2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Most motorists are familiar with such an automotive component as a cardan shaft. It is thanks to the cardan gear that the wheels can rotate. More correctly, this is a mechanism that serves as a torque transmitter from the power unit to the gearbox on the front or rear axle. The cardan shaft device is very simple, if not primitive. The design of this element has not changed for about 100 years. Cardan repair is also carried out according to the same scheme.

How does the mechanism work?

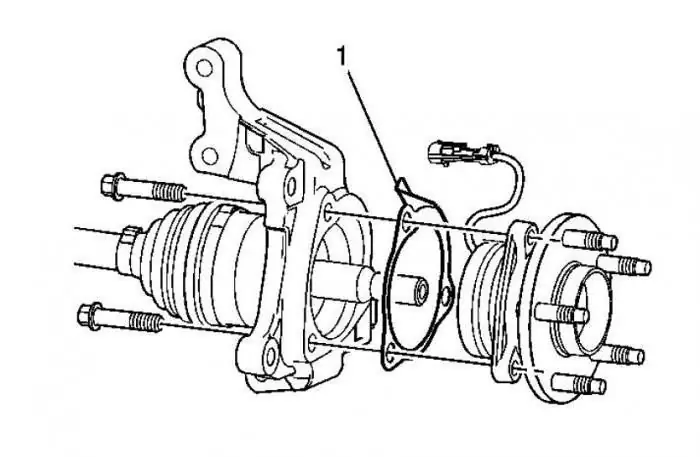

The mechanism includes several parts. So, this is the shaft itself, fasteners, as well as a cross, an outboard bearing and other elements, depending on which car it is intended for.

It can consist of two, three or more sections. Geometry varies by vehicle model.

Working principle

He is very, very simple. All the work of the shaft in transmitting torque is performed using swivel joints. So, rotational energy can be transferred from the gearbox shaft to axles,if the shafts are in different planes. The hinges are crosses. It is thanks to them that rotation occurs at variable angles. This part often breaks down and needs to be repaired. Replacement of universal joint crosses is necessary if the angle of rotation is more than 20 degrees. The part is subjected to enormous loads and wears out very quickly. As a result, the shaft loses its balance, knocks and vibrates.

The replacement operation is quite simple, and the shaft itself is one of the most maintainable mechanisms in a car. Removing this design is very easy. Repair consists in installing new components.

Replacing the cardan crosses: how to understand what time it is?

This component is considered one of the main parts of the design. It is she who is entrusted with the main role in transferring rotational energy from the source to the working mechanism of the bridges. If the spider is only slightly worn, then the shaft can no longer effectively perform its tasks.

In this situation, there is a serious risk of breakdowns and other components in the car. Also, a broken part significantly reduces the safety of movement in such a car.

So, the replacement of the cardan crosses is required if characteristic ringing metal knocks, various knocks, tangible vibrations in the running systems are heard from under the bottom of the car. You can also diagnose by intermittent whistling sounds when the engine is running at low speeds. If you drive the car onto a flyover, raise it with a lift, you can notice a noticeable backlash. If you hear a knock when you press or release the accelerator pedal, this is alsosignal for an ambulance replacement.

Easy Solutions

Often, the recovery operation is carried out very quickly. For example, if extraneous knocks are heard when starting from a standstill, switching gears, speeding up, then most likely you just need to tighten the threaded connections where the flange connects to the driveshaft coupling.

Cardan repair in this case is a thread broaching. This is often more than enough. If knocks are still heard, then the reason is different. One option is a gap in the shaft spline connection or in the needle bearing of the spider. If in the first option it is enough to replace the damaged elements, then in the second one everything is solved by installing a new mechanism.

Replacing the cardan crosses will not cause any difficulties even for novice motorists. Everyone has all the tools for this operation in the garage.

Required set of tools

All work consists of several stages. You also need a set of open-end wrenches, a hammer and a chisel of the right size, sockets depending on the model of the car, a set of screwdrivers, a tool for removing circlips, a brush for cleaning metal products, pliers, a syringe and grease for universal joints and crosses.

