2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Everyone knows that the main task of the engine is to generate the torque needed to set the wheels in motion. However, not everyone is aware of exactly which devices and mechanisms are involved in this way, so that the moment is transferred from the flywheel to the rim itself. Depending on the design of the car, different systems can be used here. However, they have the same name - cardan transmission. Let's consider its purpose, types and features right now.

Description

So, what is this element used for? It serves to transmit torque between shafts that are at a specific angle relative to each other. As a rule, such a transmission is used in transmission units.

It connects the following elements:

- Engine and gearbox.

- Gearbox and transfer case.

- Transmission and final drive.

- Drive wheels and differential.

- Transfer transmission and final drive (found on SUVs).

As you can see, a node can interact in different mechanisms and units.

Hinge

This is the main element in the driveline device. What types does it have? At the moment, there are several types of cardan gears, depending on the design of the hinge:

- With CV joint.

- With SHRUS.

- With semi-cardan joint. It can be elastic or rigid. Not currently used in vehicles.

So, let's look at these species in more detail.

Gear with unequal angular velocity joint

It consists of the following elements:

- Sliding fork shank.

- Intermediate shaft.

- The fork itself with a mud deflector.

- Protection ring.

- Intermediate support.

- Bearing.

- Lock washer and A-plate.

- Spline plug.

- Cross.

- Rear shaft.

- Final drive flange.

- Gimbal.

- O-ring.

- Stop with bolt.

- Needle bearing.

Such a transmission in the common people was called "cardan". It is used on cars with rear or all-wheel drive. These are mostly SUVs or commercial vehicles. A similar cardan transmission is also used on VAZs of classic models. This node includesthemselves hinges of unequal angular velocities. They are located on cardan shafts. In some vehicles, an intermediate support with a bearing may be used (usually when the cardan consists of two parts). At the ends of this transmission there are connecting devices (flanges).

Such a hinge consists of two forks, which are located at an angle of 90 degrees. The crosspiece rotates due to the needle bearing, which is installed in the eyes of the forks. These bearings are maintenance free. Thus, the grease that is under the covers is pressed in for the entire service life and does not change during operation.

Among the features of this type of mechanisms, it is worth noting the following. The transfer of forces is carried out unevenly (cyclically). So, in one revolution, the driven shaft overtakes the drive twice and lags behind twice. To compensate for uneven rotation, at least two hinges are used in this assembly. They are located one on each side of the driveline. And the forks of opposite hinges rotate on the same plane.

If we talk about the number of shafts, there may be several or one. It all depends on the distance over which power will be transmitted to the main gear of the car. When using a two-shaft scheme, the first shaft is intermediate, and the second is rear. An element created according to this principle necessarily provides for the presence of an intermediate support. The latter is attached to the frame of the car (or, in the absence of such, to the body). To compensatechange in the length of the transmission, a spline connection is made in the first or second shaft. The mechanism interacts with the transmission elements (gearbox and rear axle) through a coupling and flanges.

Transmission with CV joint

Now this design is the most popular and practical in the world of cars. Often a similar scheme is practiced on front-wheel drive vehicles. The main purpose of this transmission is to connect the drive wheel hub and differential.

Structurally, this node consists of the following elements:

- Half shafts.

- Collar.

- Clips.

- Hinge housings.

- Separator.

- Retaining ring.

- Sharik.

- Cone ring.

- Spring washer.

- Splash cover.

This transmission includes two hinges. They are interconnected by a drive shaft. The CV joint closest to the transmission is internal, and the opposite (on the side of the drive wheel) is external.

Also, a similar scheme for using hinges is practiced on rear- and all-wheel drive vehicles (a vivid example of this is the domestic Niva). The use of such a scheme can significantly reduce the noise level during transmission operation. Compared to crosses, the CV joint is a more modern design and provides a much greater torque transmission at a constant angular velocity.

About SHRUS

The CV joint itself is a clip, which is placed in a special case. Between the clips moving metalballoons. The body is spherical. Grooves are made in it for the movement of balls. This design allows you to transmit torque at an angle of 30 degrees or more. The design also uses a separator that holds the balls in a certain position.

Dustcoat

Separately, it is worth mentioning the anther. This mudguard is an indispensable element, without which the operation of the CV joint is not possible. This boot is attached with clamps and prevents dirt, dust and other deposits from entering the case. During operation, you must always monitor the condition of the dirt-protective cover. Otherwise, dust and water will destroy the hinge structure and wash out the lubricant.

Due to increased wear, the grenade may soon crackle. Repair of the driveline will not allow you to return it to its previous, working condition. With such signs, the element changes entirely to a new one. We also note that in the manufacture of the CV joint, a lubricant based on molybdenum disulfide is placed inside. It is laid down for the entire service life of the CV joint. And in case of damage to the anther, when replacing it, the lubricant also changes.

