2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

The design of the car uses many systems - cooling, oil, injection and so on. But few people pay attention to the exhaust. But it is no less important component of any car. Over the years, the design of this system has been improved. We will talk about what the exhaust system of a car consists of and how it works in our today's article.

Destination

As you know, the mixture ignites in the engine during operation. This ignition is accompanied by a characteristic sound. During the explosion, a colossal pushing energy is generated. It is so large that it is able to raise the piston to top dead center. In the last cycle of operation, gases are released. They are released into the atmosphere under pressure. But what is an exhaust system for? It serves to dampen sound vibrations. Indeed, without it, the work of even the most technologically advanced motor would be loud and unbearable.

Thus, the exhaust system performs the following functions:

- Removal of combustion products from the engine cylinders.

- Reducing the level of toxicity of gases.

- Exclusion of combustion products from entering the car interior.

Device

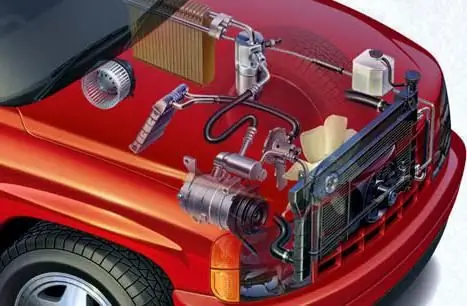

This system combines several components. In addition, it is directly related to the work of the timing. So, the classic VAZ exhaust system consists of:

- Front pipe.

- Catalyst.

- Resonator.

- Muffler.

- Various fasteners and sealing elements.

- Oxygen sensor.

If we consider diesel cars, then the design will also have a particulate filter. What are all these elements? The device of each of them will be considered below.

Downpipe

This item is the first item on the list and comes right after the exhaust manifold. Gases that have not yet cooled down enter the intake pipe. Therefore, the temperature can reach 600 degrees Celsius or more. In the common people, the downpipe is called "pants" for its characteristic shape.

This element is made of highly durable and fire-resistant metal. Usually it is rough (it rusts over the years), but on more expensive cars it is made of stainless steel. If it is an engine with a large combustion chamber volume, several of these tubes can be used in the system design. This is done in order to reduce the resistance of gases. Otherwise, the motor will "suffocate" with its own gases.

Resonator

It is made in the shape of a cylindrical can. It is in the resonator that the first separation of the exhaust gas flow occurs. Also, by increasing the diameter, the speed of the exhaust movement decreases.

Gasesgradually dissipate in this chamber. Due to this, vibrations and partially sound are damped. Just like the "pants", the resonator is made of fire-resistant metal.

Catalyst

This is probably the most complex and expensive part of any exhaust system. The body of this element is also made of fire-resistant metal. However, unlike the resonator and receiver pipe, it is multilayered. Inside this "jar" there is a ceramic rod. Additionally, the catalyst is equipped with a wire mesh. It covers the second piece of ceramic material.

In addition, the device has a layer of thermal insulation with double walls. Why is a catalyst so expensive? In addition to ceramics, expensive materials are used here - palladium or platinum. It is these components that convert harmful gases into hydrogen and safe vapors. In view of this, the minimum cost of a new neutralizer is 40 thousand rubles.

Particulate filter

If we consider the structure of the exhaust system of a diesel engine, this element is worth noting. It is an addition to the catalytic converter. The filter is based on a matrix made of silicon carbide. It has a cellular structure and has channels of small cross section. The latter are alternately closed on one side and the other. The side of the element plays the role of a filter and has a porous structure.

Until recently, matrix cells had a square shape. Manufacturers now use octagonal cells. This is how you get the best grip.soot and its settling on the walls of the filter.

How does this item work? The particulate filter operates in several stages. The first step is to filter the soot. Gases enter the element, and harmful substances settle on the walls. The second stage is regeneration. She can be:

- Passive.

- Active.

In the first case, harmful gases are purified by passing through the ceramic element. In the second, a special liquid is added - AdBlue. Usually such a system is used on trucks. It reduces emissions by up to 90 percent. The car has a separate tank for this liquid, and the system, after receiving the appropriate signal, injects part of the AdBlue into the catalyst. So, almost clean exhaust comes out of the pipe, containing hydrogen that is harmless to the atmosphere.

Lambda probe

It is also called an oxygen sensor. It is installed near the catalyst in a threaded connection. It is a sensitive element that comes into contact with exhaust gases.

The task of the sensor is to determine the temperature of gases and the presence of oxygen in them. Based on the read data, the ECU sends a signal to the intake manifold. If necessary, an additional portion of fuel is injected into the cylinders. What is it for? The fact is that the catalyst fully works only under the condition of elevated temperatures (at least 600 degrees). If the gases are colder, no filtration or conversion will take place. So the system addsmore fuel so that the temperature of the catalytic rod is in the operating range. This system has practically no effect on fuel consumption (provided it is in good condition).

