2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:09

According to the reviews of the owners and specialized sources, repair of the Chevrolet Niva engine may already be required after 60 thousand kilometers. It all depends on the intensity of use of the vehicle and driving style. Also, this indicator is affected by the type of motor and the quality of its assembly. Often, a car is able to go over 100 thousand kilometers without interfering with the power unit.

Preparation

In order to repair the Chevrolet Niva engine, you will need to stock up on the necessary set of tools. This set includes:

- a set of keys from "10" to "36" or a universal analogue, you can also use a gas model;

- sockets for "12" and "13";

- hammer;

- screwdriver;

- special oil filter puller.

If possible, it is better to work on a turntable, which allows you to get close to the motor from different sides. This feature is due to the fact that the power unit is quitedifficult to fix securely. Otherwise, fasteners that are overtightened are difficult to unscrew.

Beginning of disassembly

This Chevrolet Niva engine repair procedure begins after disconnecting all connecting hoses, pipelines and clamps. Work is performed in the following sequence:

- remove the oil filter according to the recommendations of the work instructions in the relevant section;

- dismantle the clutch mechanism;

- remove the flywheel;

- remove the cylinder head;

- unscrew the three fixing bolts of the refrigerant pump housing, and then remove the pump assembly with a pulley;

- release the tightening force of the insufficient oil pressure indicator, while keeping the adapter from scrolling;

- remove the camshaft timing chain tensioner shoe.

Main Stage

Further repair of the Chevrolet Niva engine (VAZ-2123) is also a few steps. They are listed below:

- Using a screwdriver, shift the crankshaft sprocket, followed by removal. Bend the edge of the stopper washer, unscrew the fastening bolt, dismantle the toothed element.

- Remove the camshaft drive chains.

- Dismantle the plug of the mounting socket in the hole of the cylinder block.

- Remove the crankcase breather cap.

- Unscrew a pair of screws securing the thrust flange on the oil pump drive, then shift the roller and removehim.

- Remove the two fixing nuts on the front of the crankcase.

- Unscrew the six fasteners of the BC holder, dismantle the oil seal by gently prying it with a screwdriver.

It is important at this stage not to lose the two square head bolts that move freely in the sockets of the holder cover, they can easily fall out.

Finishing stage of dismantling

Further repair of the Chevrolet Niva engine also consists of certain stages:

- Unscrew the remnants of the bolts on the oil sump, remove the washers and the container itself.

- Remove the remaining gasket, unscrew the two mounting bolts, dismantle the oil pump.

- A pair of nuts is installed on the fixing stud. By simultaneously tightening them, the hairpin is turned out.

- Remove the bolt fastener of the oil separator drain bracket, and then remove the bracket by moving it along the tube to the edge.

- Dismantle the section with the oil separator.

- The elements of the crank group are marked by location, which will allow working and serviceable mechanisms to be installed back.

- Twist the fixing nuts of the connecting rod of one of the cylinders.

- Remove the remaining plugs and crankshaft.

Knowing how to remove the engine cover and related components, you can begin to replace and repair parts.

Troubleshooting

This process begins with the preparation of tools. You will need the following tools:

- portable lamp;

- ruler or tape measure;

- caliper;

- scraper;

- flat probe set;

- micrometer.

Do-it-yourself engine overhaul will require thorough washing of parts in kerosene in the future. Then they must be blown and dried with compressed air. A careful visual inspection of the crankshaft bearings and other components is carried out for the absence of cracks and chips. In cylinders, similar defects are also not allowed.

According to the manufacturer's documentation, a stamp with a conditional index of the cylinder block is applied to the bottom of the block. A similar number must be present on all compartments of the main bearings, which determines their belonging to a specific cylinder head assembly.

Further manipulations

Chevrolet Niva engine repair in terms of troubleshooting includes the following steps:

- Check the difference between the surface of the block connector with the cylinder head. This is done with a caliper. If the deviation in the diagonal, transverse or longitudinal direction exceeds 0.1 mm, the unit must be replaced.

- Clean the bottom of carbon deposits with a scraper, which is often made from an old file.

- Also remove burn marks under the piston rings by turning it.

