2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

The gas distribution system is one of the main components of any engine. It includes a chain or belt drive. The latter is less noisy, but at the same time less reliable. The chain never breaks. But it can make noise while working. Today we will look at how the ZMZ-406 timing chain is replaced and what this element is.

Characteristic

This part is the basis of the engine. It is thanks to the chain that you can correctly install the timing phases ZMZ-406. Recall that these are intake, compression, stroke and exhaust. In order not to bend the valves and ensure maximum efficiency, a special chain is used.

It is she who distributes the forces to the camshaft, which opens and closes the engine valves at the right time. Thus, the ZMZ-406 timing system ensures the timely supply of the combustible mixture to the combustion chamber and their exit after the third cycle (power stroke). The result is a powerful and economical engine.

Where is it?

Timing chain ZMZ-406 is located on the pulleycrankshaft. It rotates simultaneously with it when the engine is running. Special timing chain dampers ZMZ-406 are also used. They provide the necessary tension to the mechanism.

If it becomes unusable, the ZMZ-406 timing phases will be installed incorrectly. The chain will stretch or jump a few teeth. During the operation of the mechanism, a water pump, a hydraulic booster (not on all Gazelles) and an intermediate shaft of the ignition system are activated. With each of these elements, the ZMZ-406 timing chain is closely connected.

About timing problems

The main signs of failure are a decrease in engine power, characteristic pops in the exhaust and intake manifolds, as well as a low level of compression. It should not be less than 10 kilograms per square centimeter. But it is not necessary to buy a new timing kit ZMZ-406. Perhaps only the chain failed. By the way, when it malfunctions, it emits metallic knocks. Such malfunctions of the timing ZMZ-406 can be provoked by a loose fit of the valve seats. As a result, carbon deposits form, valve springs fail. The gap between the rocker arm and the valve stem is not correct. If the engine does not provide sufficient valve opening, this can cause damage to the hydraulic lifters. The gear of the crankshaft and camshaft also wears out. As a result, it is necessary to repair the ZMZ-406 engine. Timing is a serious mechanism. To avoid trouble, it is necessary to monitor the chain tension and adjust the damper. itmust be done at least once every 80 thousand kilometers. A chain, unlike a belt, is a fairly reliable mechanism. It does not tear and does not provoke bending of the valves, but only stretches during prolonged use. The resource of the gas distribution mechanism chain is about 200 thousand kilometers. The resource of the belt does not exceed 80 thousand. But if you have characteristic symptoms at 150 thousand (meaning the metal knocks of the chain), do not hesitate to replace it. Below we will look at how to repair this system with our own hands.

Tools

To successfully replace the ZMZ-406 timing belt, we need to prepare a set of tools. We will need a set of sockets and hex keys, a torque wrench, a hammer and a chisel. Next, consider the phased process of replacing the timing chain ZMZ-406.

Preparatory work

First we need to prepare containers for draining working fluids. First we pour out antifreeze. The GAZelle contains a lot of it, about ten liters. It merges by unscrewing the plug at the bottom of the radiator. Be careful - at first antifreeze will run with great pressure. As it pours, it will get smaller. It is recommended to use a bulk canister or bucket. It is important that the container is clean. For a better exit of antifreeze, unscrew the cap on the expansion tank.

What's next?

After that, remove the front apron with the grille (if it is a "business" bumper, unscrew its mounts in the center and on the sides). Next, remove all clamps and pipes that lead to the radiator. We dismantle the last element. If ayour car is equipped with a hydraulic booster, you need to remove the power steering pump drive belt.

We also take out the alternator and pump belt, after loosening the tension. Now remove the cylinder head valve cover. All bolts must be folded into a separate box or niche. This will not affect the repair in any way, but will significantly speed up the assembly process. You do not have to look for where the missing bolt or nut lies, as is often the case. Next, unscrew the viscous fan coupling with the impeller itself.

