2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

The high pressure fuel pump (TNVD) is one of the most important components of any diesel engine. It is with the help of this part that the fuel is supplied in such a way that not a liquid, but a fuel-air mixture enters the chamber. The operation of the injection pump is significantly affected by the plunger pair. Thanks to this element, the distribution and supply of fuel to the engine is carried out. And today we will look at what a plunger pair is, what significance it has for a diesel car.

Device

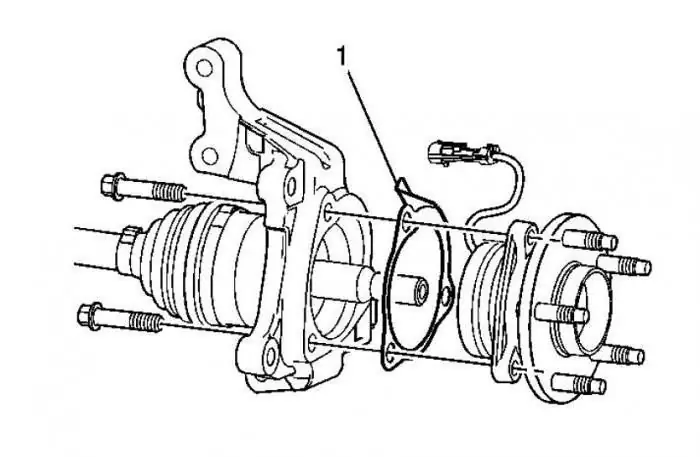

The design of this element assumes the presence of two main elements - a bushing and a plunger. The latter consists of a small cylindrical piston. When the pump is running, this part moves inside the sleeve. Thanks to the reciprocating movements that they produce, the fuel is injected, after which the fuel is sucked in. Plunger pair of injection pump (photothis element you can see below) has holes on the sleeve. Diesel fuel is supplied through them for injection.

That is, the main purpose and function of this element is to measure the exact amount of fuel for its supply to the engine cylinders. In addition, with the help of this element, the pump supplies fuel at a certain pressure at the right time. But in order to carry out all these operations without failure, the plunger pair must meet a number of technical requirements. Its very production is carried out on high-tech equipment (as a rule, at large enterprises). It is impossible to make such an element at home.

About delivery valves as an integral part of the fuel system

The main task of this element is to block the high pressure lines between the plunger and the fuel line. Due to this, a decrease in fuel pressure occurs, which is necessary for more accurate and faster closing of the injector nozzles. This prevents the formation of fuel droplets, and their presence there is highly undesirable. During injection, the pressure that is created in the space above the plunger causes the cone of the discharge valve to rise. Further, fuel under pressure enters the atomizer through the fuel line and valve holder. As soon as the plunger groove opens the drain channel, the pressure level in the chamber drops, and the discharge valve spring presses the device body back against the seat. Such an actionoccurs in the system until the plunger starts a new stroke.

Is the plunger likely to leak?

In quality parts, the probability of fuel leakage is zero. To minimize the likelihood of fuel leakage, the gap between the sleeve and the plunger is made equal to 1-3 microns. Due to this high accuracy, each plunger is matched separately to the sleeve. After that, both parts are adjusted at the factory. During manufacture, the surface of these elements is additionally hardened. This is done in order to ensure the longest possible life of this part.

Part operation

The plunger pair is the element that requires special attention during the operation of the vehicle and the operation of its fuel system. The key to high-quality and uninterrupted operation of this part is the use of only high-quality fuel. Unfortunately, at domestic gas stations, few monitor the quality of fuel, so our car owners (especially those who have diesel cars) often have to repair and clean nozzles.

The content of various chemical impurities and a high concentration of dirt and deposits significantly reduce the service life of plunger pairs. Water, which is also sometimes found in domestic fuel, has a particularly negative effect. When it enters the gap between the sleeve and the plunger, the integrity of the lubricating film is broken, as a result of which the device starts to work without lubrication. This can lead to increased heat, deformation and even jamming.such a detail as a plunger pair. In this case, there is only one way out of the situation - replacing the device with a new one. In order to avoid such troubles, you need to regularly diagnose fuel equipment and, if possible, do not refuel at unfamiliar gas stations.

When do you need to replace the plunger pair?

There are several main symptoms that indicate a malfunction of this part. One of them is the failure to start the engine. But it is possible to determine the breakdown of the plunger pair even with the engine running. In this case, you need to pay attention to the quality of the motor. If it is unstable and intermittent, most likely the reason is hidden in the fuel system. Also, with a faulty plunger pair, the motor begins to significantly lose its power and make extraneous sounds that have not previously occurred. If you notice at least one of the above symptoms, you need to diagnose the vehicle's fuel system.

It is worth noting that for this you need to have special diagnostic equipment. Therefore, with your own hands and without the appropriate equipment, you are unlikely to be able to determine the he alth of the plunger. After the diagnosis, the masters decide whether the plunger pair needs to be adjusted or whether it should be completely replaced with a new one. During the repair, certain equipment is used that restores the factory sealed dimensions of the plunger and sleeve. The replacement itself also requires special care, knowledge and experience, so doing something in a high-pressure fuel pump with your own hands is extremelydangerous as it could damage the entire system in the car.

Conclusion

So, we found out how plunger pairs affect high-pressure fuel pumps and all their design features.

In general, the diesel engine fuel system is a very complex mechanism that requires special attention and extremely high-quality fuel. In this regard, the number of diesel cars in our country is an order of magnitude lower than in Western Europe. After all, it is almost impossible to service the fuel station with your own hands, and hardly anyone wants to spend money regularly on expensive repairs and diagnostics.

Recommended:

Band brake: device, principle of operation, adjustment and repair

The brake system is designed to stop various mechanisms or vehicles. Another purpose is to prevent movement when the instrument or machine is at rest. There are several varieties of these devices, among which the band brake is one of the most successful

Starter VAZ-2105: problems and solutions, replacement and repair rules, expert advice

VAZ-2105 is still popular with Russian drivers. It is distinguished by ease of operation and low cost of spare parts. However, if the car owner wants the car to work without problems, he must regularly check it for various faults

KAMAZ 740 crankshaft: device and dimensions, repair, replacement

Crankshaft "KAMAZ 740": device, features, photos, operation, dimensions, maintenance. Crankshaft "KAMAZ 740": characteristics, repair, replacement, bearings. Comparative characteristics of the crankshaft "KAMAZ 740" and its analogues

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

UAZ clutch slave cylinder: adjustment and replacement

A clutch is provided in the device of any car. This system produces a smooth engagement and disengagement of gears, transferring torque from the flywheel to the wheels. This is controlled by the master and slave cylinder of the clutch. UAZ "Loaf" is also equipped with it. In today's article, we will look at what a working element is, how to replace and adjust it