- Inspect pistons, connecting rods and caps for cracks.

- Visually check the liners. Elements with chips, cracks and scuffs are changed.

- Check the diameter of the pistons in a plane at a distance of 52.4 millimeters from the bottom of the part. The calculated value must be inwithin 0.05-0.07 mm. The maximum allowable gap is 0.15mm.

- The piston is turned with the finger axis up, while it should not fall out of its socket. Otherwise, the finger must be replaced.

- Check with a flat feeler gauge the distance between the piston grooves in height. Nominal clearances here range from 0.04 to 0.15mm.

Recommendations

A few more tips on how to refine the Chevrolet Niva engine. You will need to inspect the upper and lower main bearings. 1, 2, 4, 5th elements are equipped with special grooves on the inside. The lower analogues of such sockets do not have. If there are scuffs, chips and cracks on the indicated elements, they require replacement.

It is also recommended to pour gasoline into the radial passages. Before that, they must be drowned out on one side with wooden chops. After a 15-20-minute exposure, the channels are washed with fuel, which is fed through a rubber bulb. The plugs are dismantled, the channels are washed until clean gasoline flows out.

Flushing and decarbonizing with Dimexide

This method is quite simple and not very expensive. To perform the procedure, do the following:

- purchase inexpensive mineral oil, such as Volga OIL 15 (10 liters);

- buy a flushing agent like Lukoil (4 l);

- replace the original filter element;

- four pieces of DODA oil filters (better quality analogues);

- you will also need a PTFE tube8 mm in diameter, about 0.4 m long;

- M6 hairpin;

- thermal shrinkage.

For decoking with Dimexide, you will need the solution itself (about 2.5 liters), as well as a syringe, an industrial hair dryer, a drill, gloves and rags. It is worth noting that this procedure requires compliance with certain safety measures associated with the use of PPE. The composition in question leaves burns on the skin, not to mention the mucous membranes. In addition, it has a negative effect when it comes into contact with most types of plastic. On average, with a careful and unhurried independent approach, the entire operation will take from 6 to 8 hours.

How to flush the Chevrolet Niva engine correctly?

Step-by-step instructions for performing this process are given below:

- The probe is removed by processing the element with Dimexide. To do this, you need to unscrew the fixing bolt E12, pull the probe up. Doing so may spill a small amount of oil.

- Then turn the probe over without pulling out the cable, pour the indicated composition into the container, and then heat the tube with an industrial hair dryer. The paint will begin to peel off in layers in just a matter of minutes.

- The probe is turned over again, the paint is removed from it in the usual way, the element is washed with water. It is necessary to check that there are no paint residues left inside the measure, after which it is placed on the seat.

- The Chevrolet Niva engine (VAZ-2123) is being warmed up, driven intohill.

Final operation

Flushing continues by preparing a special tool. It can be made from an M6 stud, which is rounded and polished at one end. Since the internal dimension of the PTFE tube is larger than the corresponding diameter of the stud, heat shrink will be required to tightly position the two mating elements.

Regardless of what oil is in the Chevrolet Niva engine, the following sequence is observed:

- Cut the end of the tube by 20 millimeters and bend it like a propeller.

- The so-called mixer should preferably be made of PTFE. This is due to the fact that the specified material is resistant to various kinds of acids, alkalis and oxidizing agents. It is important to remember here that Dimexide is a rather aggressive substance that can simply corrode ordinary plastic and ruin high-quality plastic. At the same time, it will be very problematic to get decay products.

- Next, you have to "dive" under the car, remove the motor protection and boot. Thus, it will be possible to get to the fixing bolt of the crankshaft.

- Unscrew the candles and insert metal pins of suitable size into the vacant holes.

- The mechanism is rotated clockwise with the crankshaft bolt until the installed "skewers" are in a row.

- Using a building hair dryer, heat "Dimexide" in a suitable container, pour 100 milliliters into tubes.

Flushing: final step

While it goesthe process of heating the processing composition, it is possible to simultaneously dose the composition with a syringe to the intended places. This is due to the fact that the efficiency of "Dimexide" drops rapidly when the power unit cools down. A mixer with a drill is turned on at a power of about 2500 rpm, after which each cylinder is processed in 2-3 passes. As a result, each element takes at least five minutes.

