2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:17

Oil compressors are one of the most popular types of mini piston stations. Their popularity is due not to high performance and wide functionality, but to the balance of various operational parameters. In particular, the combination of modern ergonomics and versatility in terms of connection to various equipment makes the piston oil compressor in demand among automotive craftsmen. Such installations are also used in households - an affordable price and small dimensions make such purchases the most profitable.

Purpose of the unit

The main function of reciprocating compressors is to supply compressed air at certain pressure and power levels. The most widespread use of such devices is in workshops where painting work is required. To implement such measures, a piston oil compressor is connected to a special apparatus that provides spraying of the paint and varnish composition. In small car services, for example, a combination with spray guns is used, and in large industries, the compressor can also work together with professional units that work with abrasive substances.

Another common operation for which such equipment is used is air inflation. Again, depending on the application, this can be a bicycle tire or an inflatable boat. In accordance with the requirements for air volume and supply force, an oil compressor in one modification or another is also selected. Less common are procedures related to the process purge of locks, engines and various mechanisms.

Design and principle of operation

Oil compressors can have one or two cylinders, in which the main functional operations take place, providing the supply of the working mixture. Two-cylinder models are considered more productive, since they assume the simultaneous operation of two piston mechanisms. At the same time, an oil compressor in this design requires more attention in maintenance. Such activities are associated with the replacement of filters and the cleaning of cylinders from oil impurities. Compressed air accumulates in the receiver, during which condensate is released. Excess formed moisture must be removed manually or automatically by means of a special system. The complete elimination of condensate, for example, is possible with the use of special dryers. Manufacturers also provide pressure regulators and pressure gauges on compressor housings of this type.

Performance

Largely due to balanced technical parameters, this type of compressor has receivedwide use. Not the main, but the basic operating parameter that can affect other characteristics is power. It varies for oil models on average from 1500 to 2200 watts. Power is reinforced by pressure - for small household operations, 6 Bar is enough, but tasks of medium complexity require a capacity of 8-10 Bar. Also, the oil compressor is equipped with a receiver, the capacity of which can be 25-200 liters. Together, these parameters determine the most important characteristic in terms of practical use - performance. This indicator varies from 200 to 400 l / min. However, professional models provide more than 500 l/min.

Varieties

In this category, there are several types of compressors, among which belt and coaxial models deserve attention. They can only be classified as traditional oil-type models, but they are quite serious competition. So, if you need to work with a pneumatic tool, then an oil coaxial compressor will be the best option. The advantages of such units include modest dimensions, the possibility of automatic lubrication and additional equipment with auxiliary equipment.

Ordinary users often have a choice between low-power household and expensive professional models. The former are convenient, but do not always meet operational requirements, while the latter provide ultra-high performance, but are inconvenient to use.content. As an intermediate option, it is worth considering an oil belt compressor, which is distinguished by its durability, small size and sufficient power for medium needs. True, the belt drive increases the noise of the unit and the vibration effect.

Manufacturer Reviews

Users highly appreciate the performance of well-known brands of compressors, including Fubag, Metabo, Patriot, etc. As practice shows, their reliable assembly withstands the toughest working conditions, and ergonomic devices facilitate the operator's function. The middle niche features lesser-known firms such as Kaeser, Remeza and Fiac. In the families of these companies, you can find an affordable oil compressor, which also does not disappoint in the process of use. According to the performance and reliability criteria, users also respond quite well to domestic products. For example, high-quality compressors are produced under the Energomash, Prorab and Kalibr brands.

Conclusion

The process of operation of compressor stations in most cases also involves auxiliary accessories. This group of devices includes adapters, couplings, hoses for supplying working media and other accessories. Typically, an air oil compressor is supplied with sets of such devices, but non-standard fittings may also be required to perform highly specialized tasks. In addition, work with pneumatic tools is strictly regulated by safety requirements. It concernsand painting operations, and especially abrasive spraying processes, during which the use of goggles and gloves is mandatory.

Recommended:

Changing the oil in a Mercedes. Types of oil, why it needs to be changed and the main task of engine oil

A car is a modern vehicle that needs to be monitored every day. A Mercedes car is no exception. Such a machine should always be in order. Changing the oil in a Mercedes is an important procedure for a vehicle. In this article we will talk about how important it is to carry out this procedure, what types and types of oil are

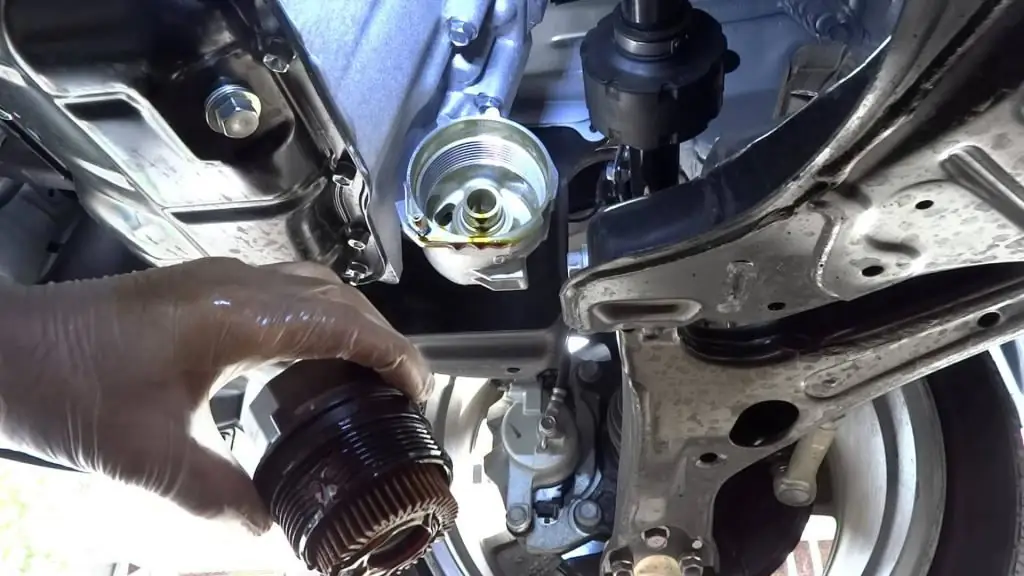

Oil change in Toyota: types and choice of oil, specifications, dosage, do-it-yourself oil change instructions

The reliability of your car depends on quality maintenance. To avoid additional repair costs, it is recommended to use engine oil in a timely and correct manner. The operation of any car implies a number of regulatory requirements. Toyota oil change must be carried out according to the instruction manual. It is recommended to perform the procedure after every 10,000-15,000 km of the vehicle run

Oil change VAZ 2107: types of oil, specifications, dosage, instructions for changing the oil yourself

The article contains detailed instructions for changing the oil in VAZ 2107 engines. In the text you can find information about when a change is required, what kind of oil happens, the tools necessary for the "procedure" and a complete description of the process of changing the oil in a car

Changing the oil in the Chevrolet Niva engine: the choice of oil, the frequency and timing of oil changes, tips from car owners

The car's powertrain needs regular maintenance. The engine is the heart of any car, and its service life depends on how carefully the driver treats it. In this article we will talk about how to change the oil in a Chevrolet Niva engine. Despite the fact that every motorist can do this, there are some nuances that you must first familiarize yourself with

A piston is a part of a car engine. Device, replacement, piston installation

The piston is one of the elements of the crank mechanism, on which the principle of operation of most internal combustion engines is based. Such parts have three components. Their features are determined primarily by the material and method of production