2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

On the domestic Gazelle car, the rear axle is equipped with a separately modeled gearbox and a stamped-welded crankcase. The last element has a box section, welded from shell-shaped steel plates. Attached to them is a rear cover, an amplifier for fastening a gearbox, spring pads, shock-absorbing and fixing brackets for a rack, a brake regulator, a trunnion with flanges. It is used for mounting hubs and brake elements. The main gear of the axle and its differential are installed in the gearbox housing, bolted to the frame of the node in question.

Maintenance

In order for the rear axle to serve reliably and for a long time on the Gazelle car, it is recommended to follow several rules for its maintenance. The main ones are as follows.

It is necessary to control the absence of oil leakage on the cuffs of the drive gear and wheel hub, as well as through the gasket of the gearbox housing and axle shaft flanges, filler and drain caps. It should be noted that the appearance of condensate in these places does not indicate a leak, unless there are signsfalling drops.

It is necessary to check the oil level in the bridge crankcase, top up the working fluid if necessary.

Oil change should be carried out according to a special map for the use of lubricants.

It is required to check the degree of tightening of the bolts for fixing the gearbox, axle shafts and adjust the wheel hub bearings.

Below is a diagram of the node in question.

Main signs of malfunction

Pay attention to the operation of the rear axle should be in the presence of at least one of the signs below:

- Increased noise and hum in working condition.

- Incorrect operation of node with drops (pulsating noise).

- The appearance of high-pitched sounds (howling).

- Loud knocking in the area of the node in question when the accelerator is activated when cornering or when coasting.

- Constant non-standard sounds and crunch.

In addition, the rear axle of the Gazelle car needs repair if oil is leaking through the crankcase planes, cuffs or drain plugs.

Ways to fix defects

The following are the main problems and how to solve them.

The fixing bolts or nuts of the driven gear, crankcase are loose - it is necessary to tighten the fasteners.

Wear, the appearance of backlash in gear or differential bearings - you need to check the condition of the elements, if necessary, replace them or adjust the tightness.

Insufficient oil level or not usingrecommended fluid - top up or change oil with a suitable option.

There are scuffs, cracks, chips on bearings, gear teeth - replace defective parts.

Clogged breather - clean it.

Excessive wear of elements - the issue is resolved by installing new ones.

If the crankcase, gaskets or rear axle oil seal (Gazelle) are leaking, it is imperative to replace unusable parts.

How to start disassembly and replacement

To repair the assembly in question and replace defective parts, it is necessary to disassemble the rear axle, which is a rather difficult and painstaking task. The following step-by-step instructions describe the dismantling steps:

- The bolts (10 pcs.) fixing the gearbox are unscrewed with a special ring wrench.

- The gearbox is removed carefully so as not to damage the gasket (it is more convenient to work on the stand).

- The drive gear flange and cuff are removed, after which marks are made for the location of the covers relative to the bearing nuts and the crankcase itself.

- The flange is removed with the cuff, with the help of a wrench the bolts of the locking plates are unscrewed, which are removed.

- The fasteners of the bearing caps are unscrewed with a spanner or socket wrench, after which they are dismantled.

- Using a screwdriver or wrench, the adjusting nuts are removed, then the satellite box.

- In case of reinstallation of the same bearings, their outer rings are marked for mounting in the old places.

- To simplify assembly, marks are also placed on the satellite box, after which the gear mounting bolts are unscrewed.

Next steps

Disassembly and replacement of the rear axle ("Gazelle") continue on the following points:

- with light blows of the hammer on the knockout, the gear is knocked off and removed from the box;

- using a special tool or a chisel that is inserted between the end face of the inner bearing ring and the differential box, the ring is moved to the side and removed through the resulting gap with mounting blades (screwdrivers);

- marks are placed on the location of the differentials in relation to the satellite axles, fasteners are unscrewed;

- box is disassembled by tapping soft drift with a hammer;

- removing side gears and thrust washers;

- the drive gear is dismantled in a manner similar to opening the box;

- adjusting and outer rings of bearings are removed.

