2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

The piston is one of the elements of the crank mechanism, on which the principle of operation of many internal combustion engines is based. This article discusses the design and features of these parts.

Definition

A piston is a part that performs reciprocating movements in a cylinder and ensures the transformation of gas pressure changes into mechanical work.

Destination

With the participation of these parts, the thermodynamic process of the motor is realized. Since the piston is one of the elements of the crank mechanism, it perceives the pressure produced by the gases and transfers the force to the connecting rod. In addition, it ensures the sealing of the combustion chamber and the removal of heat from it.

Design

The piston is a three-piece part, that is, its design includes three components that perform different functions, and two parts: the head, which combines the bottom and sealing part, and the guide part, represented by the skirt.

Bottom

May have differentform depending on many factors. For example, the configuration of the bottom of the pistons of an internal combustion engine is determined by the location of other structural elements, such as nozzles, candles, valves, the shape of the combustion chamber, the features of the processes occurring in it, the overall design of the engine, etc. In any case, it determines the features of operation.

There are two main types of piston crown configuration: convex and concave. The first provides greater strength, but worsens the configuration of the combustion chamber. With a concave bottom, the combustion chamber, on the contrary, has an optimal shape, but carbon deposits are deposited more intensively. Less commonly (in two-stroke engines) there are pistons with a bottom represented by a reflector protrusion. This is necessary when blowing for the directed movement of combustion products. Parts of gasoline engines usually have a flat or almost flat bottom. Sometimes they have grooves to fully open the valves. In engines with direct injection, the pistons are characterized by a more complex configuration. In diesel engines, they are distinguished by the presence of a combustion chamber in the bottom, which provides good swirl and improves mixture formation.

Most of the pistons are single-sided, although there are also double-sided versions that have two bottoms.

The distance between the groove of the first compression ring and the bottom is called the firing zone of the piston. The value of its height is very important, which is different for parts made of different materials. In any case, the height of the ring of fire beyondthe limits of the minimum allowable value can lead to burnout of the piston and deformation of the seat of the upper compression ring.

Seal part

Here are oil scraper and compression rings. For parts of the first type, the channels have through holes for the oil removed from the surface of the cylinder to enter the piston, from where it enters the oil pan. Some have a stainless steel rim with a groove for the top compression ring.

Piston rings, made of cast iron, serve to create a snug fit between the piston and the cylinder. Therefore, they are the source of the greatest friction in the motor, the losses from which amount to 25% of the total mechanical losses in the motor. The number and location of rings are determined by the type and purpose of the engine. The most commonly used are 2 compression rings and 1 oil scraper ring.

Compression rings perform the task of preventing gases from entering the crankcase from the combustion chamber. The greatest loads fall on the first of them, therefore, in some engines, its groove is reinforced with a steel insert. Compression rings can be trapezoidal, conical, barrel-shaped. Some of them have a cutout.

The oil scraper ring serves to remove excess oil from the cylinder and prevents it from entering the combustion chamber. It has holes for this. Some variants have a spring expander.

Guide part (skirt)

Has a barrel-shaped (curvilinear) or conical shape to compensate for thermal expansion. On herthere are two lugs for the piston pin. In these areas, the skirt has the greatest mass. In addition, there are observed the greatest temperature deformations during heating. Various measures are used to reduce them. There may be an oil scraper ring at the bottom of the skirt.

To transfer force from the piston or to it, most often a crank or a rod is used. The piston pin serves to connect this part to them. It is made of steel, has a tubular shape and can be installed in several ways. Most often, a floating finger is used, which can be rotated during operation. To prevent displacement, it is fixed with retaining rings. Rigid fastening is used much less frequently. The rod acts as a guide in some cases, replacing the piston skirt.

Materials

The engine piston can be composed of various materials. In any case, they must have such qualities as high strength, good thermal conductivity, anti-friction properties, corrosion resistance and low coefficient of linear expansion and density. For the production of pistons, aluminum alloys and cast iron are used.

Cast iron

It features high strength, wear resistance and low coefficient of linear expansion. The latter property enables such pistons to operate with close clearances, thereby achieving good cylinder sealing. However, due to the significant specific gravity, cast iron parts are used only in those engines where the reciprocating masses have forcesinertia, constituting no more than a sixth of the pressure forces on the bottom of the gas piston. In addition, due to low thermal conductivity, the heating of the bottom of cast-iron parts during engine operation reaches 350-450 ° C, which is especially undesirable for carburetor options, as it leads to glow ignition.

