2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-06-01 05:35:55

Since ancient times, people have been engaged in earthworks. Modern volumes of such procedures are simply colossal (construction sites, quarries, roads). Manually doing all the processes is simply unrealistic and too long. Special equipment comes to the rescue. Let us further consider what an excavator is and what is its role in the industrial economy.

Introduction

Leonardo and many other scientists tried to mechanize the process of working out the earth more than five hundred years ago. Modern machines differ in many ways, depending on the modification and intended purpose. The main classification is carried out according to the following parameters:

- Type of undercarriage (wheels, tracks, railway track, etc.).

- Operational features (for construction, quarrying, mine development, etc.).

- Power unit.

- According to the principle of action.

All these indicators can be combined in various variations, in connection with which a huge number of modifications of the technique in question have been developed.

Crawler

What is a crawler excavator? This is a car that will pass on roads with any surface, as well as without it. The vast majority of self-propelled excavatorsequipment is placed precisely on the base with a caterpillar track. The exception is analogues operating within the city. The models in question will easily overcome loose soil, peat bogs, off-road, forest and stone obstacles.

Other types of chassis

Excavators on pneumatic wheels have proven themselves to work in urban environments. Caterpillar counterparts are not suitable here, because they will simply destroy the asph alt surface. Wheeled models are not only gentle on the road, but also have excellent shock absorption, and also have a minimum noise level.

What is a walking excavator? Such a modification is devoid of tracks or wheels. At the bottom of the unit is a base plate that serves as a platform during operation. The machine moves with the help of special hydraulic shoes. She climbs them, transports herself, and lowers herself back down to the base plate. High-speed mode of movement can be up to 80 km / h.

Rail excavators are commonly used in mining. Chain models are placed on rails widely spaced between them. This distance is called the portal, it is convenient for trucks to enter it for loading.

Earth-moving universal devices can be mounted on almost any chassis. Combined modifications can be equipped with wheels and railway lowered pairs, if necessary, movement on rails. There are floating counterparts (dredges).

Operation principle

Single-bucket variations work in a cyclicmode: scored - transferred - poured out. Continuous action devices include rotary and trench excavators. The first models include units with several buckets, which are mounted on a large rotating wheel. As an example of a trench analog, one can cite lightweight units for laying cables. The dredgers collect sand under water according to the vacuum suction principle.

It is impossible to determine one optimal and universal way of working. It all depends on the type of material being mined and the environmental conditions. In each specific case, a specific type of equipment is required.

Features

We will continue the review of excavators with wheeled models for construction. Despite the fact that caterpillar modifications are leading in the field of soil development, for construction sites, units on wheels will be the best option. They are more mobile, faster, do not spoil the asph alt and are quickly transferred from one object to another.

Mine excavators have compact dimensions, which is important in confined spaces. Typically, they are used in horizontal workings underground and in tunnels for loading rocks.

The open pit operates modifications that can provide maximum movement and loading of material. Several types of machines are used in such work. The main requirement for them is that the excavator bucket be as spacious as possible. Among career models:

- Draglines. The design of these units does not provide for a rigid connection of the bucket witharrow. The scoop is held with a chain, the analogue of which pulls it up or down.

- Tracked off-road mining vehicles.

- Hydraulic versions with the ability to increase the pressure on the rock. They are usually used in stripping operations.

- Modifications of the rotary type, providing the most complete supply of minerals.

Power Plants

The study of the technical characteristics of the excavator will continue in terms of engines. The first machines were powered by a steam engine, then they were replaced by diesel, gasoline and electric motors. The most popular power units are diesel and electric. This is due to their economy.

The diesel version is mobile. This technique allows you to move a lot around the object being processed and beyond. If the process involves moving over short distances, it is wiser to use an electrical analogue. For career workings, just such a technique is just right.

Light battery-powered excavators are being developed. In this case, the machine is controlled by the operator remotely or in the traditional way.

Application

What is an excavator and why is it needed? First of all, the technique in question is an earth-moving machine, the main task of which is excavation, transfer of soil and rock. At the same time, excavators can work not only on the sites where they are located, but also on areas lower or higher. Besides,material can be mined without problems from under the water layer.

The equipment loads the resulting rock into transportation units (cars, barges, wagons). If necessary, the soil can be poured into a dump. The hydraulic excavator allows you to quickly and efficiently dig channels, trenches, pits, clear the territory with maximum accuracy. The machines in question made it possible to completely mechanize earthworks, significantly facilitating the work of people. An ordinary building model is capable of moving up to 4 cubes of earth or sand in one go.

The biggest excavators

The largest car in this category has impressive dimensions. The giant was designed and assembled by the German company Thyssen Krupp Fordertechnik in 1978. The equipment was assembled for 5 years, its cost exceeded 100 million Euros. "Monster" is still working in the coal mine Gambach.