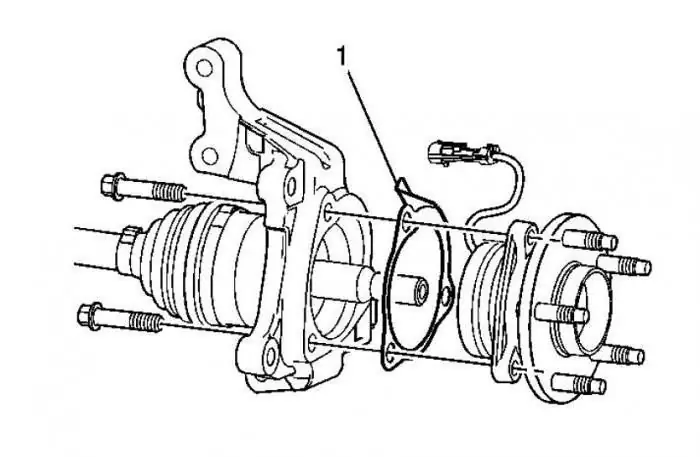

It is recommended to put the valve cover in a clean and dry place. The presence of dust on its inner side is highly undesirable. Next, the pump and the crankshaft rotation sensor are removed (do not forget to install it in place, otherwise you simply will not start the engine). The next step is to remove the crankshaft pulley and oil pan. Then unscrew the two mounting bolts of the chain tensioner. The last element comes out. In total, there are two hydraulic tensioners on the 406th and 405th motors - upper and lower. We need to get both mechanisms. The lower one is disassembled in the same way. Next, we need to remove the chain cover. It is attached with seven bolts. Be careful - you can damage the front crankshaft oil seal and cylinder head gasket. We unscrew the bolt of the upper tensioner and remove the lever with an asterisk. Next, we unscrew the plastic timing chain damper ZMZ-406. We unscrew the bolts securing the gears to the camshaft flange (there are two of them in this motor). Next, we need another tool. To remove the bottom gear,you need to install a negative screwdriver (it will serve as a lever) between it and the second gear.

We bend the end of the locking plate, and, holding the intermediate shaft, insert our tool. We take out the gears and the lower part of the chain from the crankshaft. If there are difficulties with dismantling, it is required to remove the rubber seal between the gear and the bushing. The last element is also dismantled. The second gear is pressed with a puller.

After the chain was removed

So, we get the element out. The chain must be thoroughly washed in gasoline and cleaned of dirt. Check out her appearance. After 150 or more thousand kilometers, it stretches by 1-2 centimeters. This is quite enough to provoke improper gas distribution. If there are signs of wear, scuffs and cracks on the mechanism bushings, the mechanism is not subject to further operation. If there are chips on the gears, we also change them for new ones. Check the condition of the dampeners. If there is any damage, replace the element with a new one. Check the tensioner sprockets. They must rotate freely on their axis. There should be no scratches or chips on the work surface.

Reverse assembly

First you need to set the valve timing correctly. To do this, scroll the crankshaft until the first mark on it coincides with the second on the cylinder block. The piston of the first cylinder should be at top dead center. Next, install the chain guide. We don't tighten the bolts yet. Lubricate with machine oilthe lower chain and put it on the driven gear and crankshaft. We install the penultimate one so that the pin enters the hole in the intermediate shaft. The mark on the gear must match the one on the cylinder block. In this case, the part of the chain that passes through the damper will be stretched. We twist the fixing bolts of the gears of the intermediate shaft. A locking plate is installed under them.

Recommended to use a torque wrench. Tightening torque - from 22 to 25 Nm. When the bolt is tightened with the right moment, this key will start to click - go to the second element. Do not forget to fix both bolts with a locking plate. We bend its edges with a hammer and chisel. Next, we press the tensioner lever and check if the marks on the cylinder block and on the gear coincide. Tighten the damper bolts and lubricate the upper chain. We put it on the gear of the intermediate shaft. We scroll the camshaft clockwise. We put the chain on the second gear. The camshaft pin should enter its hole.