When everything is in stock, get a repair kit for your shaft. It will already include the necessary spare parts.

These are the crosses themselves, "bochat", and a large number of retaining rings. You should also purchase suitable bolts and nuts.

Better everyone do thiswork on a pit, overpass or lift. But you can do without all this, but lying under the car is not very convenient. It will not be superfluous to invite an assistant. This way everything will turn out much faster.

Replacement process

So, the first stage is the preparatory work. By now, you should have collected and bought everything.

So, the cardan cross (price for VAZ models) in any auto shop will cost only 500 rubles. Next up is demolition work. Here the shaft itself and the crosses are removed.

Before you start dismantling, you should mark exactly where the forks are located. To do this, you have prepared a hammer with a chisel. These actions will then make it much easier for you at the assembly stage. If you do not make these marks, then an inaccurate installation is possible. This threatens the appearance of beats and vibrations. Of course, this happens quite rarely, but in order to avoid problems in the future, take the above advice into account.

Remove the shaft

There are several ways to remove the shaft. So, you can disconnect the rear part with an open-end wrench, and then remove the bolts holding the intermediate support and the elastic coupling. Now you can easily remove the shaft.

The second option is even easier. Screwdrivers are used for this. Using a tool, bend the tabs securing the casing to the protective cuff. Further, the shaft can be simply and conveniently pulled out of the flange.

How to remove the crosspiece?

Here is the cardan and removed. Now we remove the cross. To begin with, the retaining rings are removed,then the cardan is rotated so that the part is on top. This makes it easier to dismantle it. A mandrel and a hammer will help you. Knock out the bowl of the cross, but not much. Knock carefully. As soon as the bowl starts to move, you can pull it out with tongs.

Do the same operation for the second bowl. Be sure to clean the cardan from dirt and grease. It is also recommended to clean the places under the retaining rings. Everything, the old part can be thrown away. Repair of universal joint crosses is not provided.

Installation

This process is recommended to start by removing the cuff from one spike and beyond. Work very carefully and carefully. Each part must be generously lubricated. It is advisable to replace the old fastener with a new one. When installing, make sure that there are no distortions. This is fraught with additional expenditure of finances and forces.

How to maintain the mechanism: lubrication for crosses and universal joints

As for lubricants, professionals advise using grease No. 158 for these purposes, or any available analogue of this product. Previously, mechanisms were equipped with oilers for lubrication. Perhaps they are also in new products. Grease should be in large quantities in the crosspieces.

Also, for long and reliable operation, it is recommended to generously lubricate the splined movable joint.

Replacing the VAZ cardan cross. How to choose a quality part?

These cars are front-wheel drive, but the process of dismantling, replacing and reassembling is no different from the above diagram.

Whenbuying this spare part, you can run into unscrupulous sellers or a manufacturing defect.

A mirror will help you choose. Lay it on a hard and level surface, and place a cross on top. Holding the opposite ends of the part with your fingers, swing it. If no play is found, then check the other side. This item is 100% high quality.

Recommended:

Starter VAZ-2105: problems and solutions, replacement and repair rules, expert advice

VAZ-2105 is still popular with Russian drivers. It is distinguished by ease of operation and low cost of spare parts. However, if the car owner wants the car to work without problems, he must regularly check it for various faults

KAMAZ 740 crankshaft: device and dimensions, repair, replacement

Crankshaft "KAMAZ 740": device, features, photos, operation, dimensions, maintenance. Crankshaft "KAMAZ 740": characteristics, repair, replacement, bearings. Comparative characteristics of the crankshaft "KAMAZ 740" and its analogues

Internal liners for different cars: replacement, repair, installation

Main bearings, represented by plain bearings, are of great importance for the operation of the engine: first of all, they provide ease of rotation of the crankshaft. At the same time, they are subjected to significant loads, which over time can lead to their displacement from the installation site

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Car "Gazelle" rear axle: diagram, replacement, repair and recommendations

On the domestic Gazelle car, the rear axle is equipped with a separately modeled gearbox and a stamped-welded crankcase. The last element has a box section, welded from shell-shaped steel plates