2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Most motorists are wary of turbochargers. And there are reasons for this. The repair of these units is quite expensive, despite the availability of repair kits for them on the market. Replacing a turbine is also an expensive pleasure. But in case of replacement, a new trouble-free unit is installed.

Diagnosis

Turbines work at the crossroads of several engine nodes, and the he alth of a turbocharger is highly dependent on the he alth of these nodes. Therefore, if there are any complaints about the operation of the turbine, the first thing you need is competent diagnostics. It will be a guarantee that after replacing the turbine or repairing it, the compressor will not die after several thousand kilometers.

First, with the help of computer systems, the computer as a whole and the sensors are checked. Most turbochargers are equipped with a boost pressure control mechanism. The failure of this mechanism may be due to some banal error or malfunction - incorrect data from the flow meter. It is not uncommon for cases when, due to ignoring diagnostics in a software company,To repair compressors, car owners bring or bring completely working units, and some only need to replace the turbine cartridge.

Leakproof

The he alth of a turbocharger is highly dependent on whether the intake and exhaust of the power unit are tight, and what pressure is in the intake and exhaust. If, for example, the catalytic converter and air filter are clogged, the intake vacuum will be high and the exhaust backpressure will be increased. This significantly affects the resource of turbocharger parts - bearings are especially affected, as well as the seal and shaft. If the pressure drops are large, then the turbine, due to design features, will drive oil more into the intake system, as a result of which the intake pipes and pipelines will be covered with a greasy coating.

Foreign objects in the impeller

This is another reason why compressors can fail. Sometimes this can happen due to the carelessness of mechanics who left rags in the intake tract during repair work, or if a washer fell inside. Often, foreign objects enter the turbine due to the unforeseen destruction of individual engine parts. The turbine shaft rotates at very high speeds, and if even a spark plug electrode gets into the impeller, the impeller may at least be deformed, or the part may jam. The rotor will just break in half. In this case, there is no point in repairing, and only a complete replacement of the turbine will help.

Over RPM

This is another typical reason whyimpeller and shaft. And over-revving can be caused by more than just chip tuning. RPMs can also increase on their own due to incorrect air flow sensors.

Basic rules for replacing a turbocharger

Repair specialists claim that among the majority of causes of turbine failures, it is external factors that can be highlighted. Therefore, before installing a new unit to replace a broken one, it is worth diagnosing and finding out the reason why the previous one failed.

Then you should make sure that the replacement unit is selected correctly. You need to carefully examine the old turbocharger and the new one. Check for conformity of external design features, check identification numbers.

Cleanliness is important during turbine replacement - even a small amount of dirt can cause compressor failure.

Replacement instructions

The first step is to clean the air ducts, as well as the intercooler in the intake tract from oil, dirt, deposits, and other foreign objects. Then these elements need to be inspected for damage and various obstacles. It is recommended to verify that the exhaust gas recirculation valve and air damper, if equipped, are working.

Then you need to replace the air filter. This procedure may be different for each vehicle. After this, the exhaust system must be thoroughly cleaned and also ensure that any damage and obstruction to the free exit of gasesmissing. If oil enters the exhaust tract when the turbocharger fails, then check the condition of the catalyst and the particulate filter. If necessary, before replacing the diesel turbine, these elements are cleaned of various deposits and soot. If it is not possible to restore the capacity of the catalyst or particulate filter, then they are either changed to new ones or removed.

Then, experts recommend checking the cleanliness of the oil supply and drain systems. If necessary, remove hydrocarbon deposits, coking and other obstacles. If there is even the slightest doubt about the cleanliness of the systems, it is better to replace the parts.

After that, the he alth of the lubrication system of the engine itself is checked. If there is a suspicion of inefficiency of the systems, then the operation of the oil pump and pressure reducing valve is checked.

When replacing a turbine on a Mazda and other car brands, the oil in the engine is changed, and with it the oil filter. You need to make sure that the oil is suitable for the car.

Check the serviceability of vacuum systems, if any. The vacuum pump must be cleaned of deposits and dirt, check whether the tubes and the places where they connect are tight.

Then check the condition of the exhaust manifold - it should not have cracks either inside or outside. The flange must have a flat surface, without cracks and defects, without carbon deposits. Studs must not be damaged.

The turbine is fixed on the flange on the outletcollector. It is important to make sure that the gasket is properly installed and will be able to provide a good seal.

When replacing a turbine on a Ford and other brands, connect an oil drain pipe through the original gasket. Experts categorically do not recommend using so-called gasket sealants as sealants.

Then, through a special oil supply hole, the unit is filled with clean engine oil. It is important to turn the impeller by hand when pouring oil. It is strictly forbidden to turn the rotor without lubrication.

What should be done after replacement? Tips from the masters

All fittings are then connected to the compressor. If possible, after replacing the turbine, it is necessary to exclude the possibility of starting the engine. The engine should be rotated by the starter until the oil pressure light goes out. Only after that the engine is started and allowed to run for several minutes. During the operation of the engine, it is important to make sure that each connection is tight, there are no air leaks, no oil flows, no exhaust gases escape. All seals are threaded per manufacturer's recommendation.

Then you can test on the road, once again check all systems for leaks. It is also recommended to perform an electronic diagnosis of the motor.

Recommended:

Electro-turbine: characteristics, principle of operation, pros and cons of work, do-it-yourself installation tips and owner reviews

Electric turbines represent the next stage in the development of turbochargers. Despite significant advantages over mechanical options, they are currently not widely used on production cars due to the high cost and complexity of the design

Reversing lamp: tips for choosing, possible problems, replacement procedure, reviews

Safe driving in the daytime and in the dark is ensured by the operation of the car's optics. Its most important component is the reversing lamps. Why they can fail, how to return them to working condition, read the article

Clutch master cylinder. "Gazelle": device and repair of the clutch master cylinder

To set the car in motion, it is necessary to transmit torque from the engine to the gearbox. Clutch is responsible for this

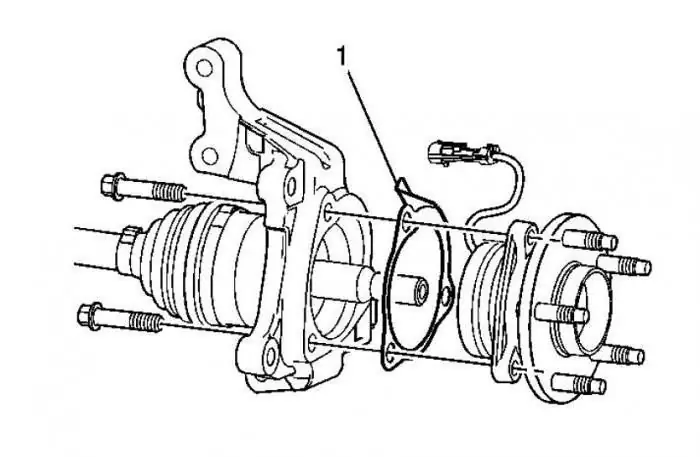

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Turbine installation: description, features, diagram and reviews

Which of the car owners did not dream of increasing the power of their car? Everyone thought about it. Some would like to add 10 horsepower, others - 20. But there are those motorists who want to increase the capabilities of the car as much as possible. Their goal is the maximum increase in torque with a minimum budget, which means that a powerful engine from another car can no longer be installed. This means that there are only two options left to increase the technical characteristics - a compressor or turbine installation