Charging points and marks

Using a square wrench, turn the camshaft counterclockwise. We stretch the timing chain. The crankshaft and intermediate shaft must not rotate. The marks will line up with the top surface of the cylinder head. Remove the gear from the exhaust camshaft and install the chain on it. Then we put it back, slightly turning the shaft clockwise. The pins must go into the gear hole. We rotate the shaft counterclockwise, pulling the timing chain. Next install the chain cover andwater pump. A small layer of sealant should be applied to the top of the cover. Be careful not to damage the front crankshaft oil seal when installing. Next, two hydraulic tensioners and a crankshaft pulley are mounted. On the latter, it is necessary to observe the tightening torque - from 104 to 129 Nm.

In this case, you need to turn on the 5th gear and the parking brake. Hold the crankshaft so that it does not turn. Next, the ratchet is tightened. The latter scrolls two turns. The crankshaft is set to the top dead center position (regarding the first cylinder). Next, install the cylinder head cover. A layer of sealant must be applied to it to prevent oil leaks. The cover is tightened with a torque of about 12 Nm. Next, you need to connect the crankcase ventilation pipe to the fitting on the valve cover. We connect the wires to the ignition coils and put their ends on the candles. We fill back the antifreeze, put the radiator in place and start the engine. If everything was done correctly, the metallic sounds will disappear and the engine power will return to normal. This completes the process of repairing the gas distribution mechanism. The best timing ZMZ-406 is the one on the chain. To the belt drive, many car owners are still skeptical. Chain drive is much more reliable. But practice shows that it is losing popularity every year, especially among foreign manufacturers.

Problems during installation

There were cases when the head gasket was damaged during the repair of this mechanism. In this case, it is necessary to cut off its remains with a clerical knife anduse sealant. Also, with this tool, it is necessary to process all the sealing parts of the cover. Sealant drying time - 24 hours.

Conclusion

So, we found out what the gas distribution mechanism is on the GAZelevsky 406th engine. As you can see, replacing the chain does not require additional tools. But in time it takes all day. Therefore, it is worth planning such repairs in advance. At the service station, this service takes about 5 hours. Its cost is six thousand rubles. The very same set of gas distribution mechanism costs about five thousand. It includes chains (small and large), hydraulic tensioners, dampers and camshaft sprockets.

Recommended:

Chevrolet Aveo timing belt replacement: timing and frequency, job description and auto repairman's advice

In the article we will talk about the nuances of replacing the timing belt on a Chevrolet Aveo. The problem with all the engines of this car is that when the belt breaks, all the valves bend. And the cost of repairing a cylinder head is much higher than replacing a belt, rollers, and even a liquid pump combined. After all, you have to buy a set of new valves, seals for them, grind

What is a timing chain? Which is better: timing chain or belt?

Now there is a lot of controversy about which timing drive is better - a timing belt or a timing chain. VAZ used to be equipped with the latest type of drive. However, with the release of new models, the manufacturer switched to a belt. Now many companies are moving to use such a transfer. Even modern units with a V8 cylinder layout are equipped with a belt drive. But many motorists are not happy with this decision. Why is the timing chain a thing of the past?

Replacing the timing chain on the Chevrolet Niva with your own hands: step by step instructions with a photo

One of the most important components in an engine is the timing system. Today, manufacturers are increasingly switching to belt drive. However, many domestic cars are still equipped with a chain gas distribution mechanism. Chevrolet Niva is no exception. The manufacturer recommends replacing the timing chain on the Niva Chevrolet every 100 thousand kilometers

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Engine oil change: frequency, replacement timing, oil selection and procedure

The basis of every car is its engine, which must run like clockwork. Engine oil helps to avoid premature wear of parts, which lubricates its parts and minimizes friction between them. You can read more about how often you need to change engine oil and how to do it yourself in this article