2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Almost all motorists have heard of such a service as carbon wrapping, but how many have wondered what it is?

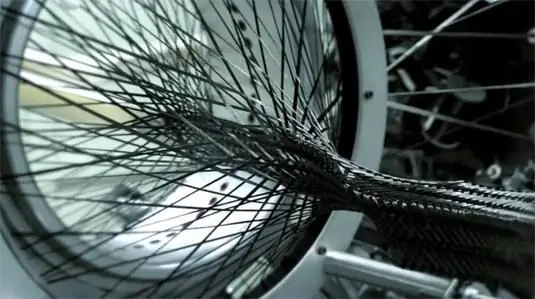

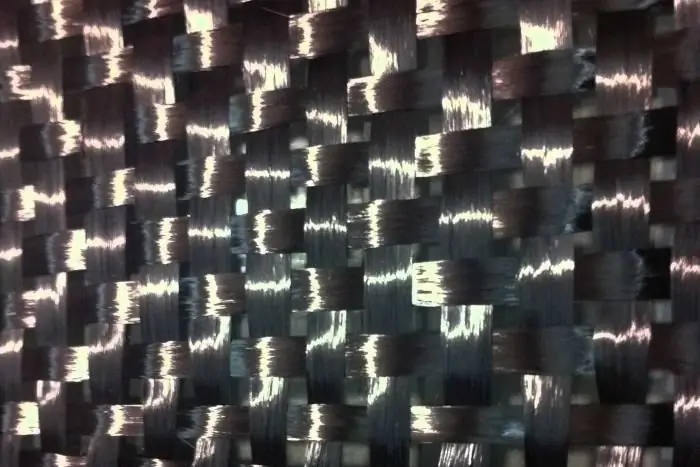

Carbon is carbon fiber reinforced plastic, consisting of carbon filaments bonded with epoxy resins. These threads are woven into a fabric with a different weaving pattern. To strengthen the material, fabrics are interconnected in layers using epoxy resins, while changing the direction of the pattern.

For the first time, carbon was used in the construction of spaceships. Now it is widely used for wrapping car body and interior parts.

Carbon wrapping has its positive aspects. This material is particularly strong and light in weight. It is 20% lighter than aluminum and half lighter than steel. In terms of strength, carbon is not inferior to fiberglass and many metals, which is why it is so loved by the designers of racing cars. After all, the combination of strength and lightness of parts is a very important factor for success in motorsport, so carbon wrapping is relevant for racing car cockpits.

The main and, perhaps, the only drawback of carbon fiber is its high cost. Toto manufacture this material, expensive components and the use of complex technologies are required. High-quality resins are used to bond the layers together, and the use of expensive equipment is also required. Hence the rather high cost of the material.

Carbon suffers greatly from point impacts and from sunlight. After six months of driving, due to the constant ingress of fine gravel, the carbon hood will turn into a sieve. And under the influence of the sun, the material fades, and after a while its color will be much dimmer than the original shade.

While fiberglass or metal parts can be refurbished, carbon fiber cannot. Therefore, if the part is damaged, carbon fiber is re-wrapped. The price of such procedures is very high, which is why carbon is not available to everyone.

But there was a way out of this situation. Since our car enthusiasts liked carbon more because of its presentable appearance, a relatively inexpensive service has become widespread - wrapping with a carbon-look film. For this, PVC (polyvinylchloride) films with a variety of carbon weave patterns are used. Such a film can be pasted over all the elements of the body and interior of any car.

Using a film replaces a full-fledged painting, while saving money. It will also serve as a good protection of the paintwork from scratches, chips, damage during the operation of the car. And if suddenly the colors get boredcar owner, it will not be difficult to make the car glossy, matte or apply a unique pattern to it. The film can be easily removed without damaging the original coating.

If there is a choice: wrapping in carbon or film, it is better to lean towards the second option. The film coating will give the car an individual stylish look and will not constrain its owner in funds.

Recommended:

How to clean pistons from carbon deposits? Methods and means of cleaning pistons from carbon deposits

In order for the car engine to work properly for a long time, you need to monitor its condition, periodically cleaning the elements from carbon deposits and dirt. The hardest part to clean is the piston. After all, excessive mechanical stress can damage these parts

Carbon film, its structure and application

The article will tell about the qualities of the carbon film, its application. You will learn about the positive and negative characteristics of this material, as well as what this product can replace

Car wrapping with carbon film

Wrapping a car with a carbon film is quite popular today. Therefore, in this article I will tell you how it happens

Carbon pasting: necessary materials and tools, pasting technology

Pasting car parts with carbon fiber is becoming increasingly popular both in the world and in Russia. And this is not surprising, since the film protects the surface from chips and cracks, and also gives the car a great appearance