With semi-cardan joint

Rarely used now. Such cardan transmission consists of the following elements:

- Insert.

- Centering sleeve.

- Elastic element.

- Gearbox output shaft flange with bolt.

- Gland with cage.

- Output shaft.

- Dirt deflector.

- Drive shaft.

- Mounting nutsflange.

- Centering ring.

- Traffic.

- Center ring seal.

How does this knot work? This mechanism transfers forces between two shafts, which are at a small angle, due to the deformation of the elastic element. Often in such a scheme, the Guibo coupling is used. It is a hexagonal elastic element. The coupling is flanged on both sides to the driven and driving shaft.

Conclusion

So, we found out what types there are and how the cardan drive of a car is arranged. The most popular and perfect today is the transmission on CV joints. However, there are still cars that use an old cardan on crosses that has been proven over the years. This is especially true for commercial vehicles. This design is the main one for trucks, buses and special equipment.

Recommended:

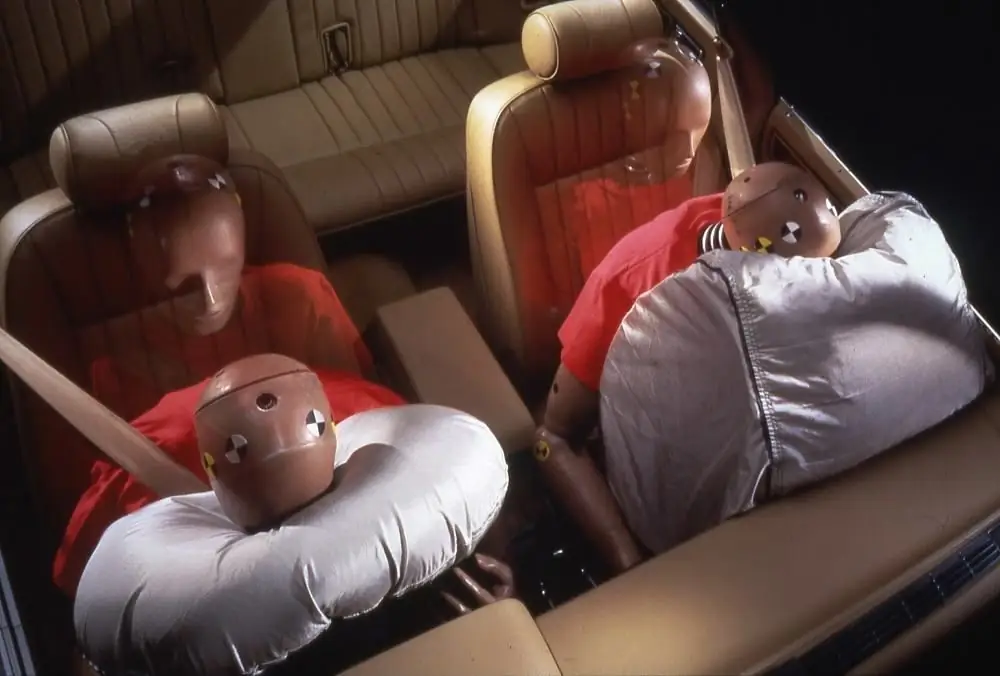

How airbags work in a car: device and principle of operation

Modern cars are equipped with many protective systems, including airbags. They allow you to avoid serious consequences for the driver and passengers (depending on the configuration). Moreover, their number varies from 2 to 7 pieces, but there are models where there are 8, 9, or even 10 of them. But how does an airbag work? This will be of interest to many motorists, especially inquisitive individuals who want to be well versed in their car

Rear-wheel drive car: description, device, pros and cons

Currently, there are cars with different types of drives. These are front, full and rear. When choosing a car, the future owner should know the features of each. Most professional drivers prefer to buy a rear-wheel drive car. What are its features? We will talk about this in our article

Rating of active foam for car washing. Foam for washing the car "Karcher": reviews, instructions, composition. Do-it-yourself car wash foam

It has long been known that it is impossible to clean a car from heavy dirt with plain water. No matter how hard you try, you still can't achieve the desired purity. In order to remove dirt from hard-to-reach places, special chemical compounds are used to reduce surface activity. However, they also cannot reach very small cracks and corners

Car "Marusya" - the first domestic sports car in the history of the Russian car industry

The Marusya sports car dates back to 2007. It was then that VAZ was offered the idea of creating the first racing car in Russia

How to “light up” a car from a car? How to “light up” an injection car?

Probably every driver has faced such a problem as a dead battery. This is especially true in winter cold. In this case, the problem is most often solved by "lighting up" from another car