After that, Janet's modification syringe is pumped out using a dropper with a tube, all the filled composition is poured back into the containers. This will make it possible to understand how much Dimexide was spent on processing the rings and the oil system. Next, the second and third portion of the composition is heated alternately, after which the procedure is repeated in a similar way.

Result

How long the Chevrolet Niva engine runs without repair was indicated above, depending on the condition of the car, its correct maintenance and road conditions. In any case, problems with the motor should not be ignored. Timely flushing and cleaning will save money and the resource of mating vehicle parts.

Recommended:

Which engine oil is better for Niva-Chevrolet: review of oils, recommendations, experience of motorists

The Chevrolet Niva compact crossover SUV is very popular in our country today. This is due to the successful design of the car for our roads, very affordable pricing for components and spare parts for the car, as well as the price of the car itself. Of course, if the car is popular, then questions about its service are also relevant. It is for this reason that today we will talk about which engine oil is best for the Chevrolet Niva? Let's start looking into the issue

Engine overhaul: frequency, stages and features of work

Overhaul of the engine is a process during which the engine and the main units of the power system are brought to the factory state. The overhaul of the power unit is an expensive and time-consuming work that requires special skills and the installation of high-quality spare parts. Timely diagnostics, maintenance and repair can extend the life of the engine

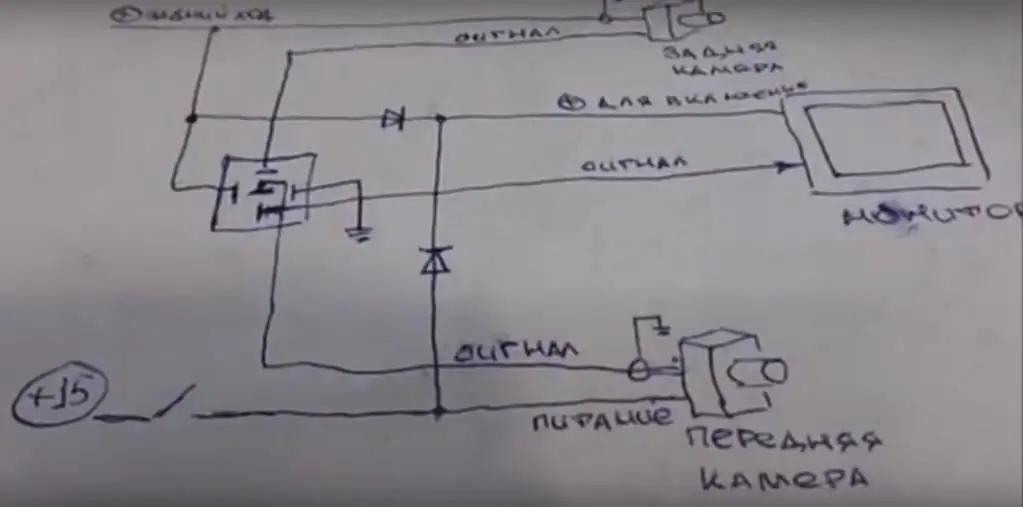

Rear view camera connection diagram: diagrams, work order, recommendations

The number of cars on the roads is growing exponentially. There are fewer and fewer parking spaces. At the same time, manufacturers are increasing the dimensions of passenger cars, thereby reducing their ability to maneuver in the parking lot. This leads to emergency situations when reversing. Installing a rear view camera on the car will help solve this problem

GAZelle body repair - methods and recommendations

An integral feature of any truck is the presence of a body. There may be several options for its implementation. This is an awning, a van, a refrigerator, a furniture booth and so on. But since loads are constantly transported in the body, the power structure wears out and loses its strength. In today's article, we will talk about how to repair the GAZelle body with our own hands

Car "Gazelle" rear axle: diagram, replacement, repair and recommendations

On the domestic Gazelle car, the rear axle is equipped with a separately modeled gearbox and a stamped-welded crankcase. The last element has a box section, welded from shell-shaped steel plates