The machine operates for about 20 hours a day, its capacity is 240,000 cubic meters. m of coal. Such volumes are quite difficult to load and take out, but this is not required. Such large excavators are required to break open a mass in which more than half of the material is unsuitable rock. The dimensions of the giant: length / width / height - 240/46/96 m. Weight - 13.5 thousand tons. Boom length - 200 m. The volume of each bucket - 6.6 cubic meters. m.

Hitachi excavator

The following are the technical parameters of one of the most productive excavators - "HitachiZX200":

- Length/width/height - 8, 94/2, 86/2, 95.

- Weight - 19.8 tons.

- Wheel base - 3, 37 m.

- Clearance - 45 cm.

- Pressure on soil - 0.47 kg/sq. see

- Depth of excavation - 6.05 m.

- Excavator bucket volume - 0.51 cu. m.

- Ultimate pulling force - 203 kN.

Hitachi ZX200 powertrain

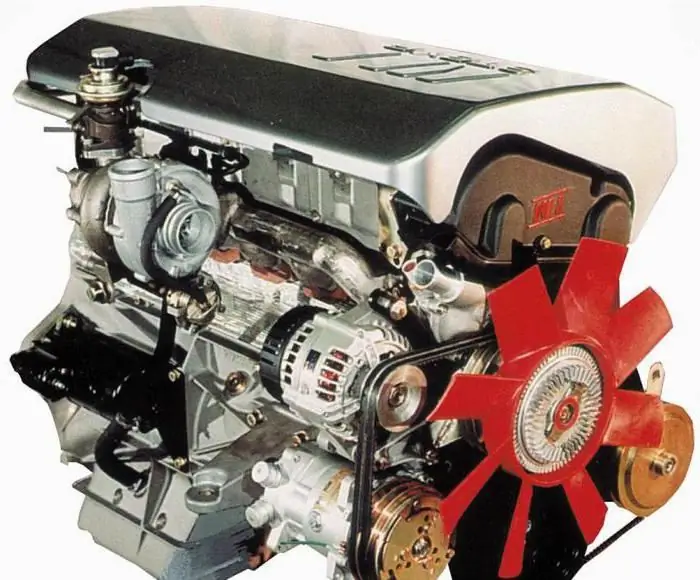

The equipment is equipped with a four-stroke diesel engine with 4 cylinders. The engine has direct fuel injection, an overhead camshaft and water-type cooling. New excavators of this modification are equipped with a power plant, which aggregates with a modern hydraulic system of the HIOS III type, which provides the possibility of programming manual and automatic modes of operation. In addition, this unit allows you to maximize the use of hydraulic pressure, increasing output with economical fuel consumption.

Main engine parameters:

- Working volume - 5, 19 l.

- Rated power - 166 horsepower.

- Torque to the maximum - 550 Nm.

- The size of the cylinder in diameter is 105 mm.

Device

The Hitachi excavator is equipped with a boom (length - 5.68 m) and a stick with increased traction and turning moment (2.91 m). Engineers have redesigned the motion control to increase engine speed automatically when maneuvering or climbing when more traction is needed.

Dimensions of the brackets on the topsupport rollers are increased. This has a positive effect on the working resource of the node. Additional rigidity of the unit is given by a modified configuration and reinforcement of the tracks. In addition, the box-section frames and the X-shaped central beam are enlarged. The whole complex of improvements added to the strength of almost 35%. The plates of the X-beam are made in the form of monolithic elements, which significantly strengthened the central part of the frame.

Result

Modernization and design improvement of excavators goes on as usual in a continuous mode. Designers continue to seek to improve the quality of work, which is due to the growth in construction and mining.

Recommended:

Caterpillar - excavator with outstanding technical parameters

Caterpillar is an excavator with optimal technical characteristics and high consumer demand. The machine is supplied to the world market by a well-known American brand in the most diverse and sometimes quite remote corners of the planet

Cat excavators: overview, specifications. Excavators

Cat excavators: overview, varieties, features, application, operation, maintenance. Caterpillar excavators: specifications, photos, dimensions, advantages. Description, parameters, purpose of this technique

Car operation is Types, characteristics, categories, depreciation and fuel consumption calculations, features of work and technical use

Logistics of road transport is an important factor in technical operation systems and is a process of supplying automobile enterprises with rolling stock, units, spare parts, tires, batteries and materials necessary for their normal operation. Proper organization of logistics plays a crucial role in improving the use of vehicles by keeping them in good condition

Overview of the GAZ-560 car and its technical characteristics

For more than ten years, we have been seeing cars in the vastness of our country on which the GAZ-560 Steyer engine is installed. Moreover, these are not only cargo "Lawns" and "GAZelles", but also passenger "Volga". What are the features of this unit? Learn from our article

What is the capacity of the excavator per hour and per shift? Calculation of the operating performance of the excavator

Before renting an excavator, you need to study its performance. This is the most important parameter that you should pay attention to in the first place