Tail of the rear axle ("Gazelle") and other elements should not have cracks, chips and deformations. All worn parts must be replaced. Before assembly, the parts must be lubricated and the assembly procedure carried out in a mirror order.

Recommendations

After a hundred thousand kilometers, experts recommend replacing the bearings in the assembly in question, regardless of their condition. If there are signs of a malfunction, and the repair of the rear axle ("Gazelle") is delayed, in order to avoid a more serious breakdown, severalrules.

First, do not overload the car, especially in the summer. Secondly, to minimize the use of first gear, driving in which has a particularly negative effect on the gearbox. In addition, abrupt starts, steep and long climbs must be avoided.

At the Gazelle car, the rear axle will last longer if you buy and use only high-quality and recommended oil, replace it at least every 35-40 thousand kilometers. Timely elimination of backlash, avoidance of slipping in snow or mud also help to increase the service life of this unit.

Recommended:

Rear axle of a car - device and purpose

The rear axle is a mechanism that serves to transfer forces to the wheels and their subsequent movement. The power transmission path starts with the engine. Then the power goes to the gearbox, then to the driveshaft, final drive, differential and axle shafts. Only then do the traction forces drive the wheels. It should be noted that in this case we are considering a leading rear axle

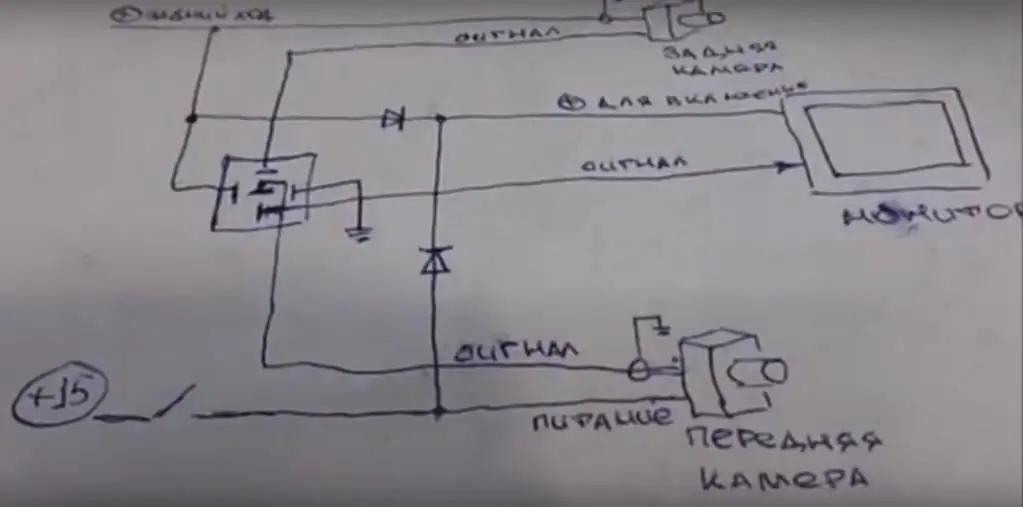

Rear view camera connection diagram: diagrams, work order, recommendations

The number of cars on the roads is growing exponentially. There are fewer and fewer parking spaces. At the same time, manufacturers are increasing the dimensions of passenger cars, thereby reducing their ability to maneuver in the parking lot. This leads to emergency situations when reversing. Installing a rear view camera on the car will help solve this problem

Front axle MTZ-82: diagram, device and repair (photo)

The front axle of the MTZ-82 tractor is a complex mechanism. It has many details that interact with each other

Rear brake disc replacement and repair

Brake discs are the most important part in the system of any car. The condition of this part depends on the safety of the driver, passengers and other road users. If one of the discs is worn out, this is a direct safety hazard on the road. Often the front discs experience higher loads, but this does not mean that the rear brake disc is not a critical part. This element requires maintenance, replacement and repair in the same way as the front

How to independently repair the GAZelle rear axle gearbox

Repair and replacement of the rear axle gearbox (GAZelle 33021) is a very serious and responsible business. As you know, this spare part has a very complex design, so any repairs with it should only be made at a special service station using special tools and equipment. However, if you are an experienced driver and know the design of the GAZelle like the back of your hand, self-repair will not be ineffective