2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-06-01 05:35:55

Refrigerated car is a universal covered structure designed for transportation of perishable goods. The refrigeration unit allows to preserve the quality of the transported goods. This category of equipment is included in the class of isothermal rolling stock, mainly used to transport food over a distance of more than 500 kilometers.

Description

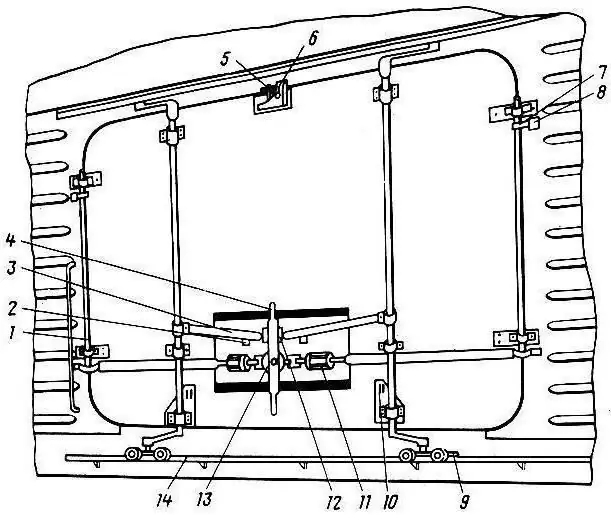

The refrigerator car consists of an all-metal body, a center beam, and a heat-insulating layer. This transport differs from other analogues in the presence of automatic cooling and electric heating. Freon or ammonia is used as a refrigerant for refrigeration equipment, as well as energy produced by diesel generators. Heating is provided by electric stoves. In addition, the design of the car includes a system of forced ventilation and air circulation in the cargo compartment.

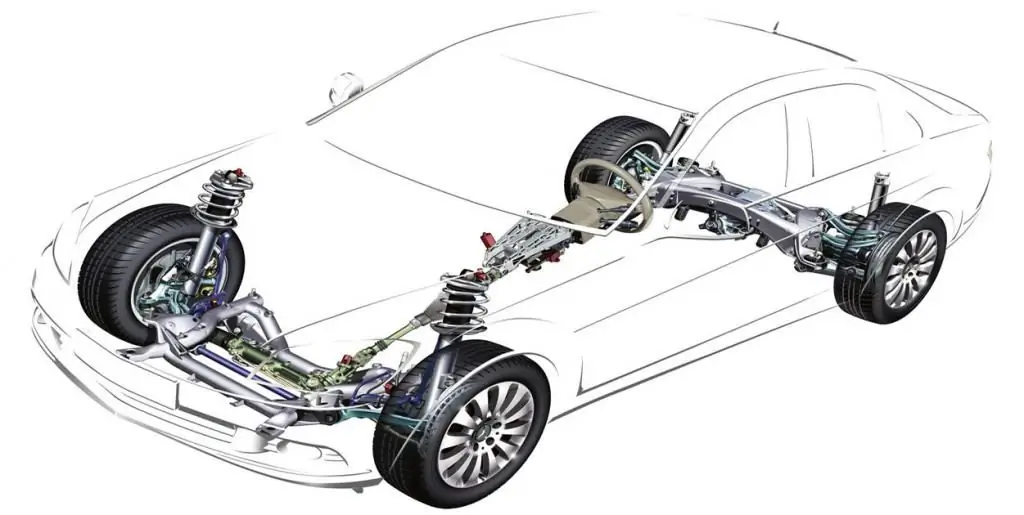

The running unit is jawless bogies with a pair of axles, which are equipped with axle boxes with roller bearings and UVZ-I2 modification springs with a base of 2400 mm. The classification of such rolling stock is carried out according to several parameters:

- Composition of the train (number of cars).

- Standalone variations.

- Type of coolant used.

In the case of group ammonia plants located in the central car of the train, the refrigerant is supplied by transferring the mixture through special channels. In the stand-alone version, cooling is carried out in each unit separately.

Refrigerated car: specifications

The following are the parameters of the considered rolling stock with a base length of 21 meters (in brackets are the indicators for the version with a body of 19 m):

- Length along the axes of automatic couplers - 22, 08 (22, 08) m.

- External body width - 3, 1 (3, 1) m.

- Height limit from the rail head - 4, 74 (4, 69) m.

- Length/width/height of the loading bay in meters - 17, 6 (15, 7)/2, 7 (2, 7)/2, 1 (2, 2).

- Total volume of the cargo part - 113 (102) cubic meters. m.

- Floor area (full) - 48, 1 (42, 6) sq. m.

- Capacity indicator - 36 (40) tons.

- Height of the floor grating - 102 (102) mm.

- Equipped container - 48 (44) t.

The refrigerated car, the dimensions of which are given above, is equipped with a special door. Its width and height are two meters for both types of structures.

Standalone option device

Standalone version equipped with automatic refrigeration and energy devices. It is divided into a cargo compartment and two engine rooms at the ends. Diesel generator and fuel tank are installed on oneretractable frame, which makes it possible to remove the unit through the side entrance to the technical department.

The heating unit operates on liquid fuel, which makes it possible to warm up the diesel engine before starting at low temperatures. The generator has a switchboard that serves to control and monitor instrument automation.