Silencer

This is the last element in the system. Silencers come in two types:

- Standard.

- Sports.

The first are installed on all civilian vehicles. The design of such a silencer involves the presence of several metal partitions. Also in the body there is a perforated pipe through which gases are directed from one partition to another. According to this scheme, the greatest reduction in the level of noise and vibration is made. The factory muffler is made of refractory metal. However, practice shows that its service life is an order of magnitude less than that of sports ones. The reason for this is the lack of a nickel-plated surface and too thin metal of the insides.

As for sports mufflers, they have a simpler design. It is a straight perforated tube with an expansion in the middle and filled with glass wool. The exhaust pipes of this type of muffler are very large. As a rule, on co-currents, the diameter of the exhaust hole is one and a half to two times higher than that of standard ones. Thanks to this, fast venting of gases and good "exhaust" are produced.

But why are these mufflers not installed on cars from the factory (except for sports versions)? It's all about the level of their noise. As practice shows, such mufflers practically do not struggle with the damping of sound vibrations. Their task is to takethe largest possible flow of gases in the shortest possible period of time. On the move, these mufflers make a hum, and when they pick up speed, they begin to “yell” even louder. Therefore, direct currents are not suitable for everyday comfortable driving. Although their design is more reliable and practical than that of their “civilian” counterparts.

Sealing elements

So, we have listed the main components of the exhaust system and their design. However, we have not talked about how they connect to each other. Fasteners are made on bolts and clamps. The downpipe is connected to the exhaust manifold and resonator on two gaskets. Depending on the type of vehicle, the gasket can be made of pressed corrugated foil or solid metal. Additionally, a washer can be used. As for the muffler itself, it is connected to the resonator thanks to a clamp, with an overlap. On some machines, a ring can be used (for example, on the domestic "eight"). For better sealing, experts recommend using a heat-resistant sealant (up to 1100 degrees). It perfectly seals all gaps and prevents gases under pressure from escaping ahead of time.

Exhaust system malfunctions

The main symptom is the characteristic sound of gas removal. The car starts to “yell”, an unpleasant smell of gasoline or diesel appears in the cabin. Also, the car stops running normally. And if the exhaust manifold gasket is burned out, the “Check” will light up on the instrument panel. It indicates that the oxygen sensor is not working properly. Along with this, fuel consumption also increases (because the system cannotaccurately dose fuel, as before). The way out is to replace the exhaust manifold gasket. Also inspect the condition of the pipes themselves. If they begin to rot or there are cracks at the joints, an exhaust system repair is required. The rot is cut out with a grinder and a new sheet of metal is welded on. But as practice shows, a more practical and faster way is to replace an obsolete element with a new one. Remember that the muffler is a consumable item. After 2-3 years, it must be replaced. The same applies to other elements, but their resource is slightly longer. For example, "pants" burn out after five years of operation.

About corrugation

Exhaust system (including direct-flow) may also include corrugation. It is an additional damping element. Thanks to it, the load on other parts of the exhaust system is reduced. The sound of gas escaping becomes quieter. But it is worth noting that the corrugation in the exhaust system is the lowest element. Because of this, owners often damage it.

Corrugation cannot be repaired. It is changed or a piece of a new pipe is welded in its place. As practice shows, the noise level practically does not increase after such repairs. The main thing is to achieve maximum tightness in the sealing elements. After all, a burnt gasket can be a serious cause of deterioration in vehicle performance.

Conclusion

So, we examined the structure of the exhaust system and its main malfunctions. Finally, let's give a little advice. When removing sootfilter or catalytic converter, it is worth taking care of removing the oxygen sensor. If this is not done, the engine will “overflow” - fuel consumption will increase and an error will light up on the instrument panel. After removing the catalyst (it is changed to a flame arrester), a new firmware is uploaded to the ECU. And a plug is installed in place of the sensor.

Recommended:

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

Car air conditioning system: diagnostics, repair, flushing, cleaning, system pressure. How to flush a car's air conditioning system?

The warm season is accompanied by frequent requests from car owners to service shops for such a service as diagnostics of the car's air conditioning system, as well as troubleshooting. We will understand the reasons for this phenomenon

Planetary gearbox: device, principle of operation, operation and repair

Planetary gears are among the most complex gear boxes. With a small size, the design is characterized by high functionality, which explains its widespread use in technological machines, bicycles and caterpillar vehicles. To date, the planetary gearbox has several design versions, but the basic principles of operation of its modifications remain the same

Exhaust system VAZ-2109: purpose, device, technical characteristics, features of operation and repair

VAZ-2109 is perhaps the most famous Russian-made car. This car has been produced since the days of the USSR. It was the first car where the torque was transmitted to the front rather than the rear wheels. The car is very different in design from the usual "classics"