Aluminum

This material is used most often for pistons. This is due to the low specific weight (aluminum parts are 30% lighter than cast iron parts), high thermal conductivity (3-4 times greater than that of cast iron), which ensures that the bottom is heated to no more than 250 ° C, which makes it possible to increase the compression ratio and provide better filling of cylinders, and high antifriction properties. At the same time, aluminum has a linear expansion coefficient that is 2 times greater than that of cast iron, which forces large gaps to be made with the cylinder walls, that is, the dimensions of aluminum pistons are smaller than those of cast iron for identical cylinders. In addition, such parts have lower strength, especially when heated (at 300 ° C, it decreases by 50-55%, while for cast iron - by 10%).

To reduce the degree of friction, the walls of the pistons are coated with an anti-friction material, which is used as graphite and molybdenum disulfide.

Heating

As mentioned, during engine operation, pistons can heat up to 250-450 °C. Therefore, it is necessary to take measures aimed at both reducing heating and compensating for the thermal expansion caused by it.details.

To cool the pistons, oil is used, which is supplied inside them in various ways: they create an oil mist in the cylinder, spray it through a hole in the connecting rod or with a nozzle, inject it into the annular channel, circulate through the tubular coil in the piston bottom.

To compensate for temperature deformations in the areas of the tides, the skirts are turned on both sides of the metal 0.5-1.5 mm deep in the form of U- or T-shaped slots. Such a measure improves its lubrication and prevents the appearance of scoring from temperature deformations, therefore these recesses are called refrigerators. They are used in combination with a conical or barrel-shaped skirt. This compensates for its linear expansion due to the fact that when heated, the skirt takes on a cylindrical shape. In addition, compensation inserts are used so that the piston diameter experiences limited thermal expansion in the swing plane of the connecting rod. It is also possible to isolate the guide part from the head that experiences the most heat. Finally, the walls of the skirt are given springy properties by applying an oblique cut along its entire length.

Production technology

According to the manufacturing method, pistons are divided into cast and forged (stamped). Parts of the first type are used on most cars, and replacing pistons with forged ones is used in tuning. Forged options are characterized by increased strength and durability, as well as lower weight. Therefore, the installation of pistons of this type increases the reliability and performance of the engine. This is especially important for motors operating in conditions of increasedloads, while cast parts are enough for everyday use.

Application

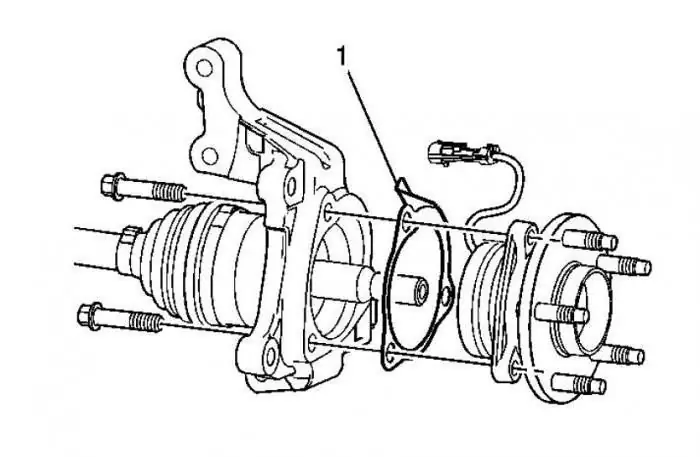

The piston is a multifunctional part. Therefore, it is used not only in engines. For example, there is a brake caliper piston, since it functions in a similar way. Also, the crank mechanism is used on some models of compressors, pumps and other equipment.

Recommended:

Installation of another engine on the car. How to arrange an engine replacement on a car?

Very often, drivers who are not satisfied with the dynamic characteristics of the motor or its other parameters make the replacement of the power unit with a more suitable one. It would seem that everything is simple, but in fact it is far from it. Firstly, installing another engine on a car requires a large number of technical alterations. Secondly, do not forget about the documents, because the other internal combustion engine has its own serial number. But let's talk about everything in order

Starter - what is this part in a car?

Every more or less experienced driver knows perfectly well that the starter is the primary engine start device, without which it is very difficult (but not impossible) to start the engine, to put it mildly. It is this element that allows you to create the initial rotation of the crankshaft at the desired frequency, so it is an integral part of any modern car or other device that uses an internal combustion engine

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Checkpoint is the most important part of a car

Checkpoint is the most complex technical mechanism designed to shift gears in a car. No car is able to continue moving without a gearbox. Today there are automatic and manual transmissions. The last one came out first. It is still used in many cars today

Fuel filter for a diesel engine: device, replacement, principle of operation

The engine power system includes a lot of important elements, including filtering ones. They are present on both gasoline and diesel engines. As for the latter, such engines are more demanding on fuel quality. Therefore, the diesel engine fuel filter device is slightly different from gasoline counterparts. So, let's look at the design and purpose of these elements