2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

The starter stops performing its functions when the solenoid relay fails. Unlike other devices of a similar purpose, it not only closes an electrical circuit with its contacts, but also provides mechanical engagement of the bendix and the flywheel crown for the duration of the engine start. Such a dual purpose is not, perhaps, more than one node of the car. Given the importance of the starter solenoid relay for the normal operation of the machine, knowledge of its purpose and device will not be superfluous at all, and the repair theory will certainly come in handy in practice.

Device

Structurally, the traction relay, that's what it is called in all manuals, is a powerful electromagnet. It differs from most solenoids by the presence of two windings, retracting and holding. The relay has powerful, normally open contacts and a stem on which a metal plug is fixed.

The retractor is made in the form of a complete, independent unit and installed on the starter. The relay body is cylindrical, made of metal. On the back, it is covered with a liddielectric material, on which 3 terminals are fixed. Two of them are designed to power the starter, the third is the solenoid winding of the relay. The case can be either collapsible or not, depending on the manufacturer and model. The starter solenoid relay is returned to its original position by a powerful spring.

Working principle

Why do you have to install a traction relay? The fact is that the starter consumes a lot of current. These are tens or even hundreds of amperes in full braking mode. Therefore, it will not work to connect it directly to the ignition switch, its contacts will immediately burn out. You need to use an additional relay. It must have powerful contacts, which means a large power consumption, which will create an additional load on the battery. In addition, questions would arise with the connection of starter wires with a large cross section. The starter solenoid relay, due to its design, is free from these shortcomings.

Now directly the principle of operation. When the ignition key is turned to the position that includes the starter, a positive is applied to the retracting winding. The relay is activated and closes the starter power circuit with its contacts. But that's not all. Structurally, it is done so that the retracting winding is connected in series with the starter. This prevents excessive current consumption at the first moment. Then the retracting winding is shunted by its own contacts and turned off, and the relay remains in operation thanks to the retaining one. It is not as powerful, which means it consumes less current. Due to the fact that the retractor is installed directly on the starter,managed to solve the problem with the connection, it took only one long wire with a large cross section.

Simultaneously with the electrical part, the mechanical part of the relay also starts to work. The retractor rod moves back along with the core. At the same time, the fork moves forward, the bendix engages with the ratchet ring. The starter starts turning the engine crankshaft.

Faulty retractor

All damage to the traction relay is usually associated with long-term operation and large mechanical and current loads. First of all, the following malfunctions can be distinguished:

- Wear of electrical contacts, "pyatakov", as they are called by experts. Most often, they "burn out" under the influence of high currents.

- Open or short circuit of the relay winding.

- Faulty return spring.

- Damage to moving parts.

If any of the listed faults start the engine will be difficult or impossible. True, some of them can be fixed without significant costs. For example, on VAZ cars, the starter solenoid relay is collapsible, and therefore repairable.

Signs of malfunction

A traction relay is that rare case when you can almost reliably determine the cause of a malfunction by symptoms. The main ones are:

- lack of starter response to key turn;

- starter solenoid clicks but no crankshaft rotation;

- starter anchorspinning "idle";

- bendix does not return to neutral after starting the engine.

Despite the fact that in most cases the cause of the malfunction is obvious, it is desirable to make sure of this.

Checking the retractor

Diagnosis of the element is quite effective and does not require scarce tools and complex measuring instruments. Moreover, it will not take much time, since you can check the starter solenoid without dismantling it. Consider the main verification methods:

- When you turn the key, you can not hear the characteristic click of the retractor. In this case, in addition to the traction relay, the ignition switch and electrical wiring may be faulty. This can be precisely set using a test lamp. With one contact it must be connected to the "mass" of the car, with the other - to the retracting winding (flat contact on the relay cover). Move the ignition key to the "starter" position. If the lamp is on, the problem is in the traction relay. Otherwise, you need to look for other reasons. If you have a multimeter, you can check the relay by measuring the voltage. To do this, you need to connect its probes instead of a control lamp.

- Often when you try to start the car, clicks of the retractor are heard, but the starter does not turn. There can also be several reasons, ranging from a dead battery to relay contacts. It is easy to verify this. It is enough to close the contacts of the starter circuit (two large terminals on the cover of the retractor). Specialists do this right on the car, but in the absence of skills, it is better to remove the starter, it is more convenient, and most importantly, safer. If atwhen the contacts are closed with a conductor of the appropriate section, the starter starts to work, which means that the “pyataks” are burnt, disassembly or replacement of the retractor will be required.

