the fasteners at the plates, disconnect the signal button harness connector. The electrical wires also need to be disconnected. Next comes the lining of the plastic casing, the ring is removed. You will have to dismantle the control unit on the back of the column. Then lift the detachable holder and unfasten it.

The helm position mark will be a mandatory further condition. You should also unscrew the middle fasteners, and the steering wheel can already be easily pulled out. Finally, you can begin to "treat" the device by dismantling the modular device, attached with three screws, from the steering mechanism.

When diagnosingthe causes of defects with the modular system in insufficient contact of the snail cable, the servicemen clean and bend the detachable "antennae". In some situations, they turn to the method of duplicating the connector with a wire loop prepared in advance.

About some nuances

Prior to the procedure, the service shop uses diagnostic equipment to locate problem areas. It is common practice to solder the microelement circuit of the board or connectors. Constant vibrations, large loads with temperature differences provoke deterioration of detachable contacts. In order to ensure the reliability of the pins, it is optimal to resort to a thin layer of KBT paste.

The method of duplicating connectors in the repair of the cim-module on the Opel-Astra is justified if incorrect operation of the turn signals in the operating mode is detected. Factory conductive paste burns due to exposure to contact sparks. As a result, grip deteriorates or this leads to its complete loss. To eliminate this mechanical trouble, the worn paste is removed and a new version designed for electrical contacts is used.

After reassembling the structure, the steering wheel is set to the "zero position". The OP-COM adapter helps to do this. The "mission" of this microprocessor is to synchronize the PC with the OBD connector of a foreign car. Thanks to a special program, he manages to recognize the true state of affairs in the iron horse's electronic system.

A couple of words in pursuit

Any procedureswhether it is diagnostics or repair, in relation to the cim-module scheme, they need the participation of experienced, highly qualified specialists, competent tools. If you are not sure of your technical abilities, then it is better to contact a car repair shop. Faulty equipment becomes the culprit of the driver's insecure feeling on the road, causing accidents. At the very first "bells" that disturb the soul and the car, we advise you not to delay, promptly responding to the current situation.

Recommended:

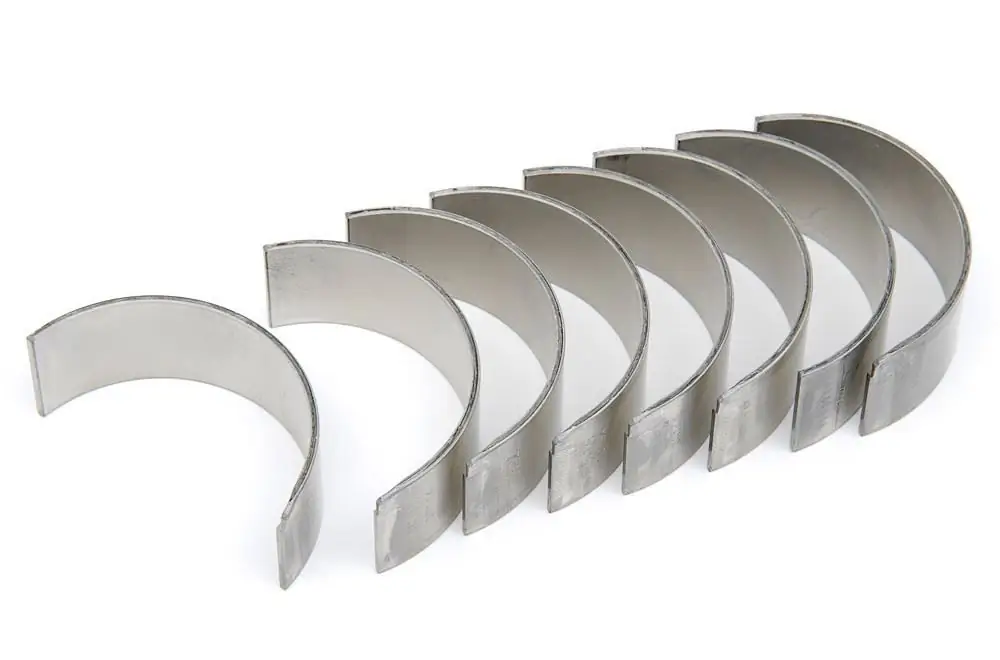

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

Yamaha XT 600: specifications, top speed, operation and maintenance features, repair tips and owner reviews

The XT600, developed in the 1980s, has long been considered a legendary model by the Japanese motorcycle manufacturer Yamaha. A highly specialized enduro over time has evolved into a versatile motorcycle designed to travel both on and off the road

Repair and painting of a car body: features, technology and reviews

The body of a car is essentially its supporting structure. He is constantly under pressure. Moreover, these are not only mechanical factors in the form of shocks and vibrations. Every day, the coating of the body is exposed to the negative effects of external factors. Enamel is sandblasted, burns out. In addition, traces of rust appear at the site of deep scratches. Of course, all this significantly spoils the appearance of the car. But what to do?

N52 engine: features, device, repair and reviews

The N52 BMW engines went into production in 2005. At that time it was a fundamentally new generation of engines. According to the layout scheme and the temperature control mode, this is a “hot” power unit. We will study its advantages and disadvantages, as well as the recommendations of specialists in its maintenance

Exhaust system VAZ-2109: purpose, device, technical characteristics, features of operation and repair

VAZ-2109 is perhaps the most famous Russian-made car. This car has been produced since the days of the USSR. It was the first car where the torque was transmitted to the front rather than the rear wheels. The car is very different in design from the usual "classics"