2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:18

The depletion of hydrocarbon fuels, environmental degradation and a number of other reasons will sooner or later force manufacturers to develop models of electric vehicles that will become available to the general population. In the meantime, it remains only to wait or develop options for environmentally friendly technology with your own hands.

If you still prefer to look for solutions on your own, rather than waiting for them from outside, then you will need to know which electric car engines have already been invented, how they differ and which one is the most promising.

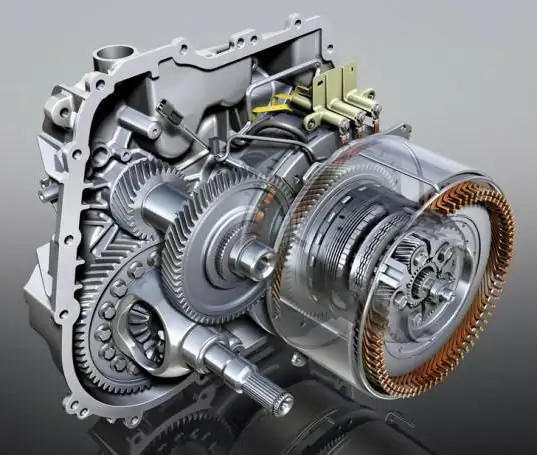

Traction motor

If you decide to put an ordinary electric motor under the hood of your car, then most likely nothing will come of it. And all because you need a traction electric motor (TED). It differs from conventional electric motors in greater power, the ability to deliver more torque, small dimensions and low weight.

ForBatteries are used to power the traction motor. They can be recharged from external sources (“from the socket”), from solar panels, from a generator installed in the car, or in recovery mode (self-replenishment of the charge).

Motors for electric vehicles are most often powered by lithium-ion batteries. TED usually operates in two modes - motor and generator. In the latter case, it replenishes the spent supply of electricity when switching to neutral speed.

Working principle

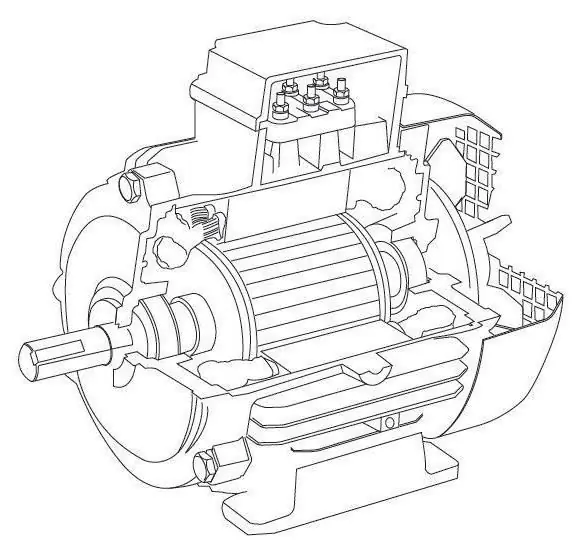

A standard electric motor consists of two elements - a stator and a rotor. The first component is motionless, has several coils, and the second performs rotational movements and transfers force to the shaft. An alternating electric current is applied to the stator coils with a certain periodicity, which causes the appearance of a magnetic field, which begins to rotate the rotor.

The more often the coils turn on and off, the faster the shaft rotates. Two types of rotor can be installed in motors for electric vehicles:

- short-circuited, on which a magnetic field arises opposite to the stator field, due to which rotation occurs;

- phase - used to reduce the starting current and control the speed of rotation of the shaft, is the most common.

In addition, depending on the speed of rotation of the magnetic field and the rotor, motors can be asynchronous and synchronous. One or another type must be chosen from the available funds and tasks.

Synchronousengine

A synchronous motor is a TED, in which the rotor rotation speed coincides with the magnetic field rotation speed. It is advisable to use such motors for electric vehicles only in cases where there is a source of increased power - from 100 kW.

One of the varieties of synchronous electric motors is a stepper motor. The stator winding of such an installation is divided into several sections. At a certain moment, current is supplied to a certain section, a magnetic field arises that rotates the rotor at a certain angle. Then the current is applied to the next section, and the process is repeated, the shaft begins to rotate.