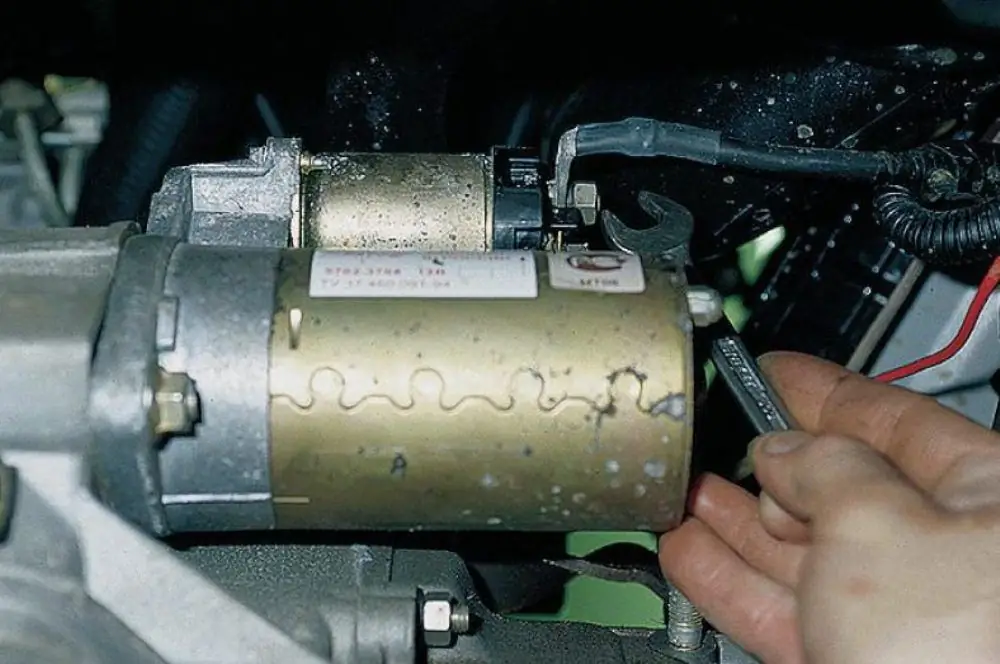

Relay removal

After the malfunction is localized and the failure of the retractor is reliably established, you can proceed to its dismantling. It is produced in the following sequence:

- Remove battery terminals.

- Dismantle the starter.

- Using a 13 key, unscrew the nut of the wire terminal of the brush assembly.

- Unscrew the 2 bolts, disconnect the retractor from the starter. In this case, you need to make sure that the core remains inside.

Now you can start repairing the starter solenoid relay. True, this is possible only if it is collapsible.

Relay repair

The complexity of this process greatly depends on the car model and the nature of the damage. In this case, the restoration of the operability of the contacts will be considered using the example of a starter solenoid relay 2109. The repair sequence is as follows:

- Remove relay from starter.

- Unscrew the two bolts on its back cover.

- Unsolder both contacts on the cover.

- Remove it, access to contacts opens.

- Take them out by unscrewing the two nuts by 13.

- Contacts are well cleaned of soot. If necessary, correct deformation caused by overheating.

- Assembly in reverse order.

It is worth noting that the above example is oneone of the few cases when it is worth repairing the retractor. The fact is that it is quite difficult to find spare parts for it. Therefore, in most cases, the problem is solved by replacing the starter solenoid relay with a new one.

Conclusion

Now on sale there are so-called gear starters. They are not installed at the factory, but there is no guarantee that the previous owner of the car did not do this. The solenoid relays on them are not interchangeable. Therefore, before buying a new one, you must first clarify which starter is on the car.

Recommended:

Where is the VAZ-2112 starter relay located? Location, purpose, replacement and device

The starter relay on the VAZ-2112 performs an important function on any car, regardless of model. Failure of this device leads to the fact that the car will not start. Drivers who are engaged in self-repair of the vehicle need to know where this unit is located and how to fix it if any malfunction occurs

Flashing "check" and troit engine: diagnostics, search for causes and repair

The car is a complex of complex components and mechanisms. No matter how automakers improve production technology and increase reliability, no one is immune from sudden breakdowns. This applies to all car enthusiasts. Both the owner of an expensive foreign car and a supported VAZ may encounter such a malfunction as engine tripping. Well, let's consider why the "check" is flashing on the car and the engine is troit

What to do if the starter clicks or does not turn in the VAZ-2107? Repair and replacement of the starter on the VAZ-2107

VAZ-2107, or the classic "Lada", "seven" - the car is quite old, but reliable. More than one generation of drivers "grew up" behind the wheel of this car. Like any type of transport, VAZ tends to break down from time to time. Quite often, breakdowns relate to the ignition system, in particular, such a part as a starter

VAZ-2114, starter relay: device, diagram and principle of operation

Information on how to replace the starter relay with a VAZ-2114. The design of the device, its malfunctions are described. The procedure for replacing the solenoid relay is given

Main starter malfunctions and how to fix them. Starter repair

Starter is an important element of any internal combustion engine. It is he who rotates after turning the key in the ignition, after which the engine starts. The starter creates the necessary revolutions for the crankshaft so that a compression ratio is formed in the cylinders sufficient to ignite the combustible mixture. If this mechanism is faulty, then starting a modern car will no longer work with the key. Let's learn about starter malfunctions, diagnostic methods and troubleshooting methods