2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

Rear caliper guides are needed for several tasks. Firstly, they are responsible for the absence of the ringing of the car's brakes, and secondly, for the uniformity of braking. The main problem is that this element wears out quite quickly, although a lot depends on the brand of the car. Let's see how to lubricate and, if necessary, change the caliper guides yourself.

Some general information

Before starting work, you need to decide what, in fact, is the problem. But the thing is that the hum and creak during braking can occur for several banal reasons. As a rule, this is a critical wear of a part or a complete or partial lack of lubrication under the anther. This work can be called easy in terms of complexity, the only problem may arise if the anthers are stuck, but this is quickly solved. To begin with, it is desirable to installvehicle to a viewing hole or use a lift. In most cases, a conventional jack will suffice. We remove the wheel and see our actual problem area, which we will have to work with in the near future. If everything is very dirty and nothing is clear, then we pick up a metal brush and carefully clean everything. Be careful not to damage the dust boots as they are made of thin rubber.

Required tools

Let's get straight to the tools. The first step is to find the original repair kit for the rear caliper, which consists of a number of spare parts, such as the guide and piston boot, grease, cuff, etc. To make the replacement and lubrication process take as little time as possible, get a hammer and a flat screwdriver, preferably have a set of heads and a torque wrench with you. A clean rag should be on hand, as you will have to work with grease. If the room is dark, then install additional lighting, you can use a special lamp, it will be much more comfortable. Now we can move on to the practical part of solving the problem. To do this, remove the rear wheel from the car, having previously raised the side with a jack and installed anti-rollbacks in front of the vehicle.

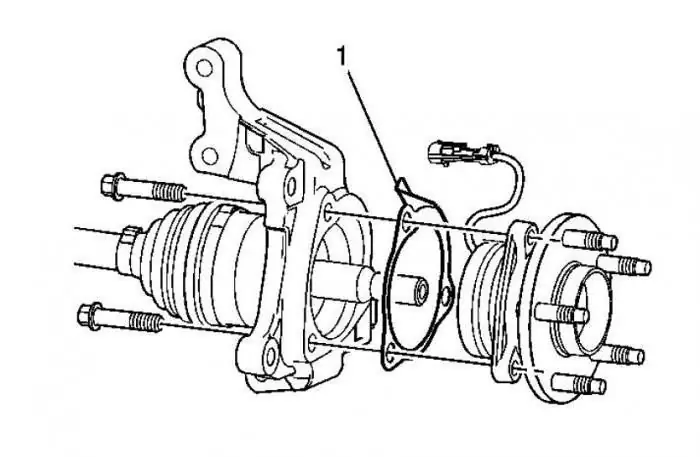

Replacing caliper guides

We unscrew the bolts from all guides using the appropriate key, there are 4 of them. To do this, you need to use two tools: with one of them, turn the outer bolt, and with the second, hold the nut from turning. After completing this step, you should be able to move the caliper up without any problems. It often happens that it comes out of the blocks rather tight. To solve this problem, use a hammer and light blows, shaking the device in different directions, take it to where you need it. After that, the guides of the rear calipers can be removed without any problems, because they are kept only on the anther. Its dismantling is carried out quite quickly and simply. It is enough to touch the rubber element with a screwdriver and remove it. Please note that the upper finger, unlike the lower one, has a step in the seat that creates play. When assembling, do not mix them up. This completes the replacement of the caliper guides, you can proceed to the next step.

Repair work continues

If you notice that the brake caliper guides are rusty, then immediately change them. If the condition is satisfactory, then you can leave. Don't forget to dismantle the guide pads, as a rule, they snap directly into the caliper bracket. Now let's start cleaning the removed elements. To do this, you can use sandpaper (fine-grained). Before applying lubricant, degrease the parts. Do not forget to carry out exactly the same actions with the guide pads, since during operation dirt and water get under the anther, which significantly reduces the performance properties of lubricants. After that, you can install new parts, or old ones, at your discretion. After the assembly is assembled, take a metal brush and go over the brakes, look atthe degree of wear of the pads, it is possible that soon they will have to be changed.

Which lubricant to choose?

The question is quite delicate for any motorist. In order for the caliper guides to work under normal conditions and ensure proper safety while driving, it is recommended to use high-temperature grease. This will almost completely eliminate the possibility of jamming or seizing of the brake pads while driving. When you carry out repairs, be sure to pay attention to the condition of the guide boot. The fact is that dirt and other foreign inclusions get under it. The grease is washed out and loses its original properties. If the guides of the front calipers are wedged, then with a probability of 99% we can say that the matter is in the lubricant. Every brake pad replacement should include a guide inspection. Remove the boot, remove the layer of old grease and apply a new one to the degreased surface. Staples, as well as the metal surfaces of the pads, must also be processed. For this, anti-charge paste is used. Lubrication can be with the inclusion of copper or with the addition of ceramics (magnesium, disulfide).