Refrigerating equipment is located under the roof of the car, separated by a partition between the cargo area. In addition, an individual refrigerated car is equipped with an air cooler, fans, electric heaters, a compressor and condensate device with a shield. The refrigerator, if necessary, can be dismantled through the end door.

Features

One of the engine rooms is equipped with a main switchboard. It is located next to the fuel tank and serves to control the operation of the equipment and regulate the thermal conditions in the body. The cold air is fed by electric fans to the part between the roof and the false ceiling, then through the provided slots it enters the cargo compartment.

Air covers the load and moves to the vertical channel through the floor grates, is taken in by fans, bypasses the air cooler, is blown back into the workspace. In a similar way, circulation occurs during heating. Instead of cooled air, a mixture heated by electric furnaces passes through the system. To remove excess air mass, special deflectors are provided. Condensate and waterdisposed of by drain holes in the floor. The self-contained railway refrigerated car is equipped with a flying electrical system designed to control the EPT (pneumatic brake). This design makes it possible to use transport in passenger trains. The parking brake provides additional security.

Group variety

The rolling stock of this group consists of a refrigeration station located in a separate car, a diesel and electrical substation, and a service compartment. Cold is generated by ammonia plants and transferred to other cars through the brine system. Pre-cooled liquid circulates through special batteries. It is processed in the engine room.

Heating is carried out by turning on electric stoves mounted in the end parts of the body. The average power of each heating element is 4 kW. The devices are switched on automatically by means of a thermostat or from a central control point located in the equipment box.

Air circulation

Under the ceiling there are channels for exhaust air. The mixture is circulated by means of electric fans. They are provided in the end parts of the body. Refrigerated cars, the photo of which is placed below, have a control panel, from where the operation of the diesel plant is adjusted and the necessary temperature conditions are maintained. Deflectors remove excess air, the inner lining of the sidewalls is made ofcorrugated galvanized, flooring finished with rubber, there are metal gratings that can be lifted and fixed in a vertical way.

About sections

BMZ production sections consist of 4 refrigerators, each of which has an engine compartment with a pair of refrigerators operating on freon. The middle car is equipped with diesel generators and the main switchboard. The total volume of the composition is from 160 to 200 tons.

Analogues of the ZB-5 type (GDR) have four freight cars and one diesel car. It contains generators, an additional control cabin, technical rooms for personnel. Each section is maximally unified, including the parameters of the frame, walls, roof, equipment. Refrigeration units operate by switching on and off with automatic pulse signals after selecting the required thermal mode. The possibility of manual control of devices by means of control from a cabin of a diesel car is provided. Thermostats allow you to maintain the set temperature, refrigerators are powered by diesel through plug-in connections at the ends of the walls. The refrigerator car is equipped with a corrugated galvanized steel body. Some modifications have a sandwich construction.

ZA category sections also include five cars, one of which is equipped with a service compartment and a power plant. Larger variations consist of 12 cars (10 refrigerators and a couple of technical models).

Domestic producers

The most used refrigerators on the Russian Railways are modifications from two manufacturers. The Bryansk Machine Building Plant first produced a refrigerated car, the characteristics of which are given above, in 1965. Production continued until 1990

During this time, several models have been developed:

- RS-5 is a refrigeration section of 5 wagons, which allows maintaining the temperature regime of the transported cargo from -20 to +14 degrees Celsius. The diesel car in this section is type 376.

- Two-chamber section under index 16-3045. The design allows you to store two types of different products, thanks to separate chambers that can be set to different temperatures.

Another well-known manufacturer of the cars in question worked in the former GDR. FTD Fahrzeugtechnik Dessau AG produced refrigerated trains for the CMEA states. This included five-car sections ZA-5, ZB-5, as well as autonomous modifications (ARV and ARVE).

Finally

Given that the weight of the refrigerated wagon is 209 tons, its maintenance requires special attention. As a rule, each unit is accompanied by a technical team. Her responsibilities include looking after the condition of the equipment, regularly checking it, setting the thermal regime, turning on the necessary thermostats and other devices.

Usually, each train is served by two crews, which change every 45 days. Reception and delivery of the composition are carried out in an empty state(The exception is special cases by order of the head of the depot). The composition of the brigade is established at the direction of the Russian Railways. As a rule, this is the boss and a couple of mechanics.

Recommended:

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

What type of car is the best. The main types of cars and trucks. Car fuel types

Life in the modern world is unimaginable without various vehicles. They surround us everywhere, almost no industry can do without transport services. Depending on what type of car, the functionality of the means of transportation and transportation will be different

What is the difference between refrigerated semi-trailers and others?

Refrigerated semi-trailer is one of the types of heavy-duty trailers that are designed to transport goods that require special temperature conditions. Such cargoes include meat, seafood, alcoholic beverages (wine in particular), medicines, flowers and semi-finished products. Modern refrigerated semi-trailers are equipped with refrigeration units capable of cooling the cargo compartment to a temperature of minus 20-30 degrees

Types of car tires by season, design, operating conditions. Types of car tire treads

Car tires are an integral part of any car, which seriously affects the grip and safety of the driver. It is very important to choose exactly the model that is suitable for your car and will meet all the requirements of the manufacturer. This article talks about the types of car tires (with photo), their marking and operating conditions