Asynchronous electric motor

In an asynchronous motor, the speed of rotation of the magnetic field does not match the speed of rotation of the rotor. The advantage of such devices is maintainability - spare parts for electric vehicles equipped with these installations are very easy to find. Other benefits include:

- Simple design.

- Easy maintenance and operation.

- Low cost.

- High reliability.

Depending on the presence of a brush-collector unit, the motors can be commutator and commutatorless. A collector is a device that converts AC to DC. The brushes are used to transfer electricity to the rotor.

Brushless motors for electric vehicles are lighter, more compact and more efficient. They are less commonoverheat and consume less electricity. The only disadvantage of such an engine is the high price of the electronic unit, which acts as a collector. In addition, spare parts for electric vehicles equipped with a brushless motor are more difficult to find.

Electric Motor Manufacturers

Most homemade electric vehicles are designed using a commutator motor. This is due to availability, low price and easy maintenance.

A prominent manufacturer of these motors is the German company Perm-Motor. Its products are capable of regenerative braking in generator mode. It is actively used to equip scooters, motor boats, cars, electric lifting devices. If Perm-Motor engines were installed in every electric car, their price would be much lower. Now they cost between 5-7 thousand euros.

A popular manufacturer is Etek, which is engaged in the production of brushless and brushed commutator motors. As a rule, these are three-phase motors operating on permanent magnets. Main advantages of installations:

- control accuracy;

- ease of organization of recovery;

- high reliability due to simple design.

The list of manufacturers is completed by the Advanced DC Motors plant from the USA, which produces collector electric motors. Some models have an exclusive feature - they have a second spindle, which can be used to connect to an electric caradditional electrical equipment.

Which engine to choose

So that the purchase does not disappoint you, you need to compare the characteristics of the purchased model with the requirements for the car. When choosing an electric motor, they are primarily guided by its type:

- Synchronous installations are complex and expensive, but they have an overload capacity, they are easier to control, they are not afraid of voltage drops, they are used at high loads. They are installed on the Mercedes electric car.

- Asynchronous models are low cost, simple device. They are easy to maintain and operate, but their power output is much less than that of a synchronous plant.

The price of an electric car will be much lower if the electric motor is paired with an internal combustion engine. On the market, such combined plants are more popular, since their cost is about 4-4.5 thousand euros.

Recommended:

Electric pump for warming the car interior. "Gazelle", electric pump: characteristics, repair, connection, reviews

Most modern cars use an electric pump to provide cooling. "Gazelle" is equipped with an excellent device of this type, which can be installed on other cars

Toyota electric vehicles: overview, features, advantages and disadvantages

We all know how cars pollute the environment. To remedy the situation, new euro environmental standards are being introduced, which makes it possible to reduce the amount of harmful substances in the exhaust of modern cars. However, the problem can be completely solved with the help of electric vehicles from Toyota, Mercedes and other companies. Active work in this direction has been going on for a long time, and the first samples of such transport appeared in the 19th century

Can I mix synthetics and synthetics from different manufacturers? Is it possible to mix synthetics with synthetics from different manufacturers?

Quality lubrication is the key to reliable and long engine operation. Often, car owners brag about how often they change the oil in their car. But today we will not talk about replacement, but about topping up. If in the first case there are no questions (leaked, filled and drove off), then in the second case, the opinions of motorists differ. Is it possible to mix synthetics and synthetics from different manufacturers? Some say it's possible. Others say it's strictly forbidden. So let's try to figure this out

Electric vehicles in Russia: pros and cons

Today, electric vehicles in Russia are represented on the car market by only three models: Mitsubishi i-MiEV, VAZ Ellada, Edison van or Ford Transit. Other well-known manufacturers are not yet in a hurry to export their electric cars to Russia. Therefore, the question of where to buy an electric car is largely difficult

Electric scooter - reviews. Electric scooter for adults. Electric scooter for children

No matter which electric scooter you choose, it will allow you to enjoy relaxing walks in the park or immerse yourself in the world of outdoor activities