How to properly lubricate caliper guides

If you haven't done this in a while, now is the time. First you need a tube of lube. If you purchased a repair kit, then there it is. The paste is orange. If grease for guides in auto shopsI can’t find what happens most often, then we buy high-temperature paste, several sachets of 6 grams. First remove the two caliper guides and clean them from dust and dirt. If possible, it is desirable to change the anthers. If you will not install new ones, then remove the old ones, wash them and dry them. Lubricant is applied to the finger in a thin layer over the entire surface. Under the anthers, you also need to apply a little lubrication. By the way, do not overdo it, because there is no sense in the fact that the layer will be large. You can put a little paste in the anthers and immediately before installing them. If there are defects on the rubber, then the spare parts must be changed, because they will not cope with their immediate task, the problem with the creak will soon reappear. Let's move on to the next question - this is the installation of a "non-native" guide on the car.

About installing a finger on a car

As noted above, if you notice a knock, squeak or other unpleasant sound in the area of \u200b\u200bthe brake mechanisms of your car, then most likely it is the pads or guides. There are 3 ways out of the situation. Just lubricate everything, install a new repair kit (quite expensive) or, if the guides are worn out, put new ones, but from another car. If the finger is longer than needed, no problem. You can use a metal file and cut it to the desired thickness. After that, it is necessary to remove all burrs from the machined edge so that jamming does not occur during operation. As showspractice, if the diameter of the brake disc is the same, then problems should not arise. Likewise, the boot of the guide caliper should sit on the new "finger" without any undue effort.

Knock control measures

Most users complain about the reappearance of knocking after a comprehensive replacement of caliper guides or lubrication. In this case, you can take some measures, for example, use a special aluminum tape, but this will only help for a few thousand kilometers. Another good way is to simply install the brackets on the caliper. In some cases, they already exist, but if not, then in most cases it is this method that helps to solve all problems with creaking or knocking. If you perform all the actions in the complex, then the result will be positive. To do this, you need to change the guides, lubricate them before installation, also pay attention to the anthers, or rather, their condition. Install the brackets (springs) and enjoy the result.

A few important points

If, after removing the guide calipers, you notice that the fingers are very worn out, then it does not make sense to repair them, it is easier to replace them. It will be faster and cheaper. Remember that during urban or aggressive driving with frequent braking, you need to buy a lubricant that does not change its composition and properties with increasing temperature. The reason for this is that discs can heat up to 300 degrees Celsius and even higher. As for the repair itself, it's quitean expensive procedure, which is not always appropriate. However, if you still decide on it, then purchase repair guide pins and drills of a suitable diameter. The whole point is that the purchased finger has a diameter of 10 mm with a standard 9.5 millimeters. It is bored, lubricated and put back into place.

Conclusion

This article has said a lot about how to replace guides with your own hands. Nothing will work without lubrication, and if it does, it will be for a very short time, due to the high coefficient of friction and temperature, which will quickly damage anthers and other parts. Again, the process of replacing rear and front calipers and repairing them is fundamentally no different. It is also important to know that the finger - the caliper guide - has a hole from which you need to get the grease and put a new one in there for more efficient operation. Install all parts in reverse order from removal, tighten everything well. The fingers should move freely on the working surface, but not hang out, that is, without play. Check if the knock has disappeared, then you have achieved your goal. If the problem persists, you need to contact a qualified specialist for help.

Recommended:

Chevrolet Aveo timing belt replacement: timing and frequency, job description and auto repairman's advice

In the article we will talk about the nuances of replacing the timing belt on a Chevrolet Aveo. The problem with all the engines of this car is that when the belt breaks, all the valves bend. And the cost of repairing a cylinder head is much higher than replacing a belt, rollers, and even a liquid pump combined. After all, you have to buy a set of new valves, seals for them, grind

Caliper for VAZ-2108: device, types, repair

Efficient braking is one of the components of safe driving. Most modern cars use a brake disc and caliper in their design. VAZ-2108 is no exception. The situation when the car starts to stop skewed to one side due to the fault of this device is a frequent occurrence. The article will discuss the causes of uneven braking and troubleshooting methods

Starter VAZ-2105: problems and solutions, replacement and repair rules, expert advice

VAZ-2105 is still popular with Russian drivers. It is distinguished by ease of operation and low cost of spare parts. However, if the car owner wants the car to work without problems, he must regularly check it for various faults

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

What is a lubrication system?

In order to reduce the friction between the various mating parts of the car, especially the engine parts, to extend their durability and improve performance, a lubrication system is needed